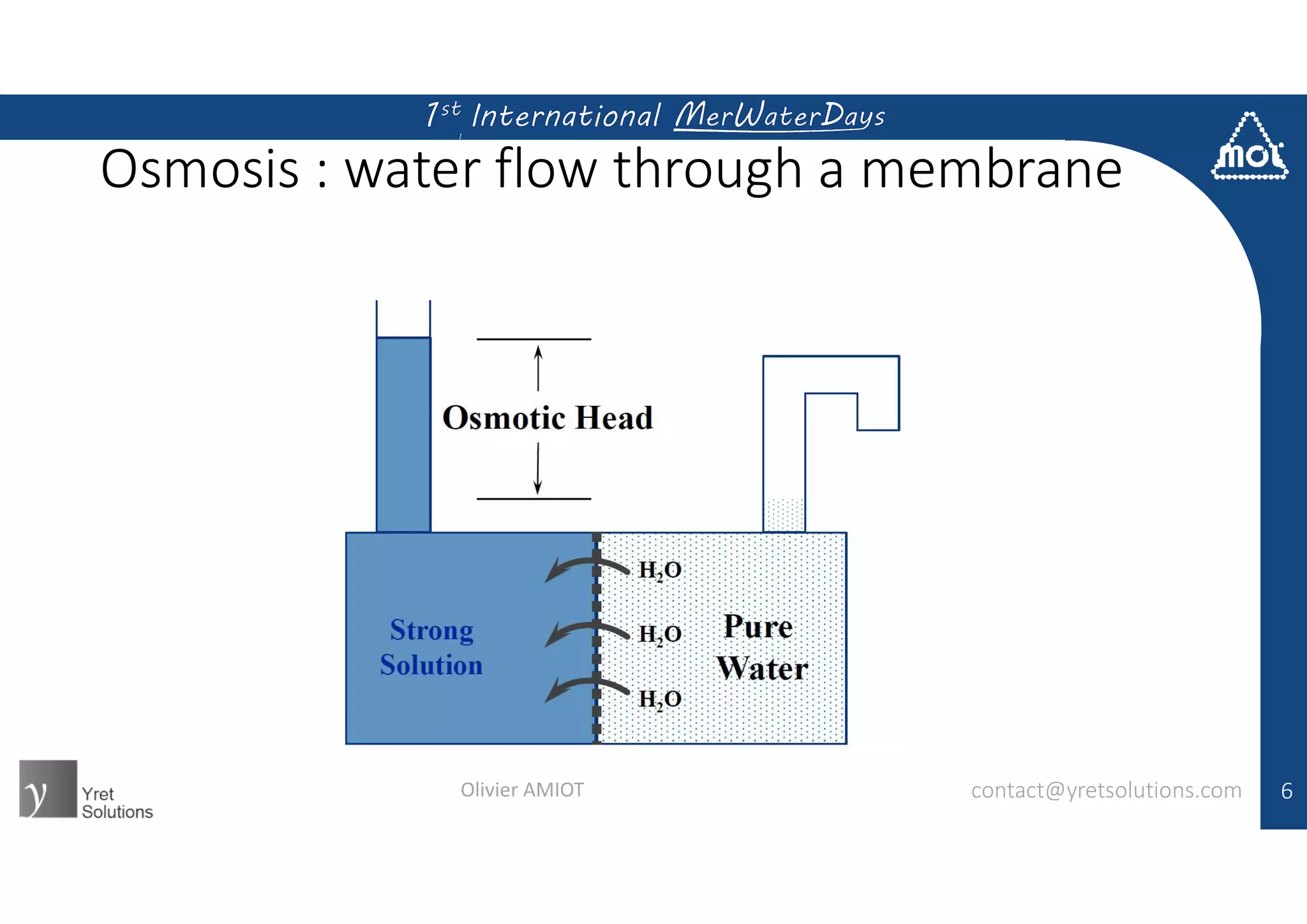

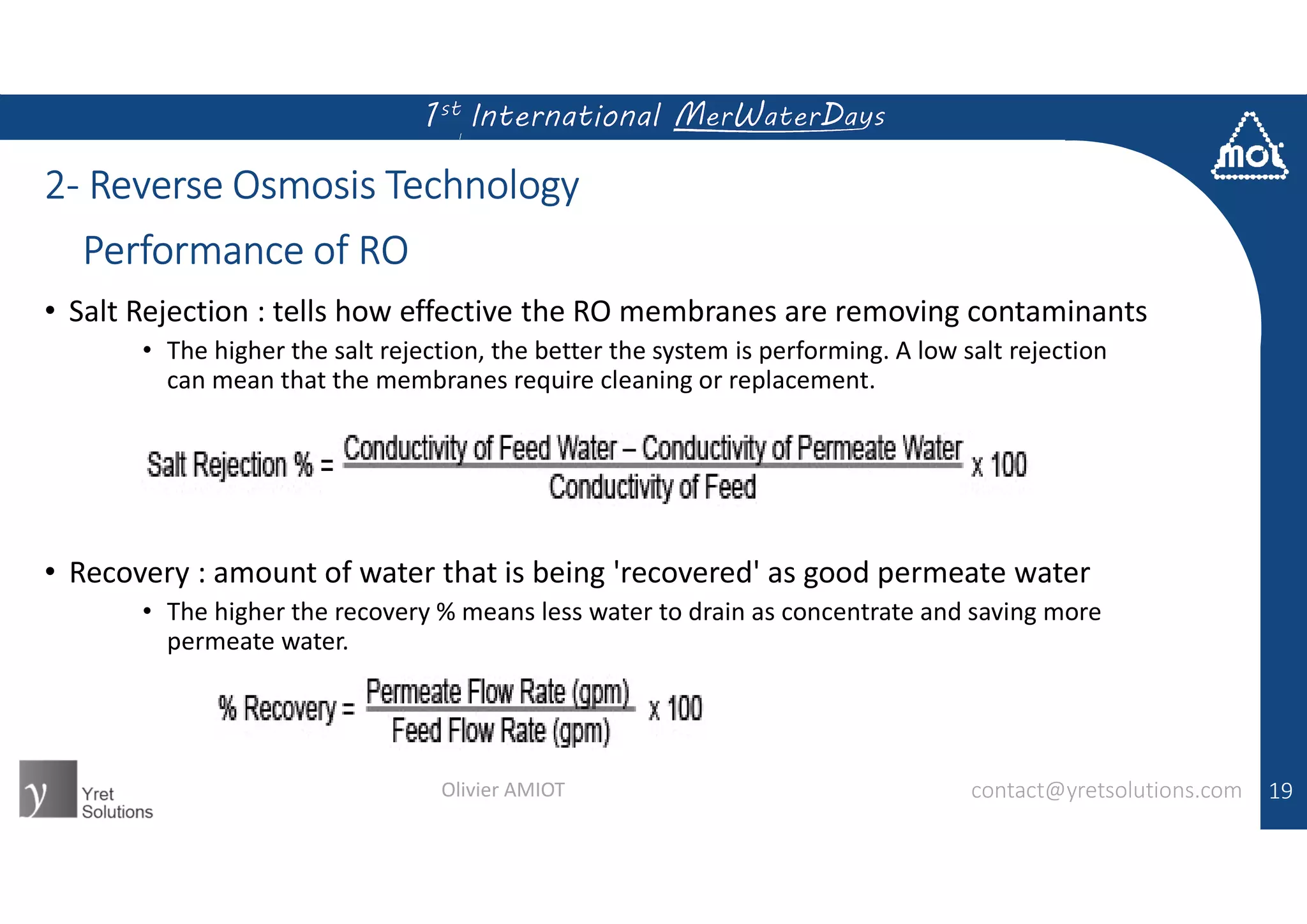

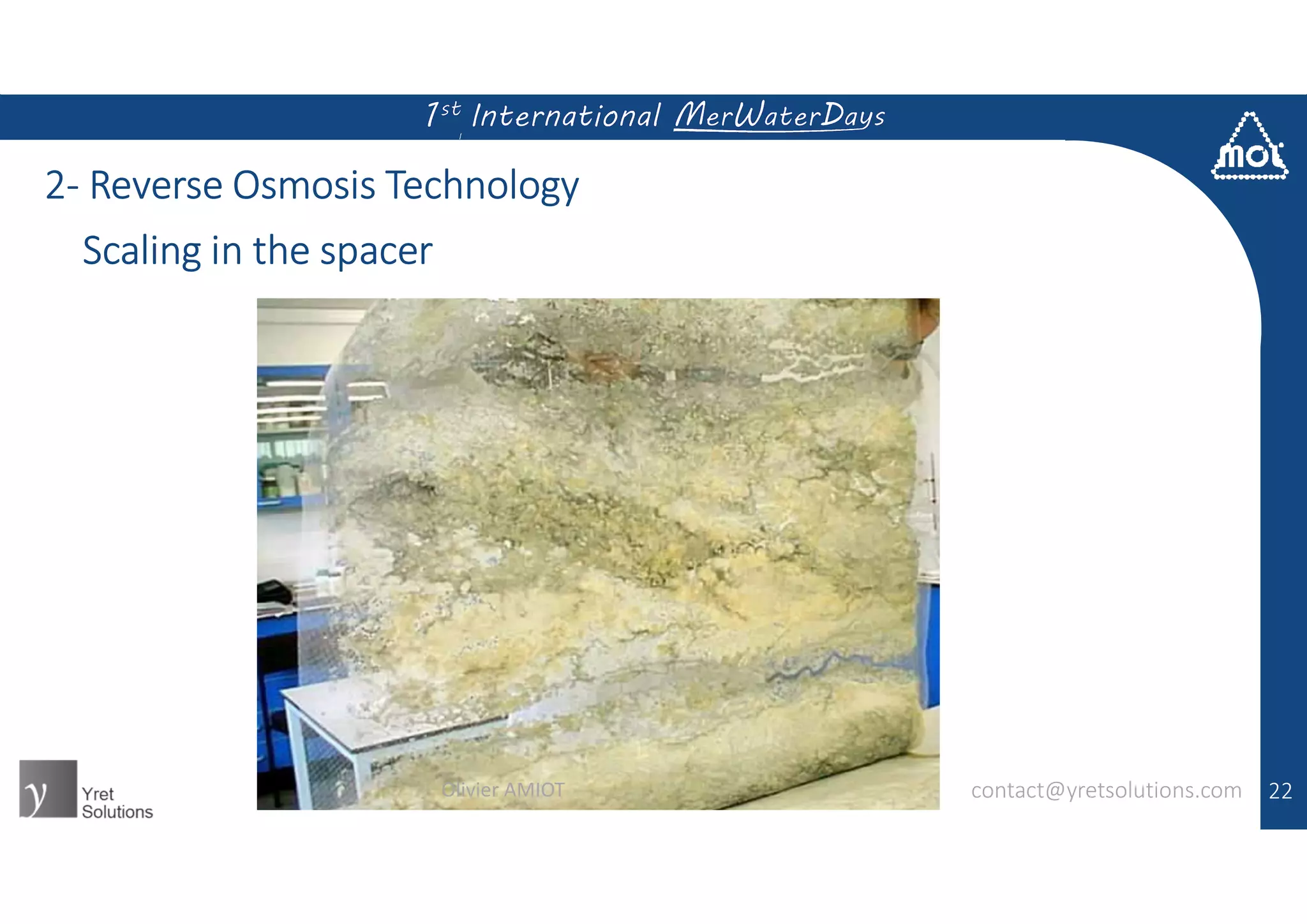

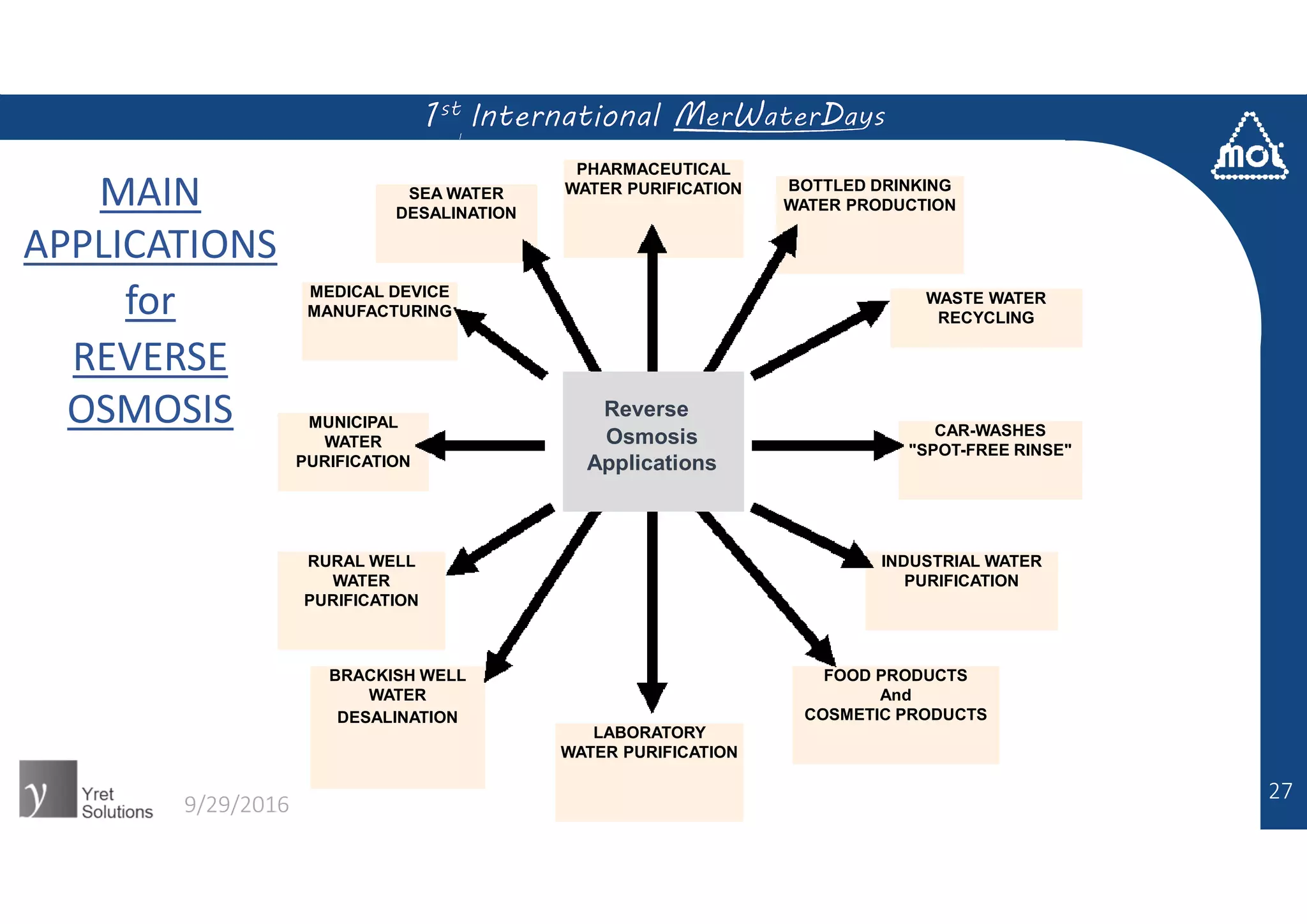

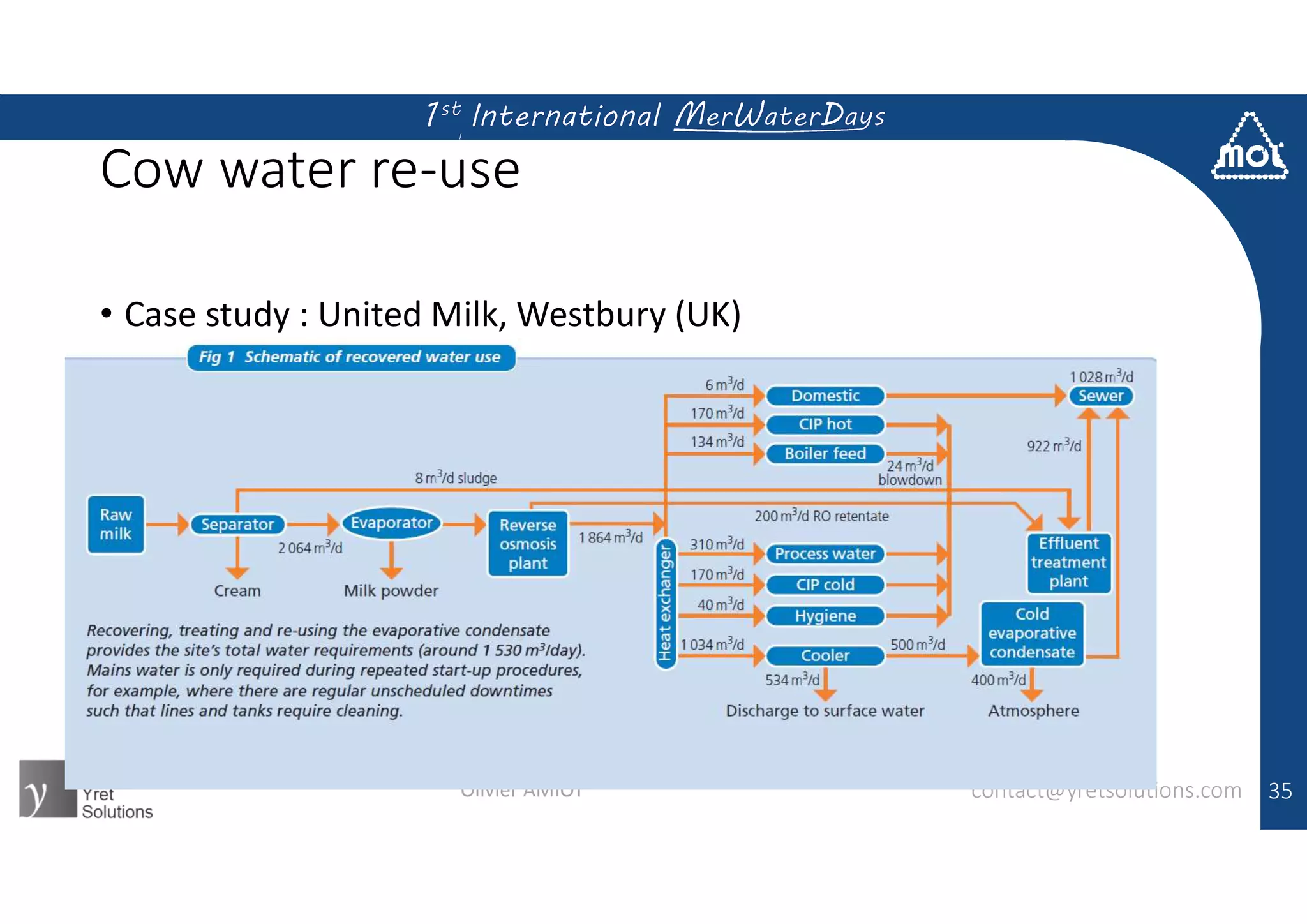

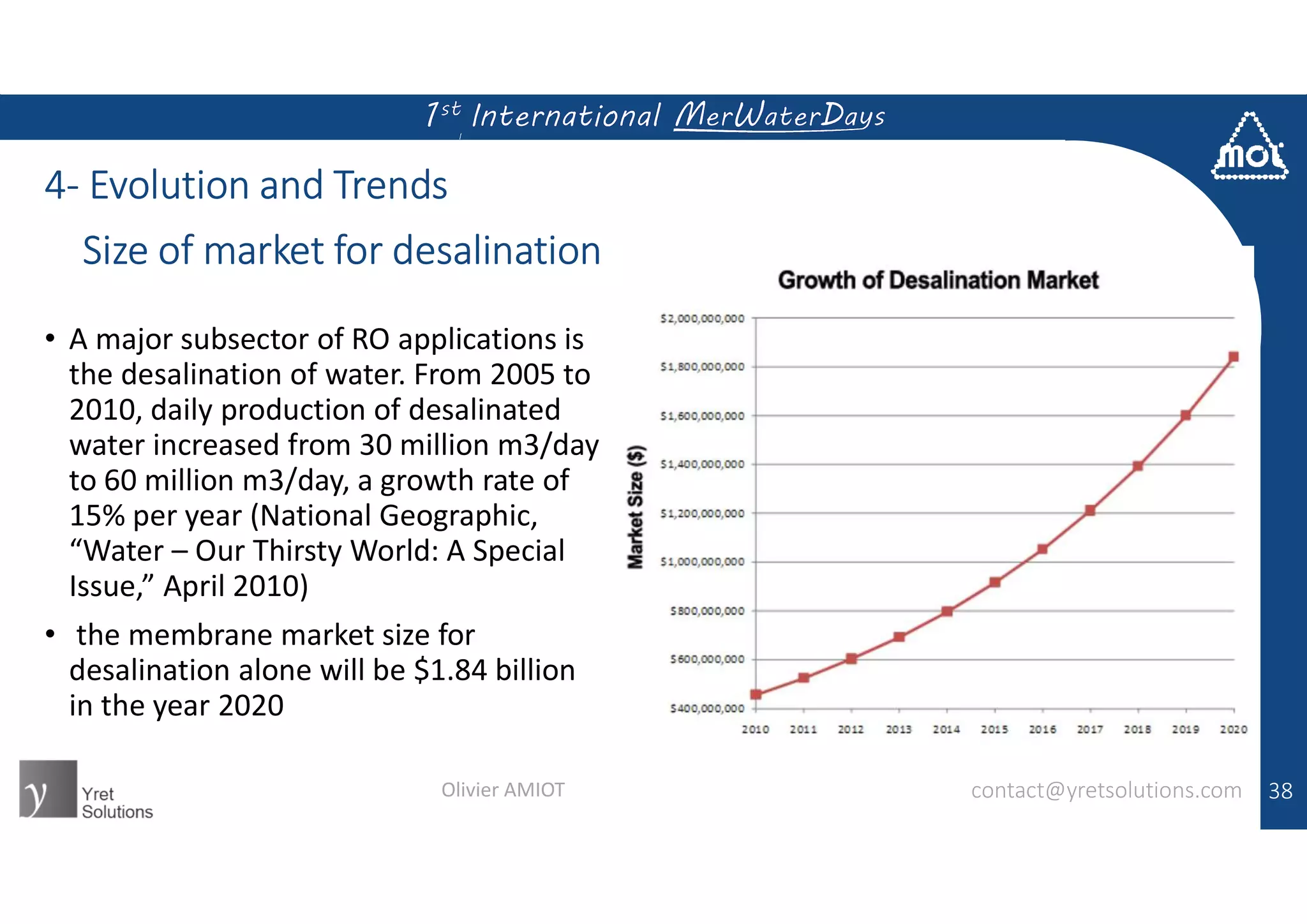

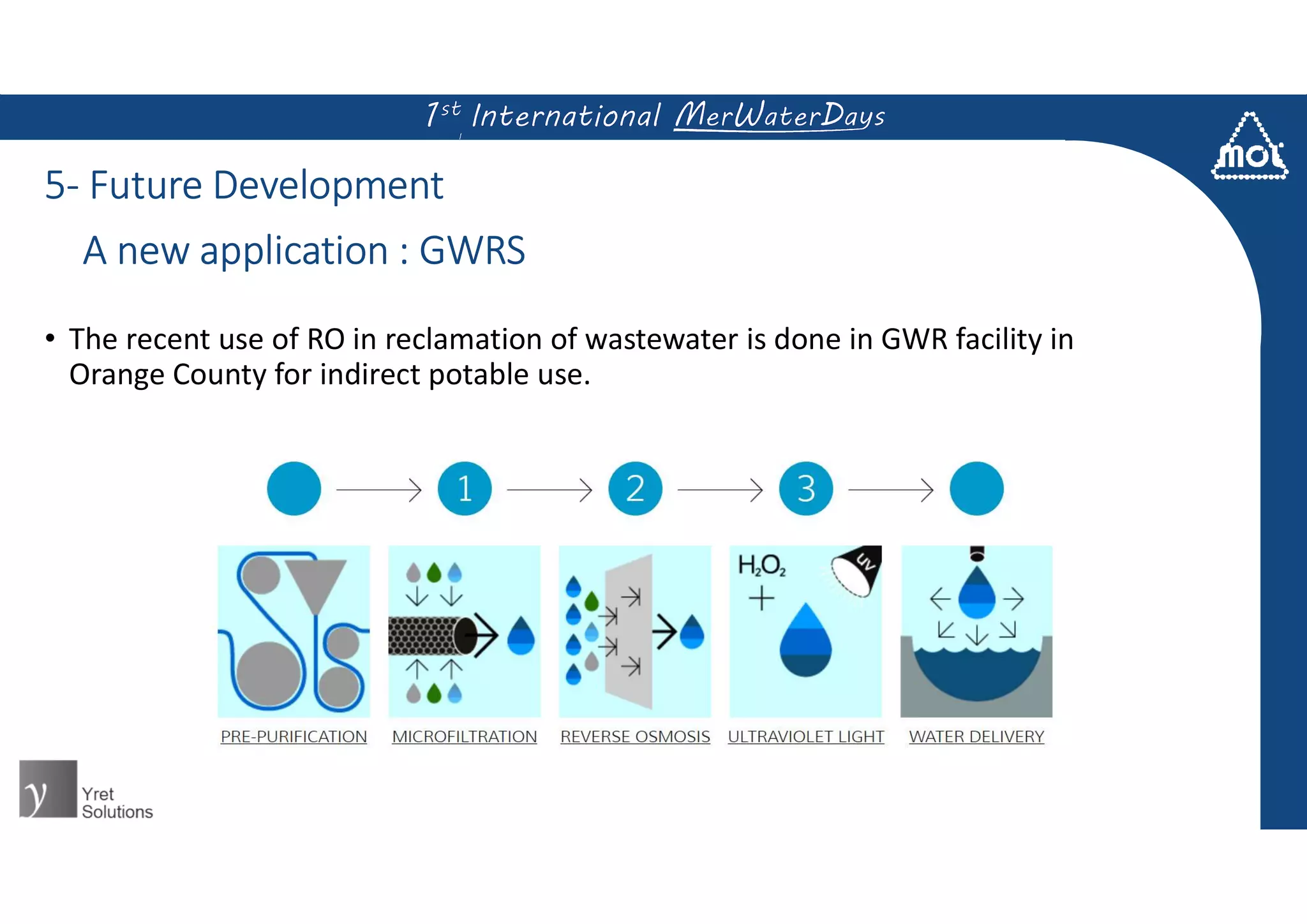

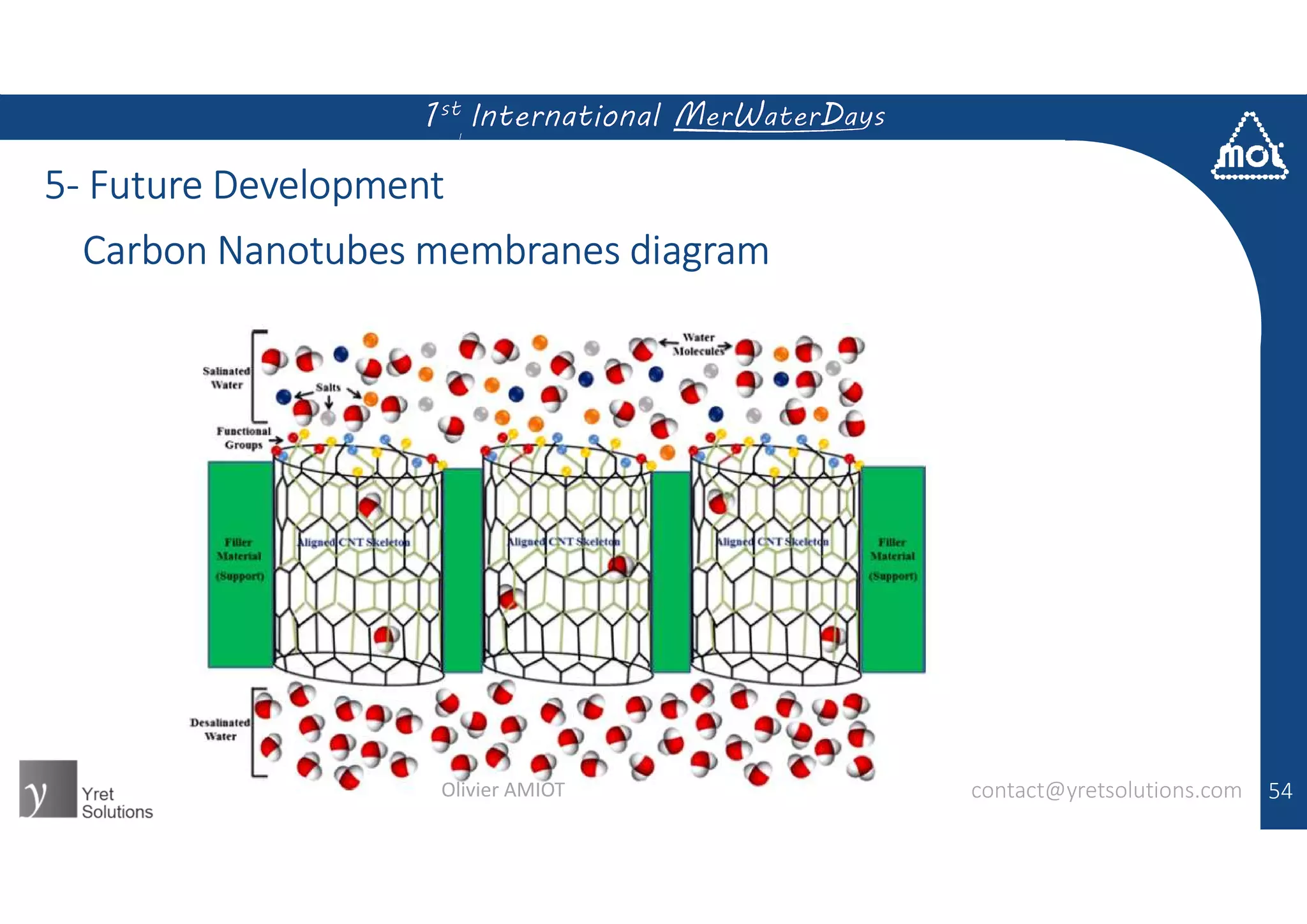

The document provides a comprehensive overview of reverse osmosis (RO), explaining its history, technical workings, market applications, and future trends. Key points include the evolution of RO technology, its use in water purification for various industries, and advancements such as carbon nanotube membranes. It emphasizes the importance of RO in addressing global water challenges, particularly in desalination and wastewater recycling.