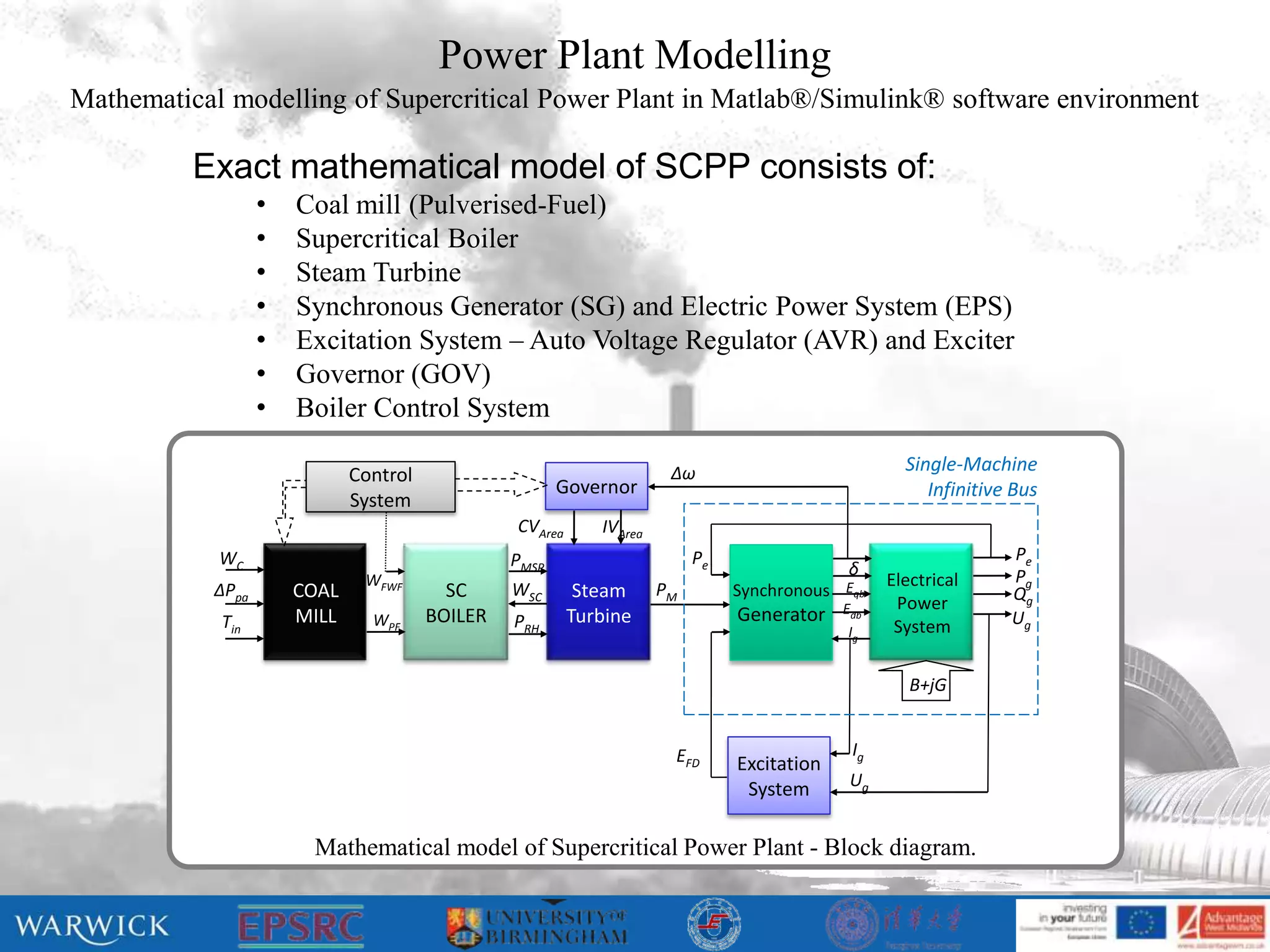

This document provides an overview of a workshop on mathematical modelling and simulation of power plants and CO2 capture. [1] It discusses modelling of supercritical coal-fired power plants, including models of the coal mill, supercritical boiler, steam turbine, and synchronous generator. [2] The models are implemented in MATLAB/Simulink and include differential equations representing the various components. [3] The workshop aims to understand the dynamic responses of supercritical power plants and investigate strategies to improve their ability to respond quickly to changes in electricity demand as required by grid codes.

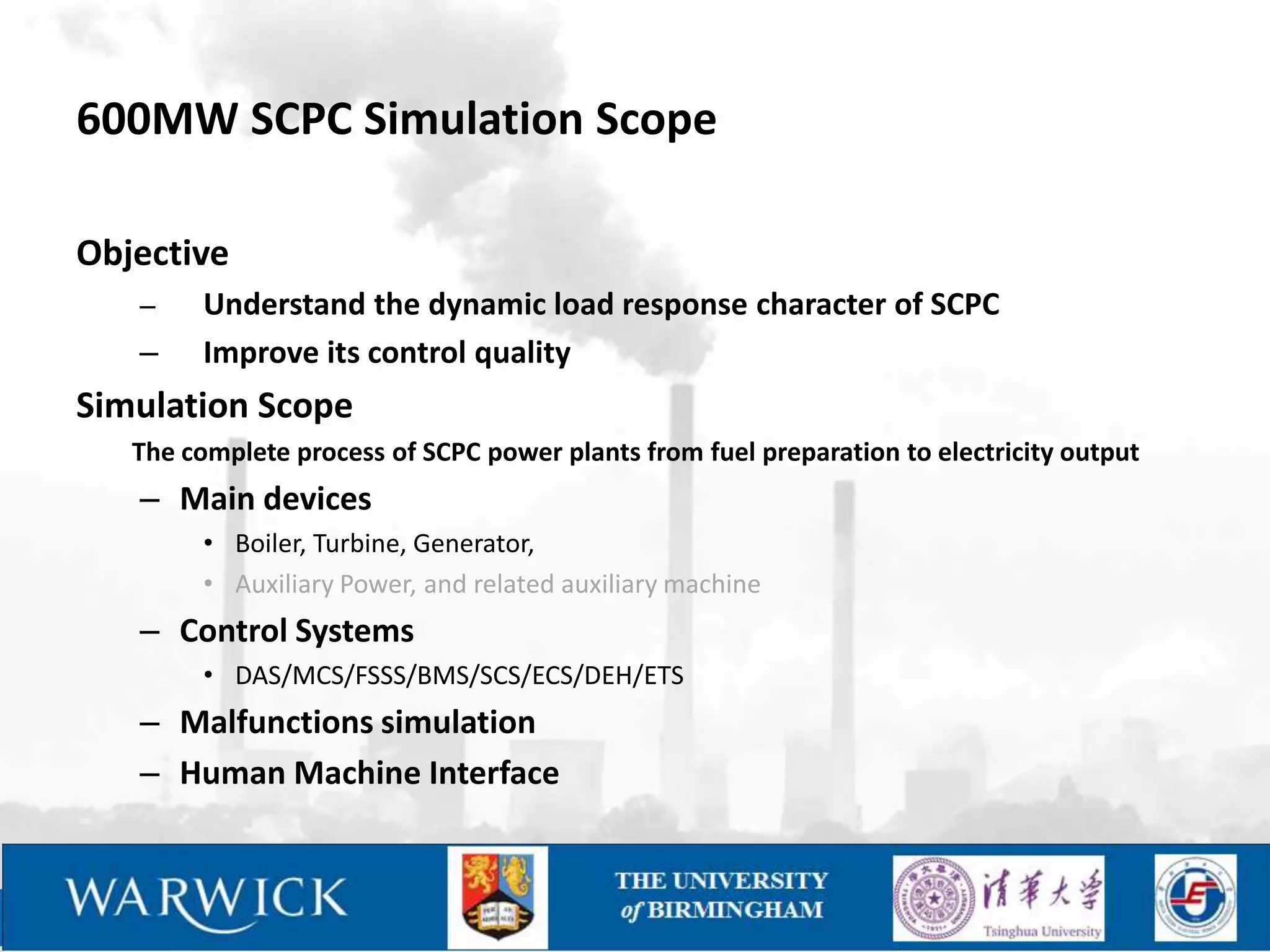

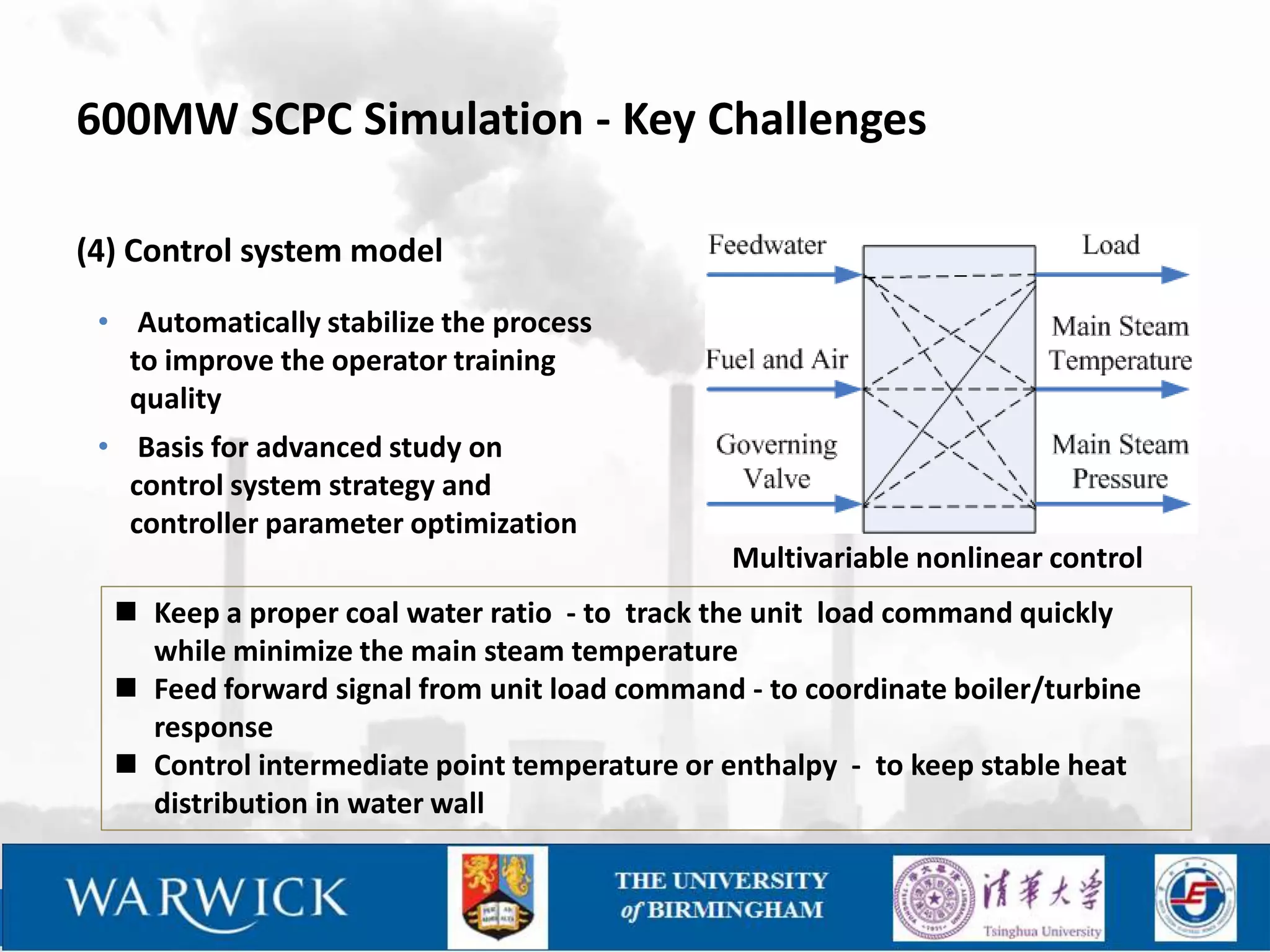

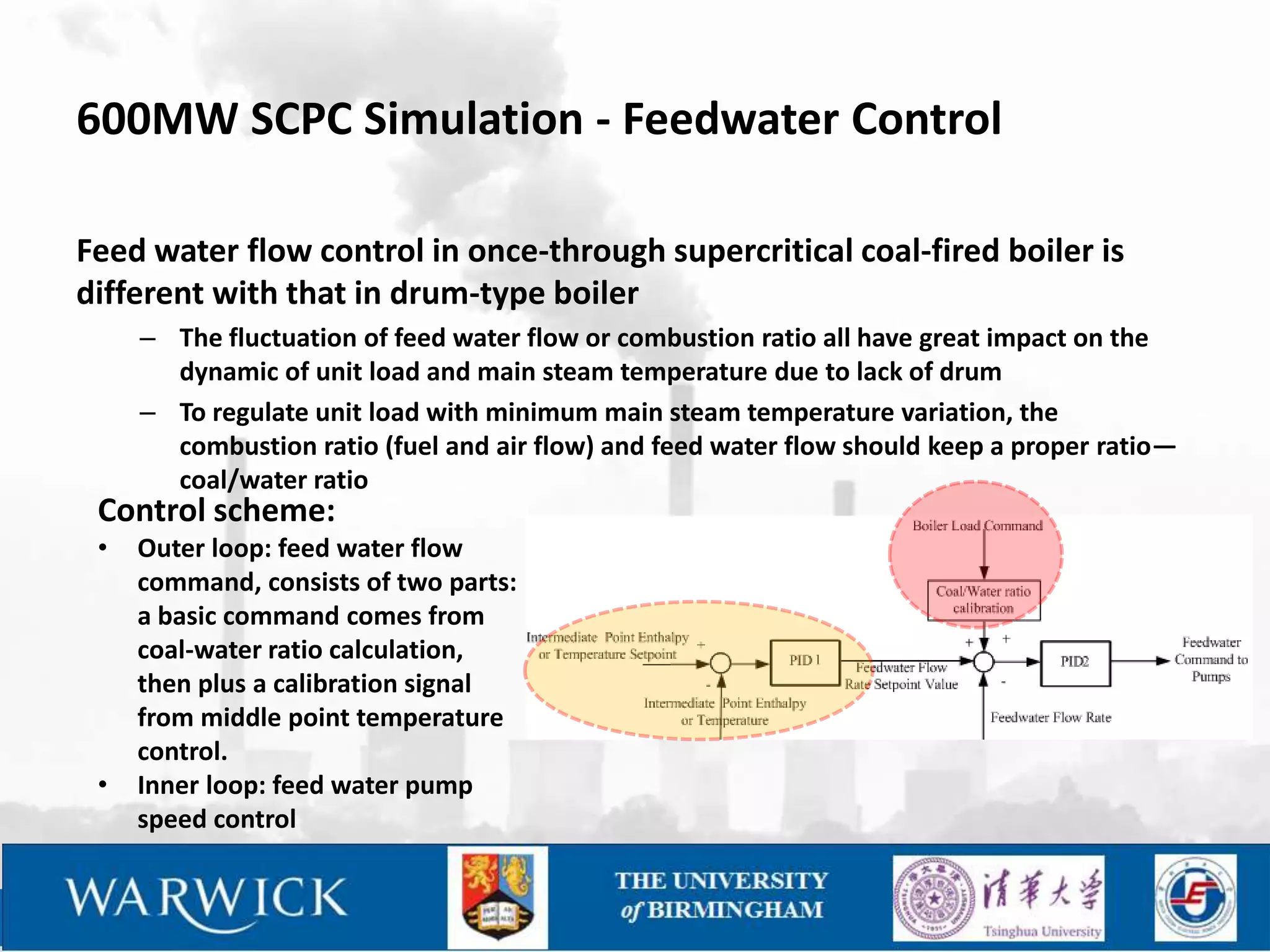

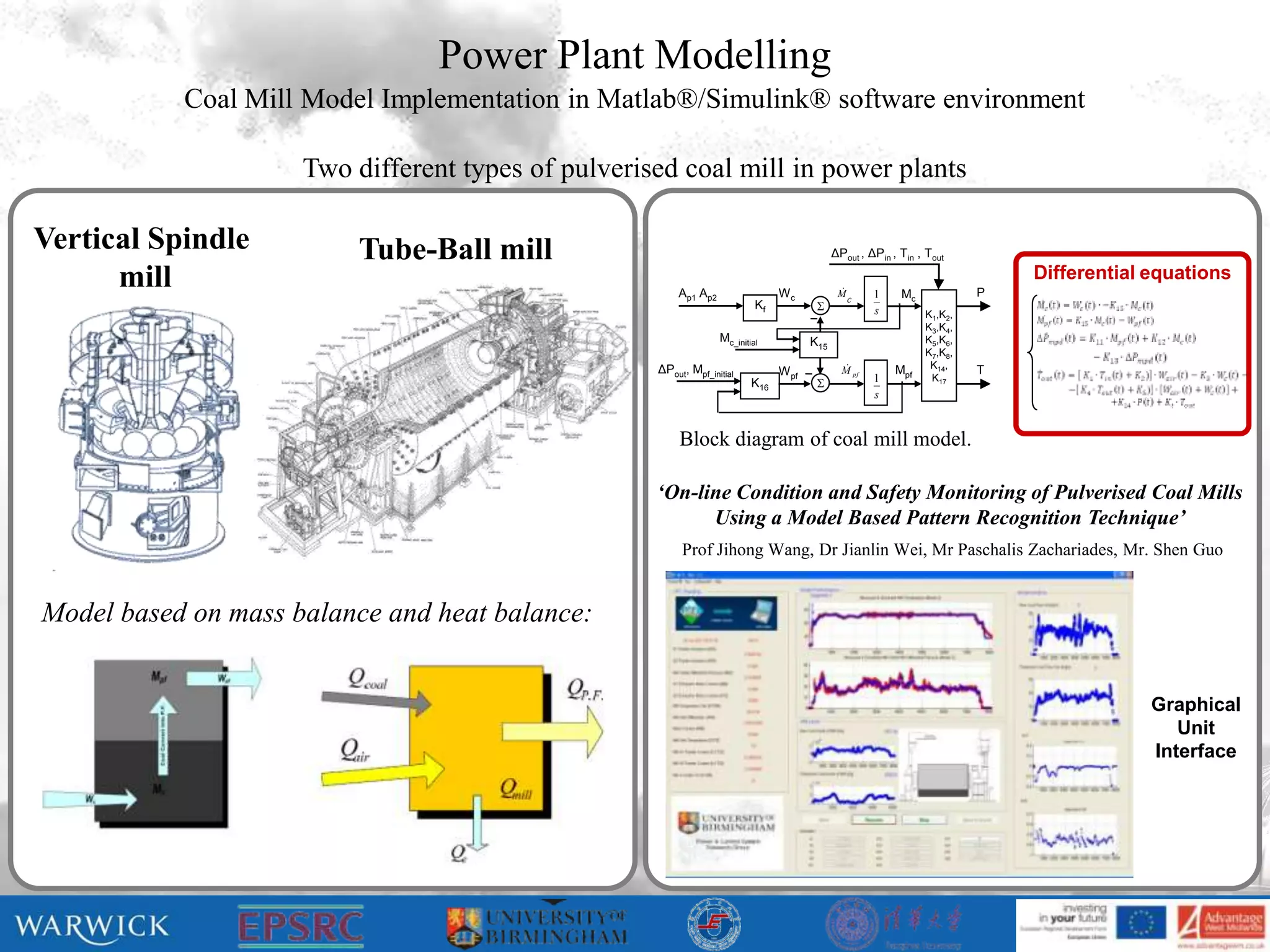

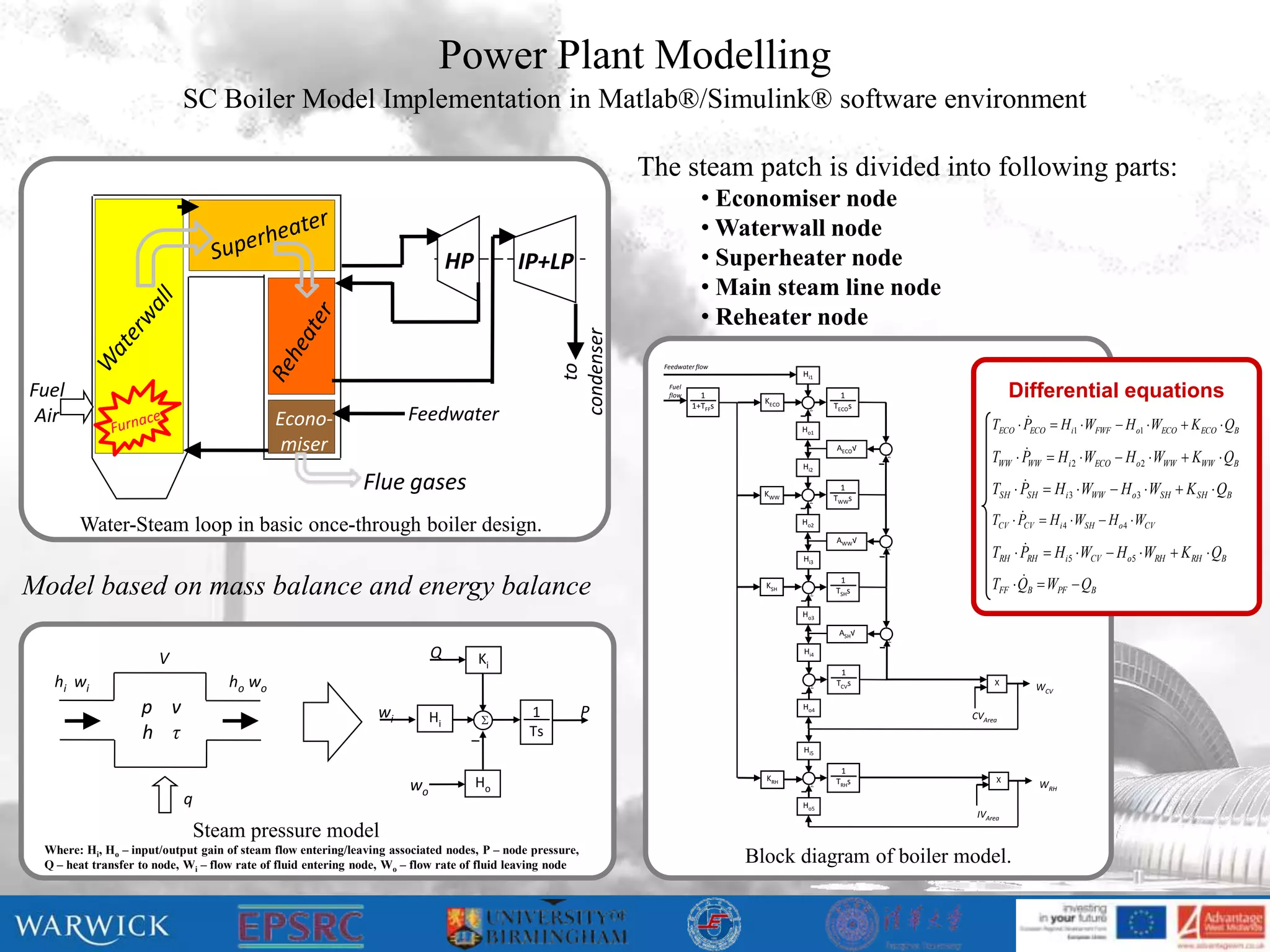

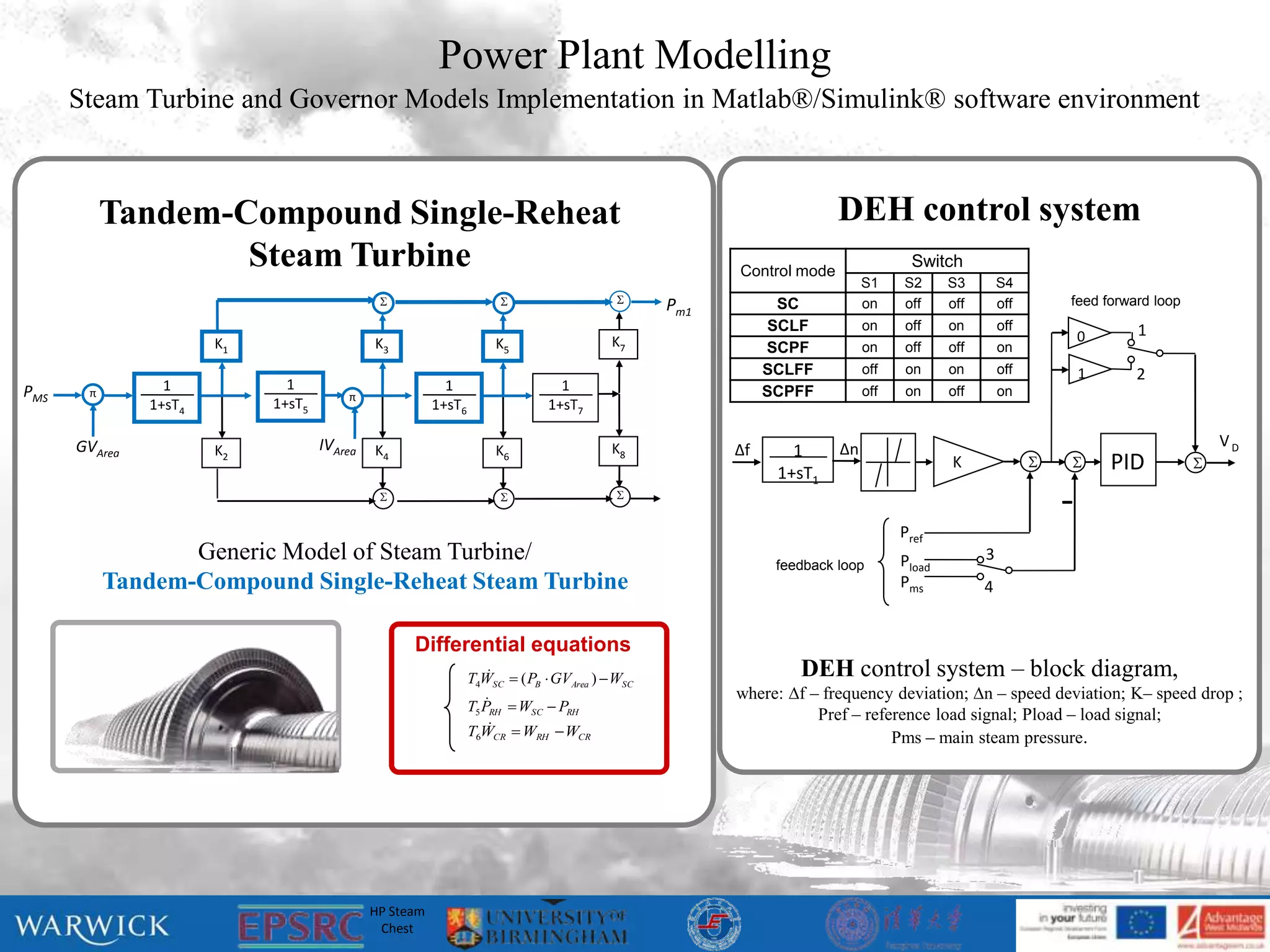

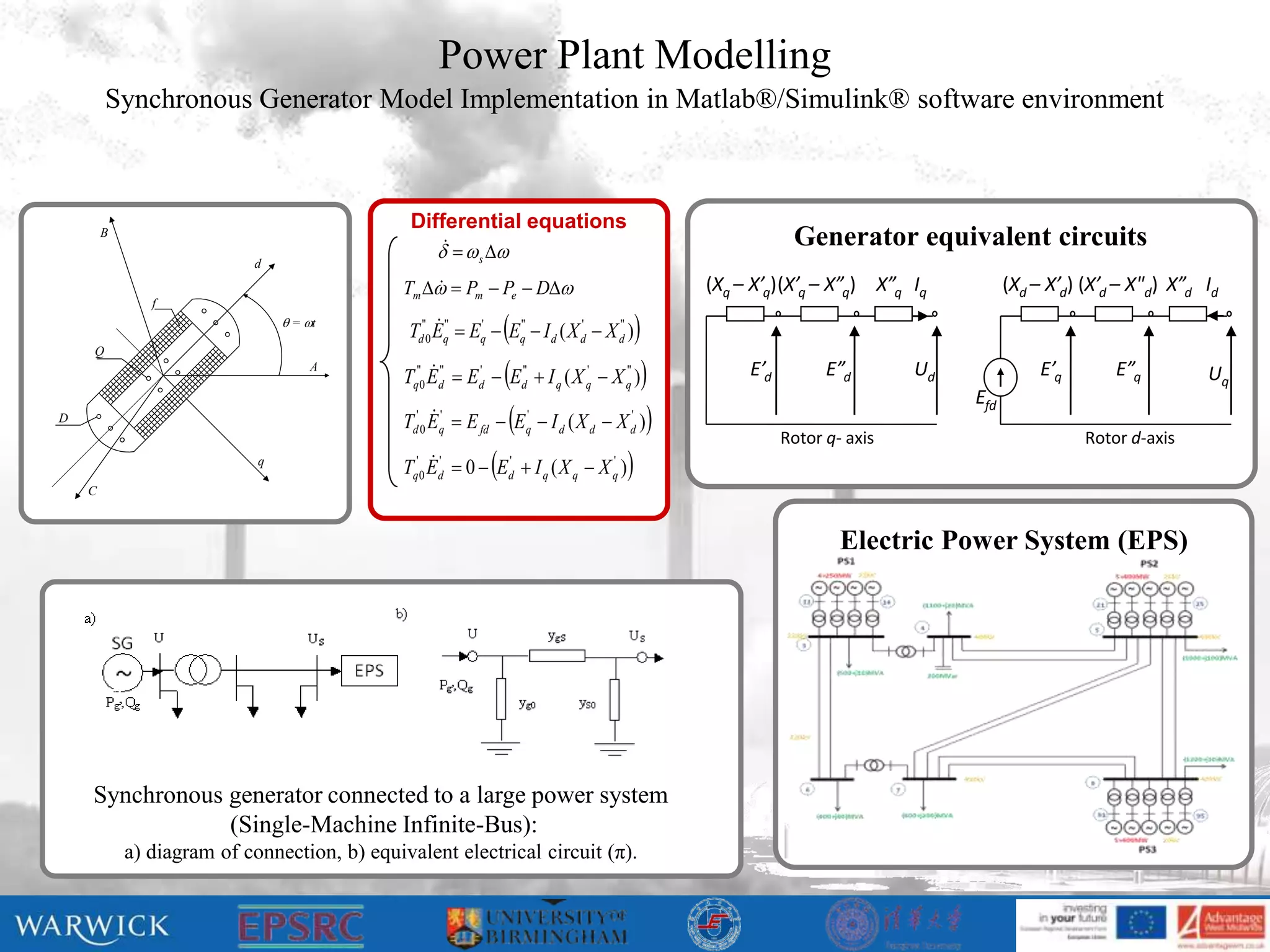

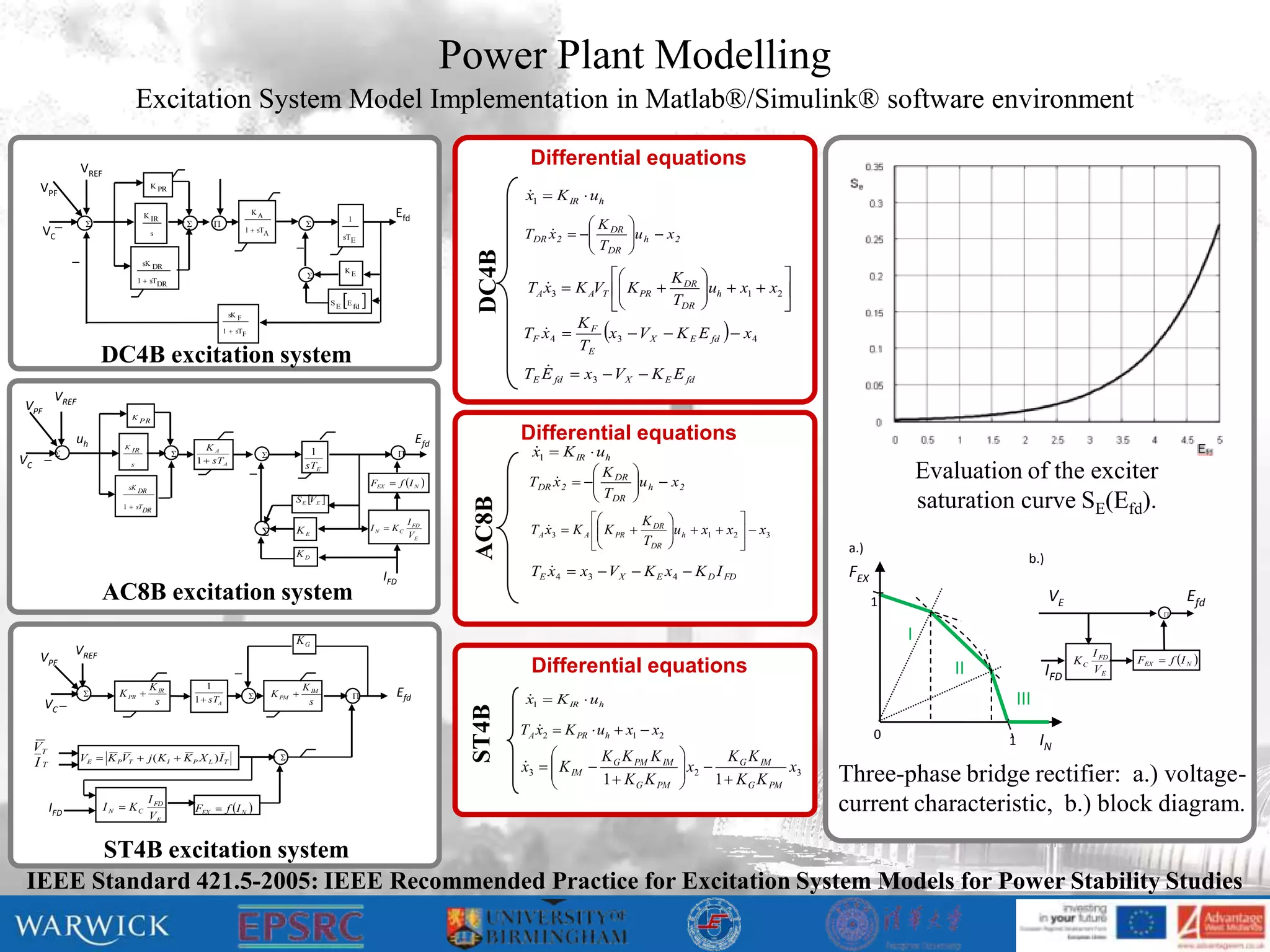

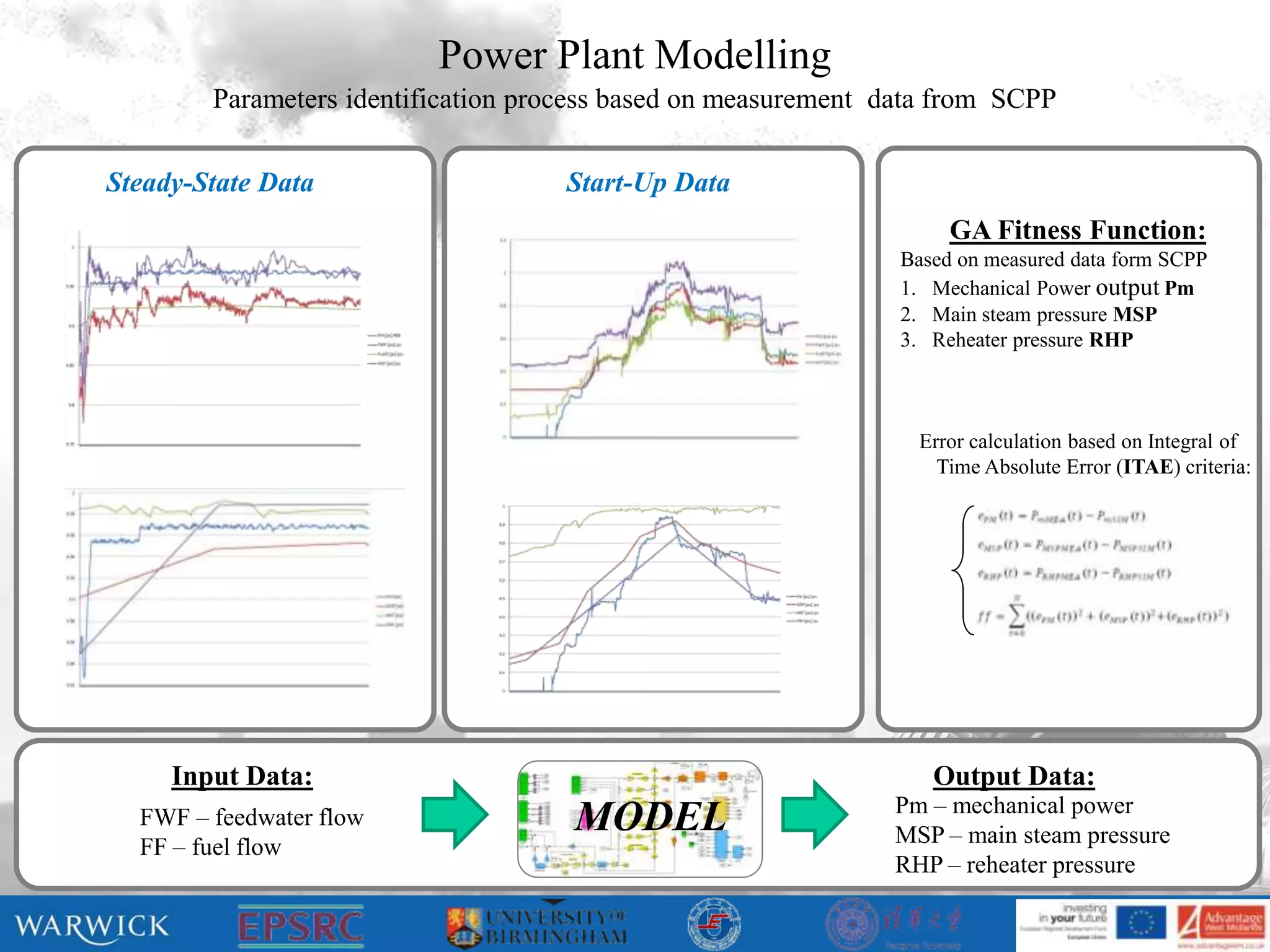

![UK Power System

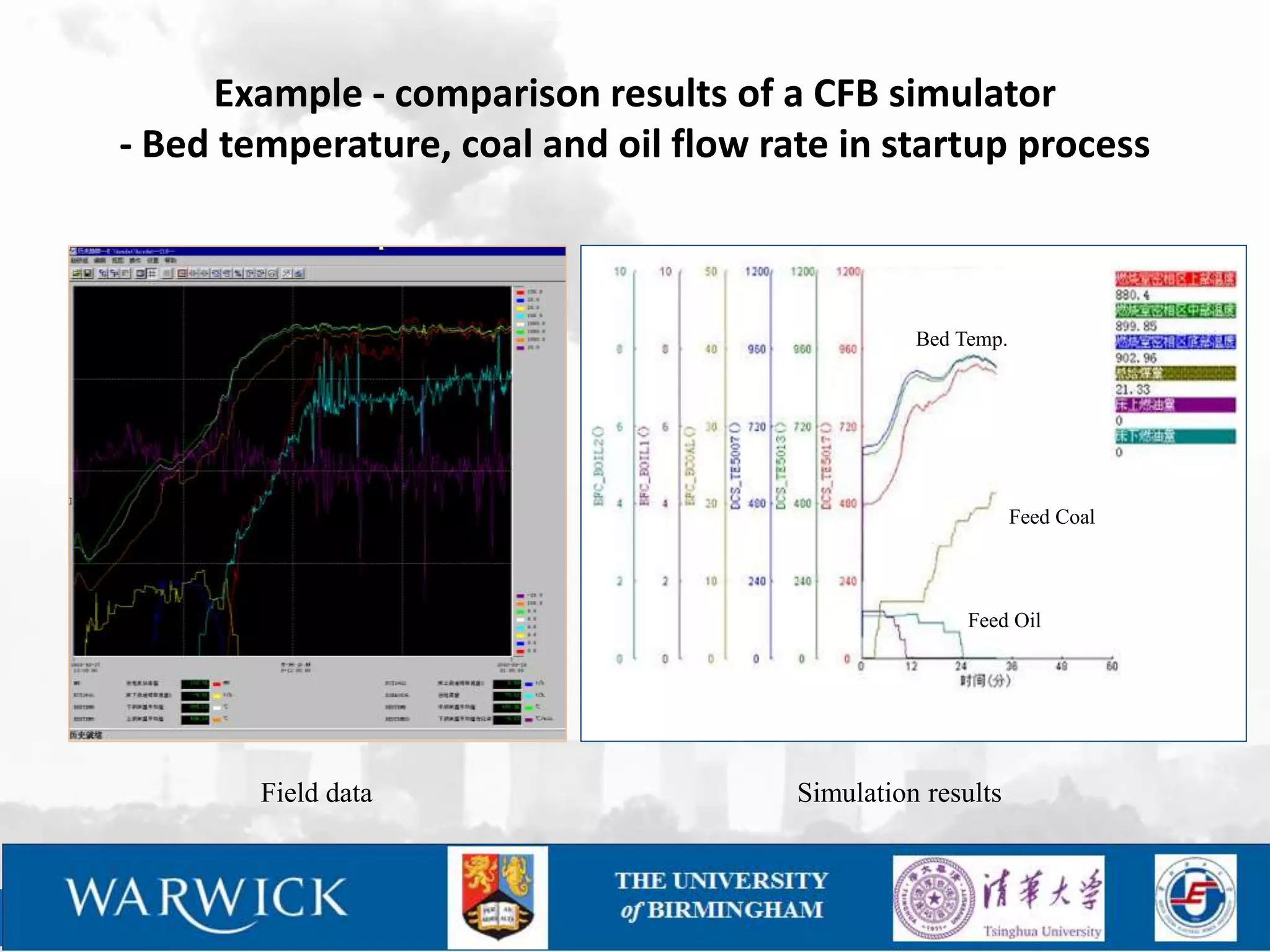

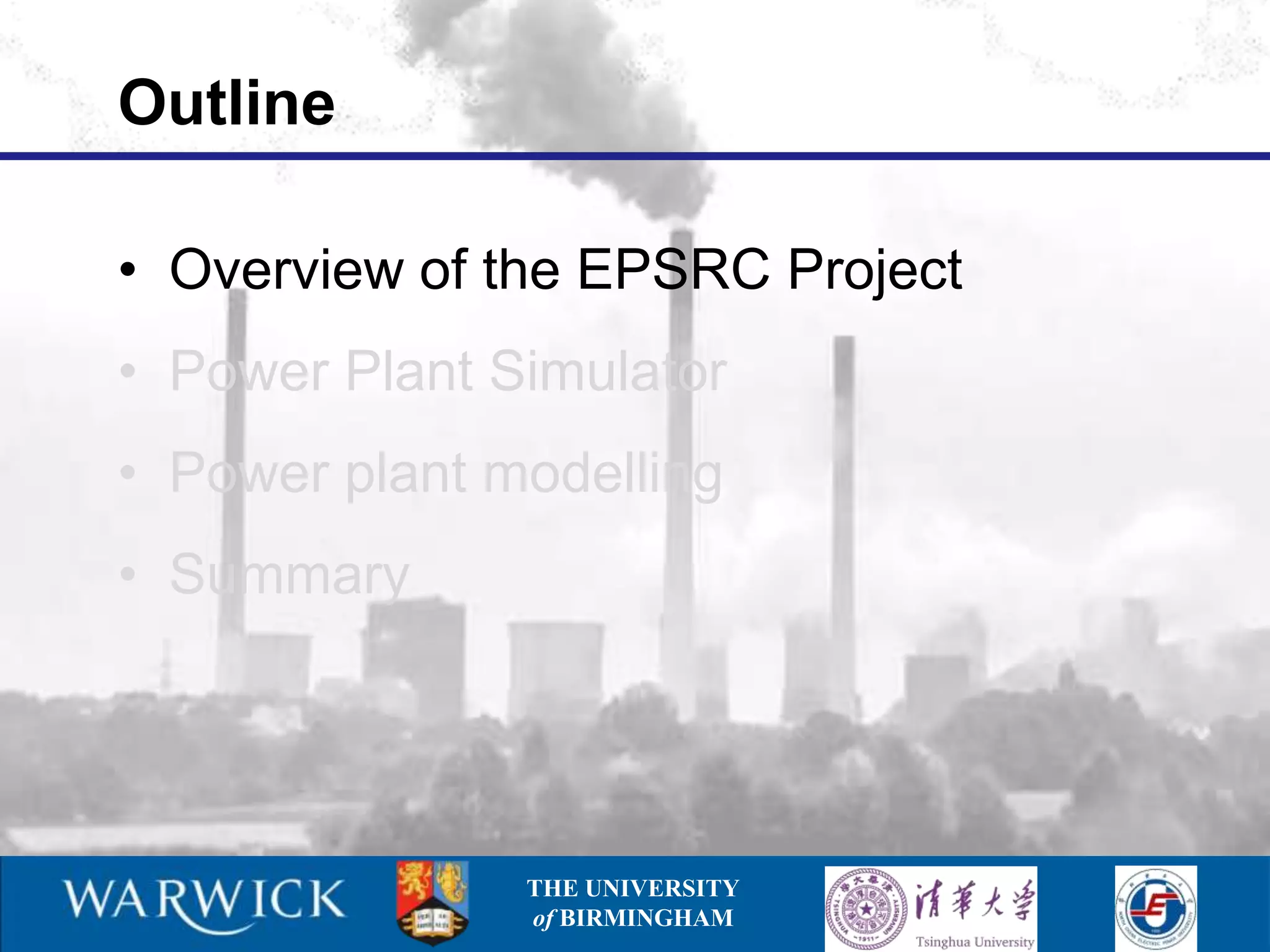

Electricity Supplied by Fuel Type in 2010:

Transmission System Operators (TSOs):

• National Grid

• Scottish and Southern Energy

• Scottish Power

System Data:

Circuit Voltage Circuit Length

TSO

[kV] [km]

National Grid 400, 275 ~14,000

Scottish and

275, 132 ~5,000

Southern Energy

Scottish Power 400, 275, 132 ~4,000

THE UNIVERSITY

of BIRMINGHAM](https://image.slidesharecdn.com/wang-130324234524-phpapp01/75/Wang-Workshop-on-Modelling-and-Simulation-of-Coal-fired-Power-Generation-and-CCS-Process-12-2048.jpg)

![UK Power System — The Grid Code —

Nominal Frequency: 50 Hz

Frequency Variation Interval [Hz]

Normal

Critical Situations

Operation

49.5 – 50.5 47.0 – 52.0

Frequency Control Strategies

Type of Frequency Control

Response Time

Strategy

active power increase within 10 s and

Primary Frequency Response

maintained for another 30 s

active power increase within 30 s and

Secondary Frequency Response

maintained for another 30 min

active power decrease within 10 s and

High Frequency Response

maintained thereafter

THE UNIVERSITY

of BIRMINGHAM](https://image.slidesharecdn.com/wang-130324234524-phpapp01/75/Wang-Workshop-on-Modelling-and-Simulation-of-Coal-fired-Power-Generation-and-CCS-Process-13-2048.jpg)

![Power Plant Modelling

Model Parameters identification process in Matlab®/Simulink®

Model = structure + parameters

Integrating the intelligent optimisation algorithms with the power plant

model for parameters identification

Plant measurement

DATA from

SC Power Plant

Data input to model

Simulated and

MATLAB® Parameters SIMULINK®

measured

Genetic update Simulation Stopping YES

outputs Model

Algorithm for new criterion

parameters

Parameters

[Toolbox] met

(+measurement ?

input DATA)

NO](https://image.slidesharecdn.com/wang-130324234524-phpapp01/75/Wang-Workshop-on-Modelling-and-Simulation-of-Coal-fired-Power-Generation-and-CCS-Process-22-2048.jpg)

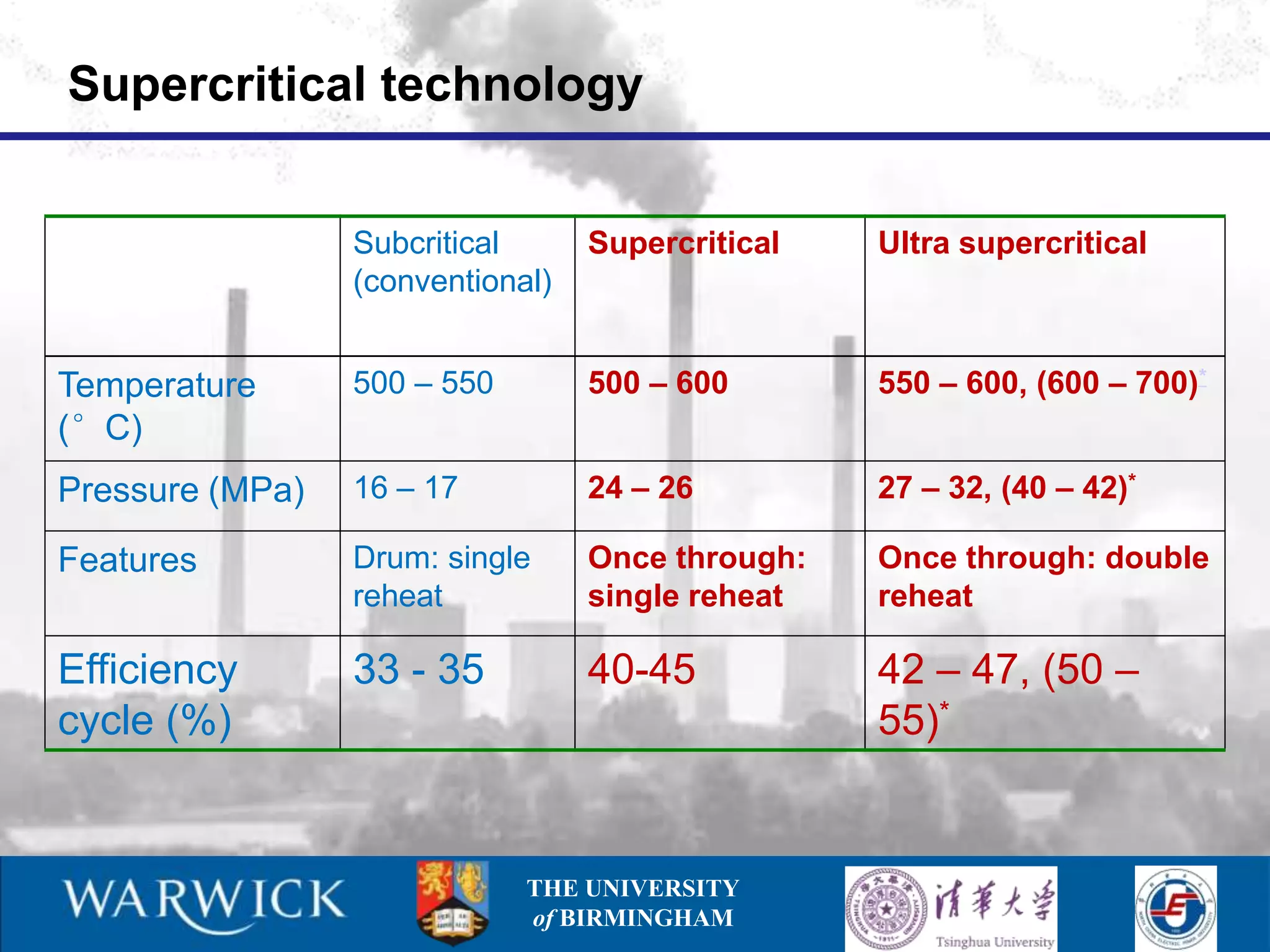

![Power Plant Modelling

Model Parameters Verification – Results for the best parameters set

0.9

0.8

PM [pu]

0.7 Pm – mechanical power

000

0.6

0.5

0.4

0.3

2000 4000 6000 8000 10000 12000 14000

t [s]

1

0.9

MSP [pu]

0.8

0.7 00

MSP – main steam pressure

0.6

0.5

0.4

2000 4000 6000 8000 10000 12000 14000

t [s]

0.8

RHP [pu]

0.7

00

RHP – reheater pressure

0.6

0.5

0.4

data from industry

0.3

2000 4000 6000 8000 10000 12000 14000 Simulink model

t [s]](https://image.slidesharecdn.com/wang-130324234524-phpapp01/75/Wang-Workshop-on-Modelling-and-Simulation-of-Coal-fired-Power-Generation-and-CCS-Process-24-2048.jpg)