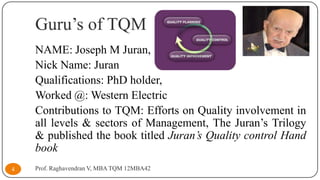

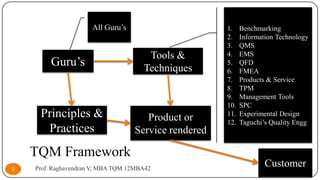

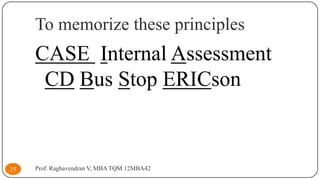

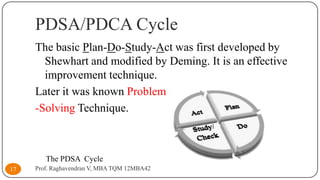

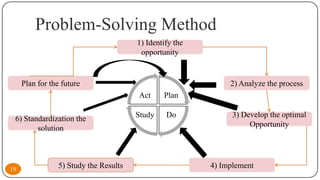

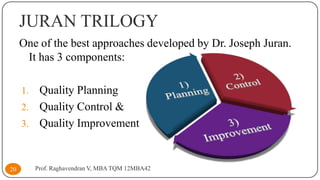

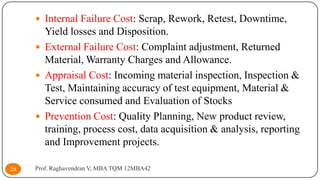

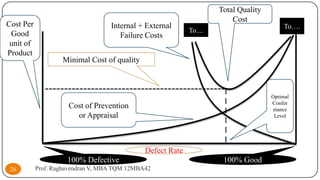

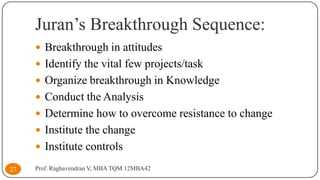

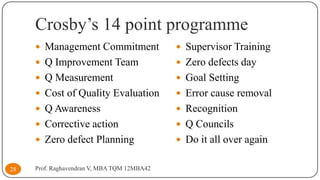

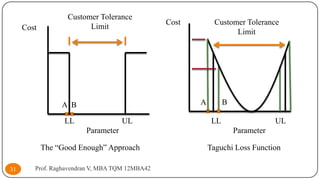

The document discusses the key contributors to Total Quality Management (TQM). It profiles 8 quality gurus: Walter Shewhart, W. Edwards Deming, Joseph Juran, Armand Feigenbaum, Kaoru Ishikawa, Philip Crosby, Genichi Taguchi, and their major contributions to developing TQM principles and techniques. Their works involved developing concepts like control charts, Deming's 14 principles, Juran's trilogy, quality costs, PDCA cycle, loss functions, and quality circles that formed the basis of modern quality management approaches.