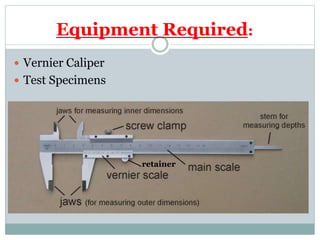

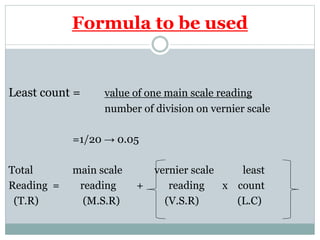

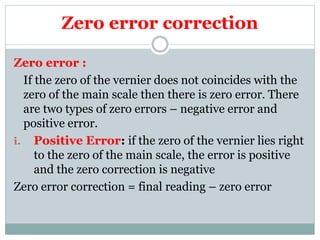

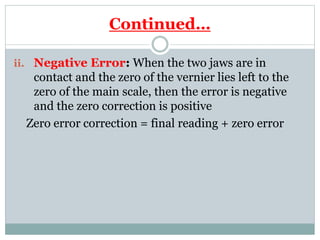

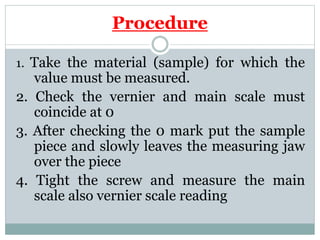

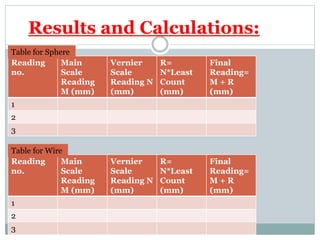

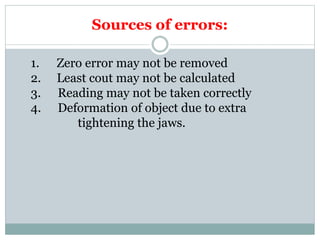

A Vernier caliper is a tool used to take precise linear measurements. It has a main scale and sliding Vernier scale that allows measurements within 0.05 mm. The document describes the parts of a Vernier caliper including the jaws, probe, scales, and screw clamp. It provides the formula to calculate measurements from the main and Vernier scale readings taking into account the least count of 0.05 mm. The procedure for using a Vernier caliper to measure specimens is outlined, including checking for zero error, taking readings from the scales, and calculating the final measurement. Sources of error in using the Vernier caliper are also discussed.