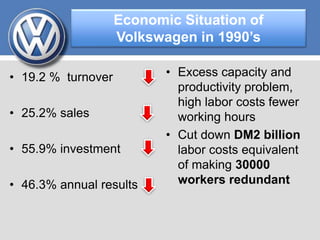

- Volkswagen was facing economic problems in the 1990s including high costs, excess capacity, and productivity issues.

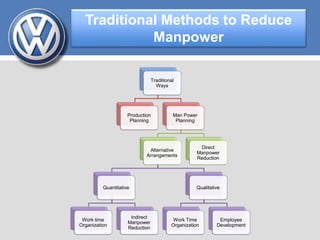

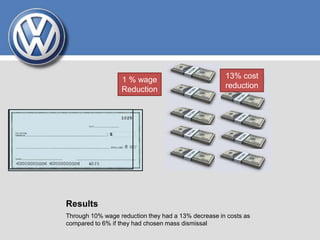

- Traditional methods to reduce labor costs, such as mass layoffs, would result in only a 6% reduction in costs.

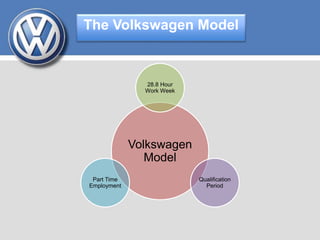

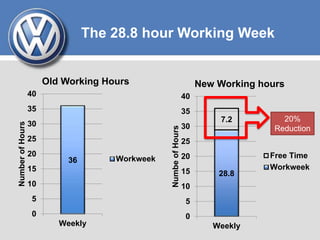

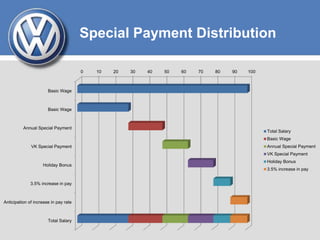

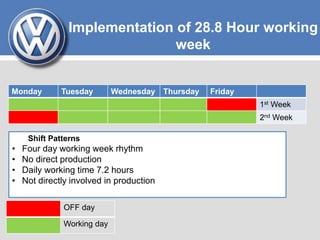

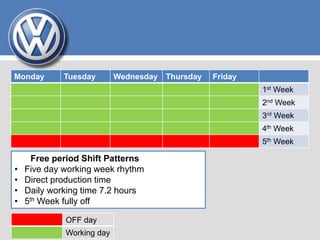

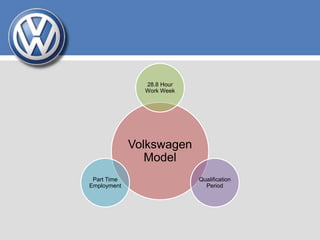

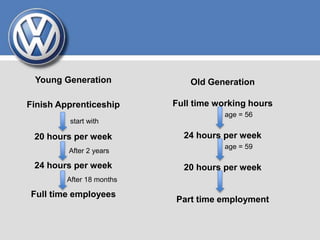

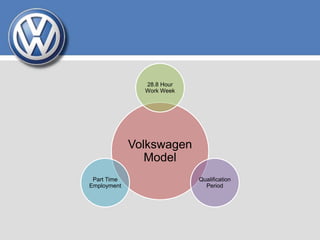

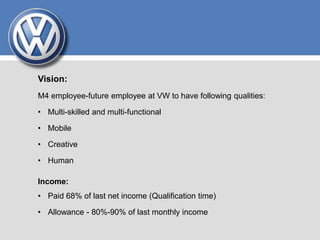

- Volkswagen introduced an unconventional model that included a 28.8 hour work week distributed over 4 days, qualification periods for employees, and part-time employment for older workers.

- This model resulted in a 10% wage reduction but a 13% decrease in costs, showing it was a more effective solution than traditional mass dismissal approaches.