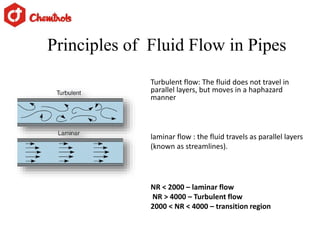

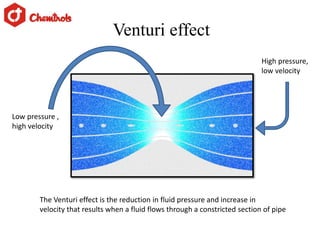

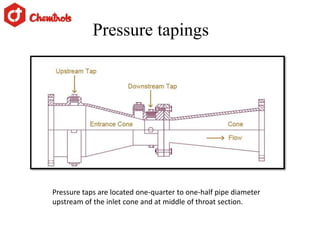

The document summarizes the principles and operation of a Venturi tube flow meter. It works by measuring the pressure difference between the upstream inlet and throat of a constricted venturi section. Fluid flowing through the converging cone experiences a drop in pressure and increase in velocity at the throat. Factors like pipe diameter, materials, pressure ratings, and installation styles are considered in the design. Advantages include handling large flows with low pressure drops, while limitations include bulkiness and high installation/usage costs. The document provides details on standards, sizes, materials, and mounting options that Chemtrols Industries offers for venturi tube flow meters and their targeted industrial clients.