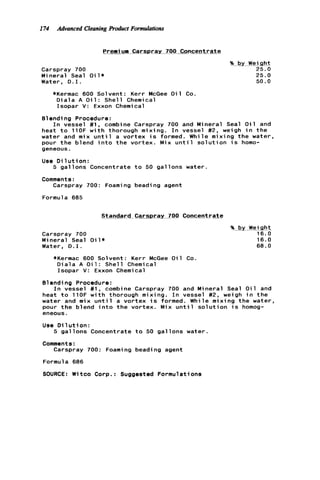

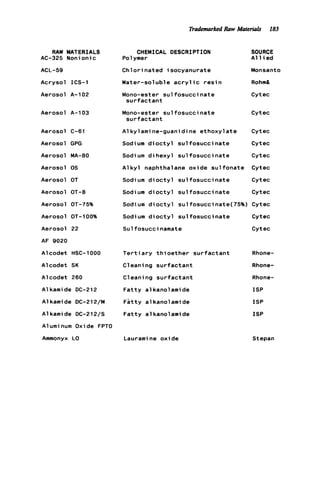

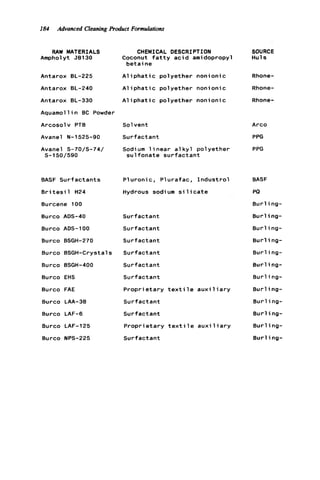

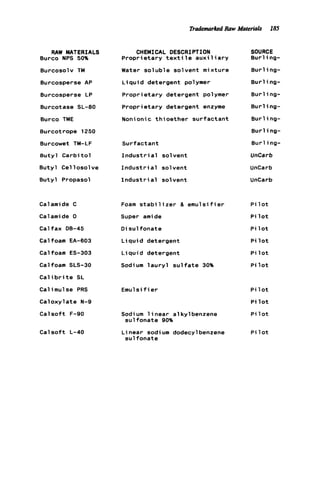

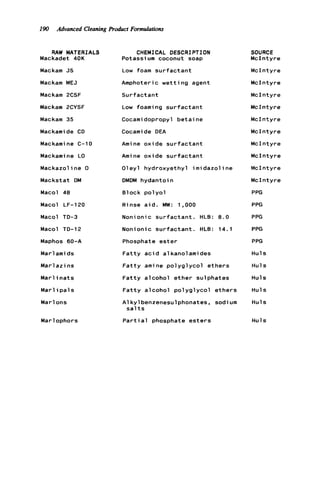

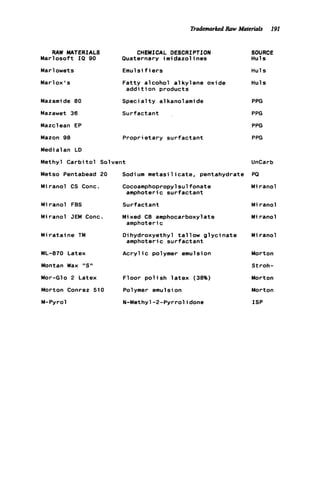

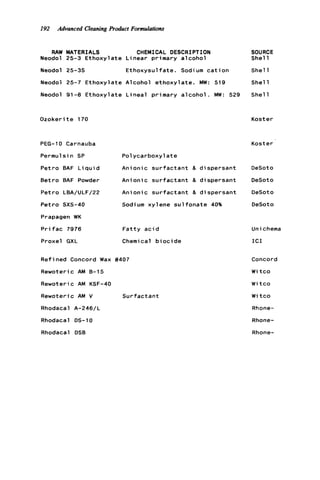

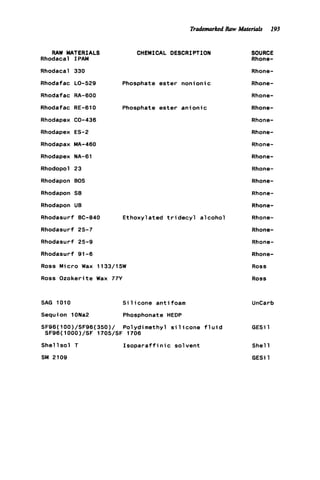

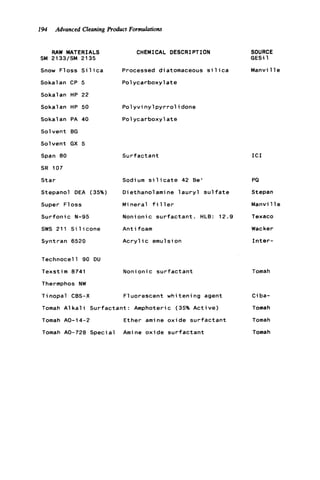

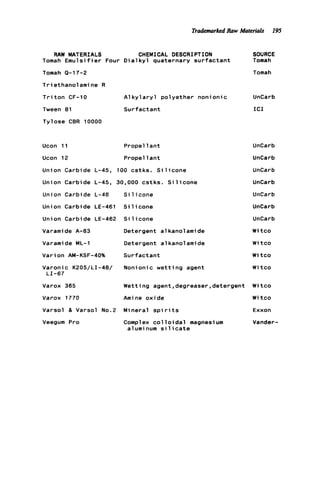

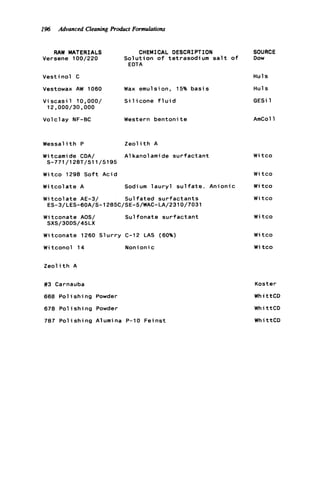

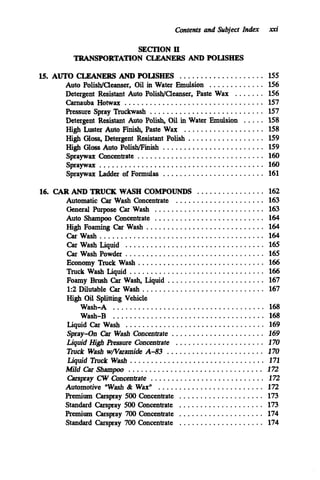

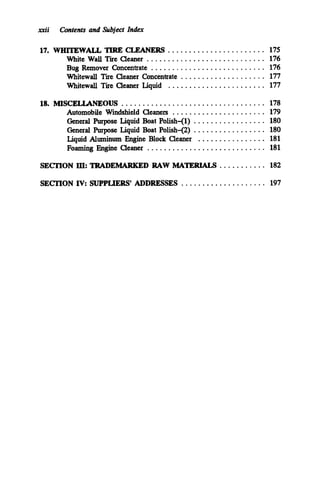

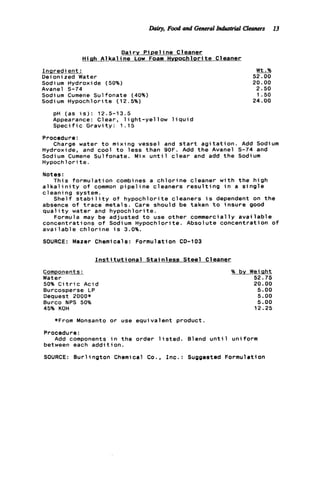

This document presents more than 435 advanced cleaning product formulations across various categories like household cleaners, industrial cleaners, automotive cleaners, and more. The formulations are divided into sections and chapters indicating their end use applications. Each formulation provides the raw materials used, their percentages, key properties, and source of the information. The book also includes a section listing details of the trademarked raw materials and contact information of their suppliers.

![Polishes, Coatings and Finishes 125

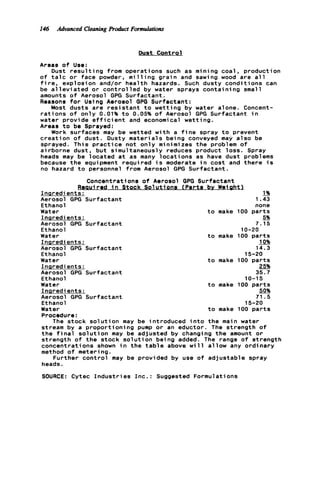

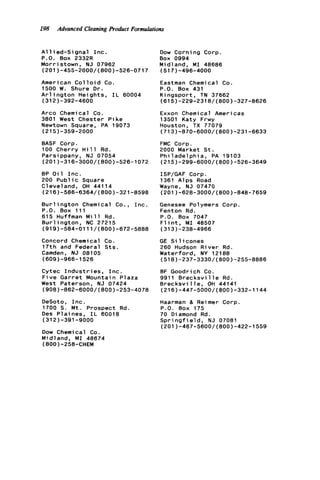

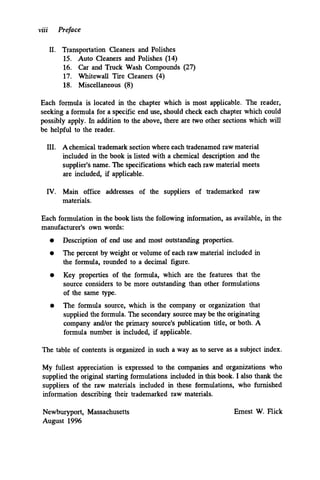

Spray 8 Wipe Type-Aerosol o r Non-Aerosol(1)

Concord Co-Wax Emulsion, 12%

S i 1icone (Union Carbide LE-461)

D i s t i 11ed Water

% by Weiaht

4.1

7.0

88.9

Spray 8 Wipe- Type-Aerosol o r Non-Aerosol(E]

Concord Co-Wax Emulsion, 12%

S i l i c o n e (Union Carbide LE-461)

S i l i c o n e (Union Carbide LE-462)

D i s t i 11ed Water

Weisht

7.5

12.5

2.5

77.5

Spray & Wipe Type-Aerosol o r Non-Aerosol(3)

Concord Co-Wax Emulsion, 12%

S i 1icone (Union Carbide LE-461)

S i l i c o n e (Union Carbide LE-462)

T r i ethanol ami ne Lauryl S u l f a t e

D i s t i 1l e d Water

% by Weiqht

7.5

12.5

2.5

1 . 5

76.0

The formulas l i s t e d above a r e suggested formulas. Every

e f f o r t has been made t o o p t i m i z e a l l p r o p e r t i e s t o get t h e best

p o l i s h w i t h regard t o s p e c i f i c amounts o f i n g r e d i e n t s . Formula #1

i s t h e b e s t a l l around p o l i s h . I t f e a t u r e s e x c e l l e n t gloss,

a p p l i c a t i o n ease and economy. Formula #3 i s an example o f l i g h t

foam-type p o l i s h , and o f f e r s b e t t e r removal o f s o i l and emuls-

i f i c a t i o n o f p r o p e l l e n t s . Formula #2 i l l u s t r a t e s a h i g h g l o s s

formula w i t h e x c e l l e n t p r o t e c t i v e q u a l i t i e s .

L i q u i d Wax-Solvent F u r n i t u r e o r F l o o r P o l i s h

Concord Wax #1600

S i l i c o n e General E l e c t r i c SF 96-100

Safety Solvent (Stoddard Solvent)

% by Weight

6.0

1 .o

93.0

Procedure:

M e l t wax and s i l i c o n e together a t a temperature o f 195-200F

i n one h a l f o f t h e s o l v e n t . The balance o f t h e c o l d s o l v e n t i s

then added t o t h i s s o l u t i o n a f t e r t h e waxes a r e melted.

SOURCE: Concord Chemical Co., I n c . : Suggested Formulations](https://image.slidesharecdn.com/advancedcleaningproductformulations-150102062830-conversion-gate01/85/Advanced-cleaning-product-formulations-Vol-4-148-320.jpg)