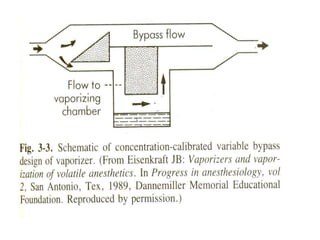

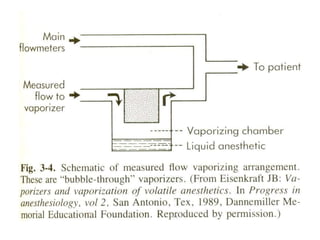

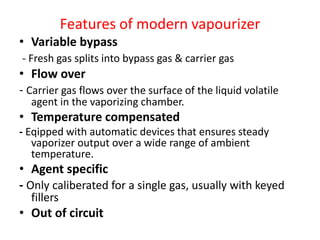

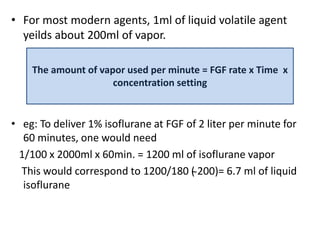

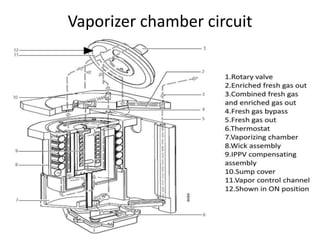

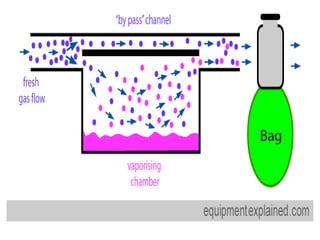

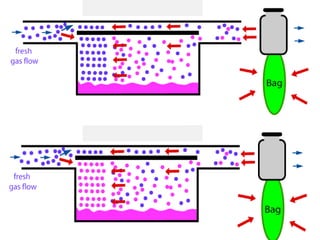

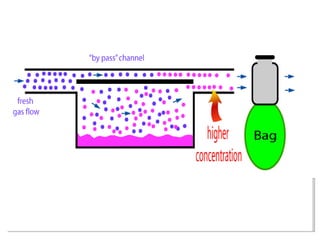

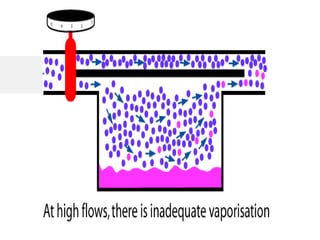

1. Vaporizers are devices that change liquid anesthetic agents into vapor for delivery to patients. They work by allowing gas to flow over or bubble through the liquid agent in a vaporizing chamber.

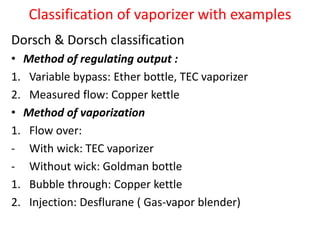

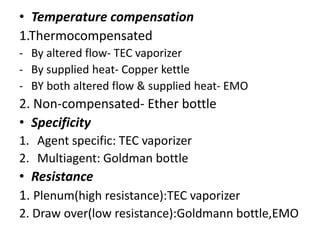

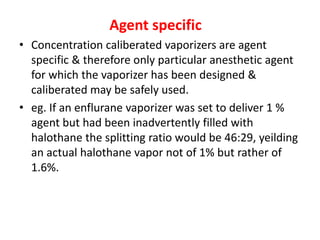

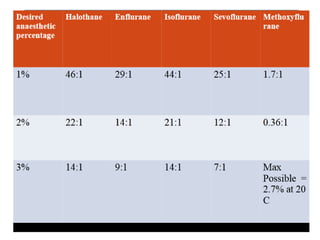

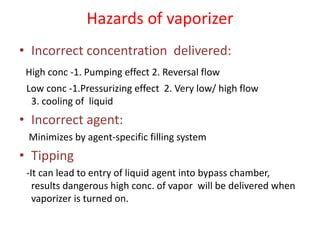

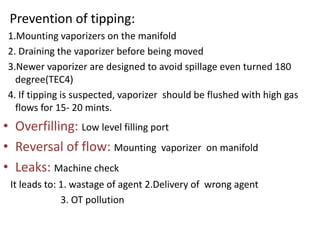

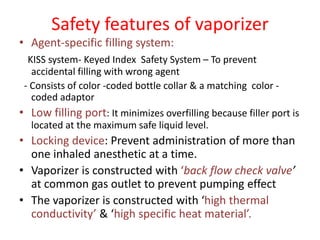

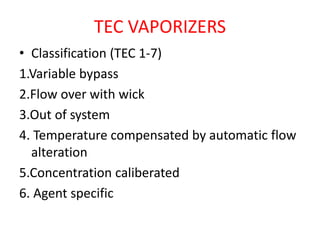

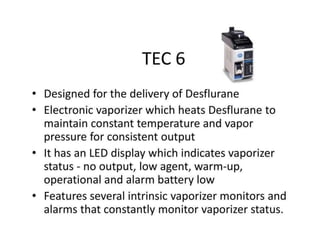

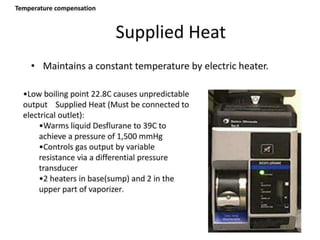

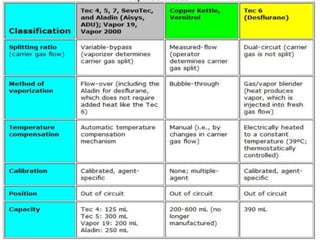

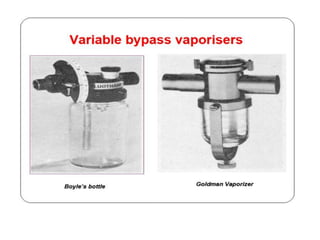

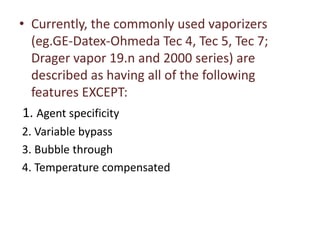

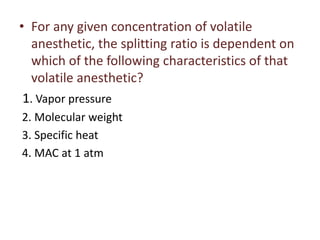

2. Modern vaporizers are specifically designed for individual agents, have temperature compensation, and feature variable bypass mechanisms to regulate vapor concentration.

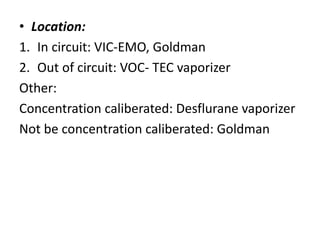

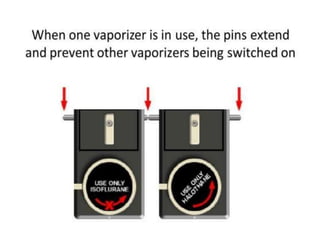

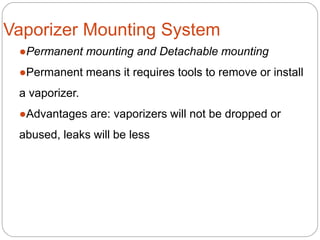

3. Placement of vaporizers between the common gas outlet and breathing system on the anesthesia machine is an acceptable location.