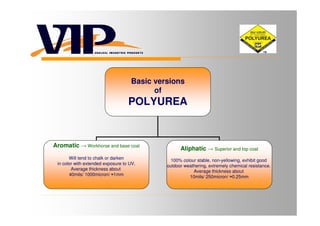

This document summarizes polyurea, a high-performance polymer coating. [1] It provides rapid cure times, is flexible, waterproof, and has outstanding physical properties. [2] It can be applied through low or high-pressure spray methods. [3] Different formulations include aromatic, aliphatic, and hybrid types suited for various applications like infrastructure, transportation, flooring, and more.