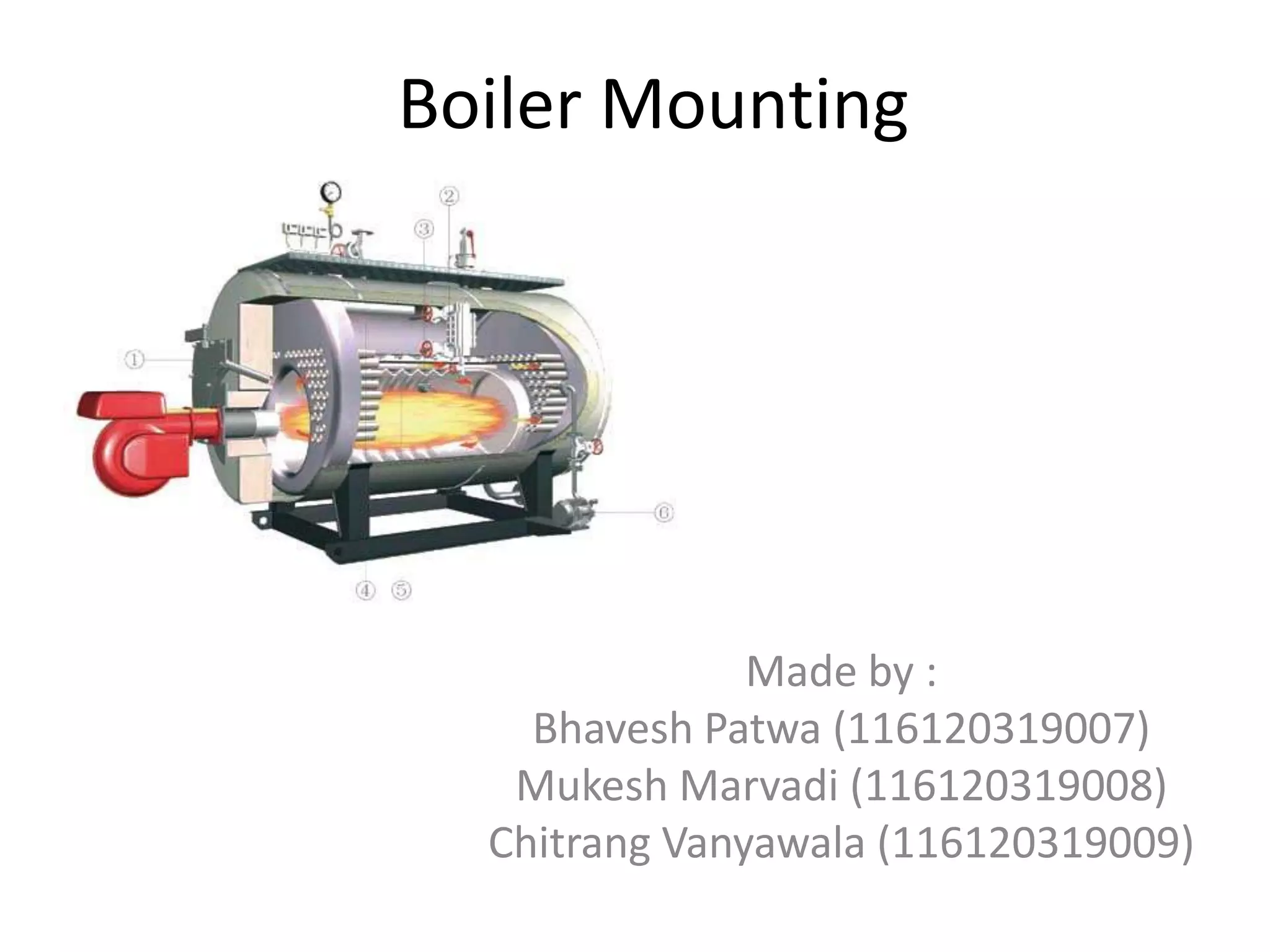

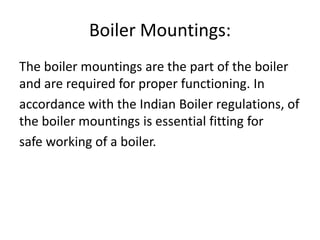

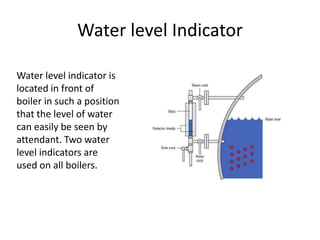

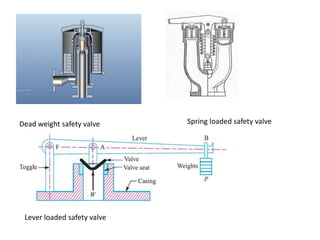

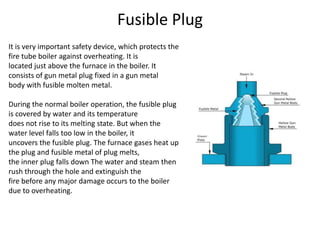

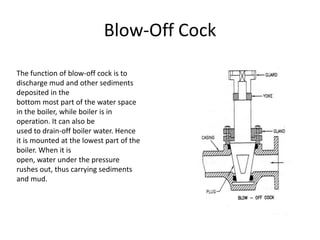

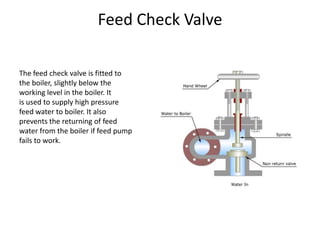

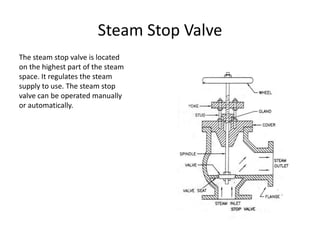

This document summarizes several key boiler mountings including a water level indicator, pressure gauge, safety valves, fusible plug, blow-off cock, feed check valve, and steam stop valve. The water level indicator and pressure gauge monitor water levels and steam pressure. Safety valves include dead weight, spring loaded, and lever loaded types to prevent overpressure. A fusible plug protects against overheating by melting when exposed. The blow-off cock removes sediment while the feed check valve supplies water and the steam stop valve regulates steam supply. All of these mountings are essential for safe operation of the boiler according to Indian Boiler regulations.