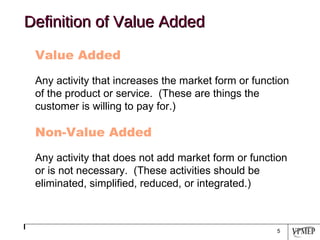

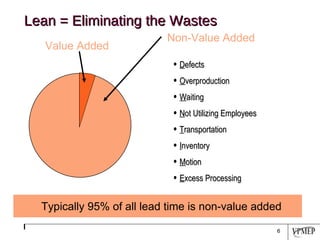

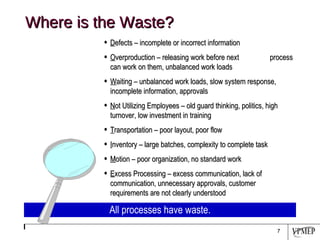

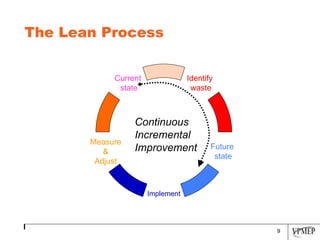

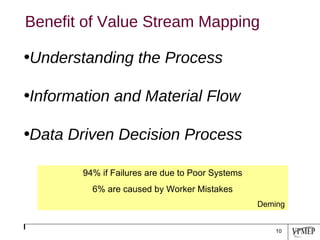

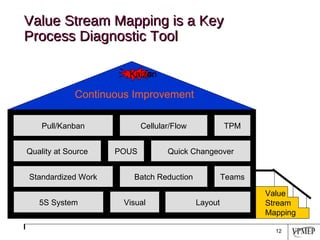

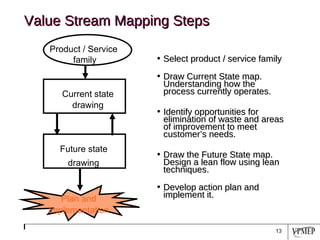

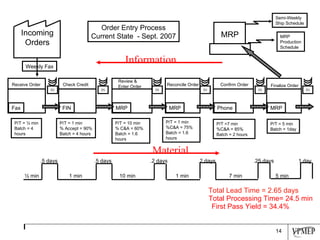

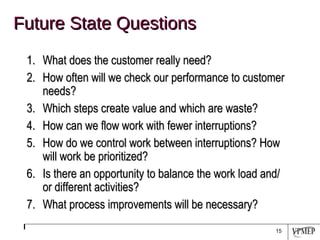

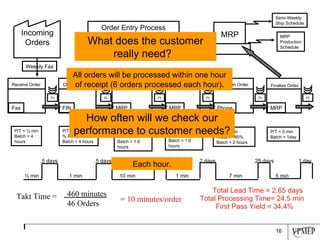

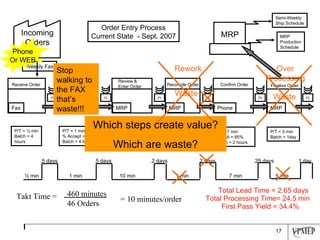

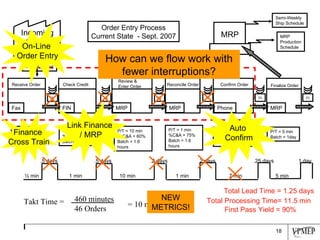

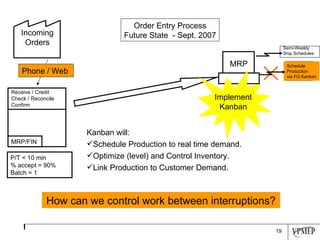

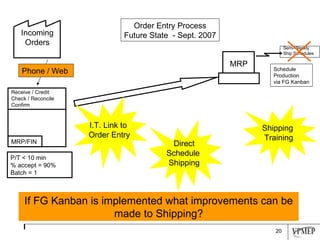

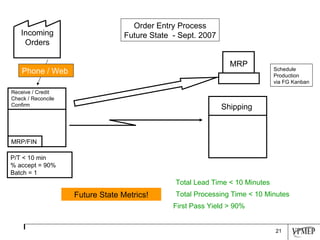

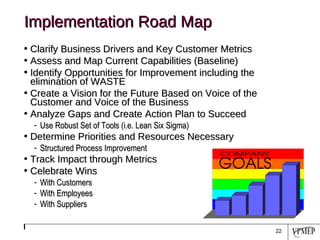

Value stream mapping is a technique to identify and eliminate waste in business processes. It involves mapping the current state of a process, identifying non-value added activities (waste), designing a future state with less waste, and implementing improvements. The document discusses how value stream mapping was used to redesign an order entry process, reducing lead time from 2.65 to less than 1 day by streamlining steps, improving flow, and implementing techniques like kanban to control workflow. It emphasizes that all processes contain waste and continuous improvement requires understanding processes and change.