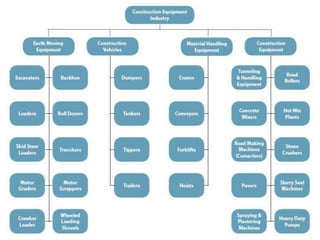

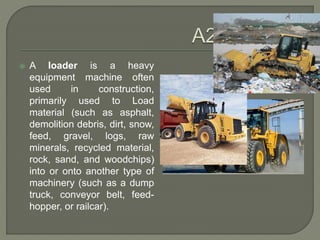

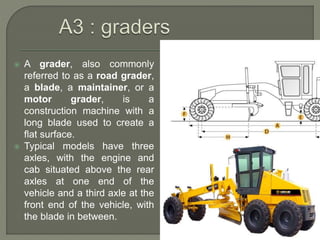

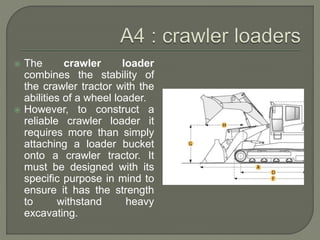

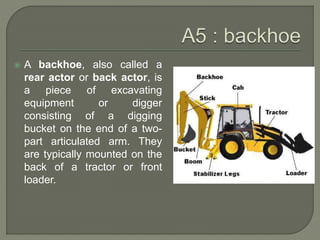

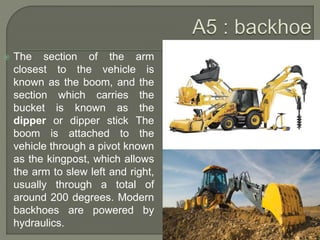

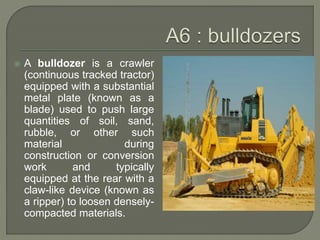

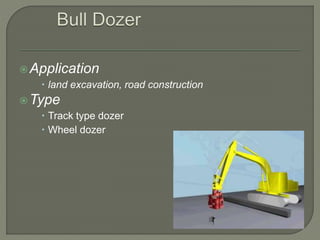

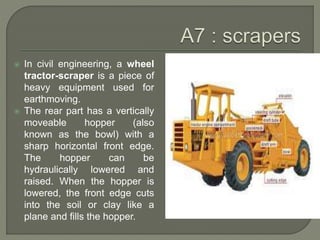

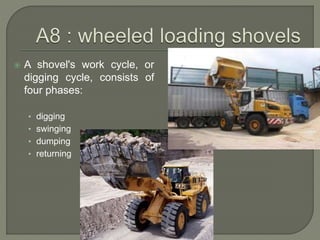

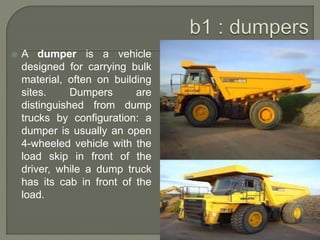

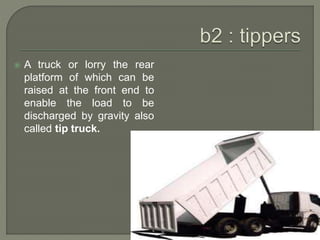

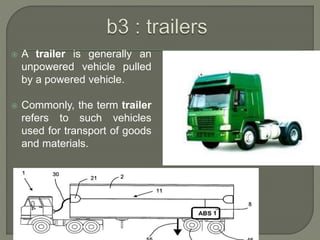

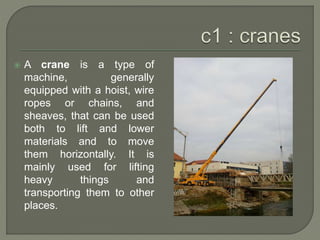

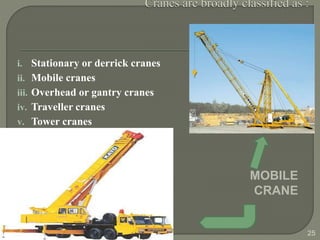

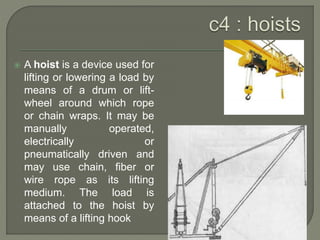

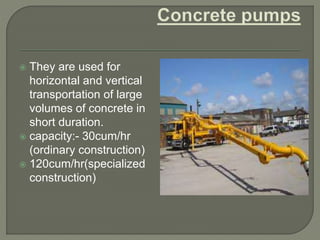

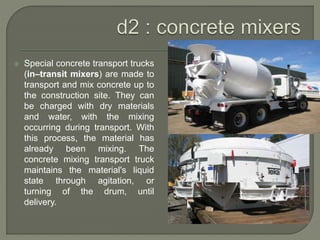

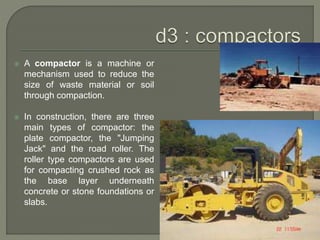

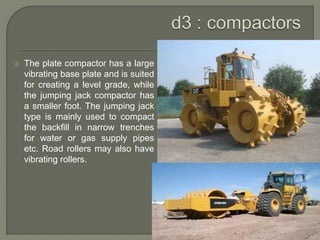

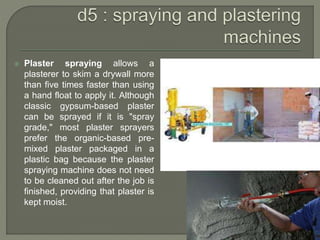

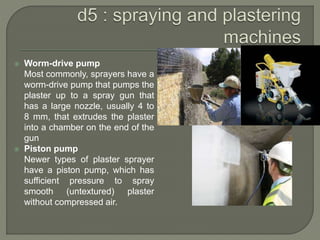

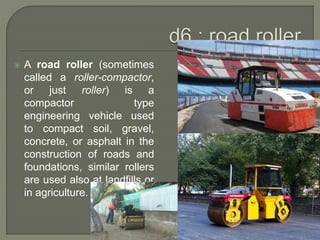

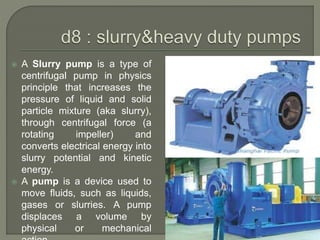

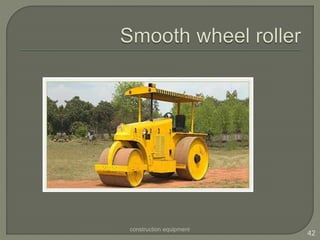

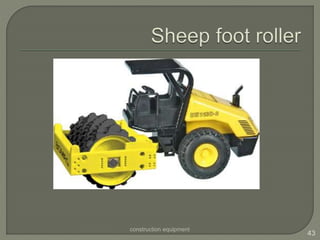

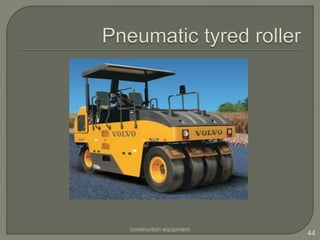

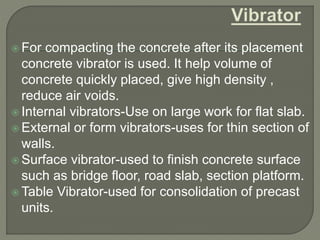

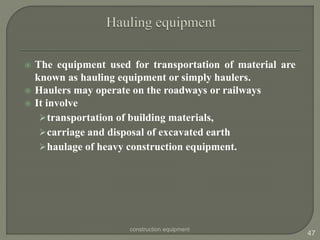

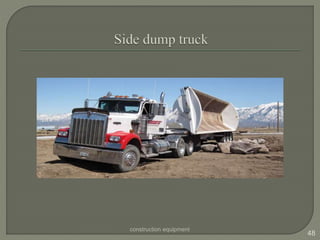

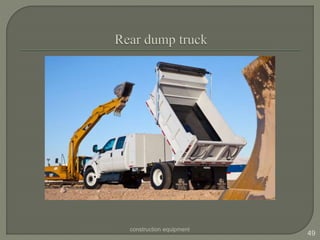

The document discusses various types of construction equipment used in earthmoving and building activities. It describes excavators, loaders, graders, bulldozers, backhoes, dump trucks, tipper trucks, trailers, cranes, conveyor systems, forklifts, hoists, concrete mixers, compactors, plaster sprayers, road rollers, slurry pumps, vibrators, and haulers. The equipment is used for tasks like digging, loading, hauling, lifting, mixing, compacting, spraying, transporting materials, and consolidating concrete.