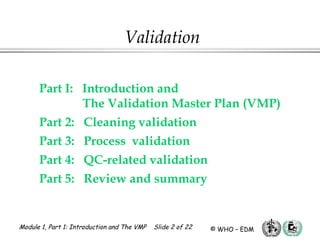

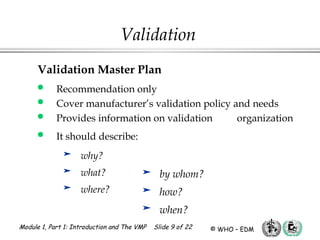

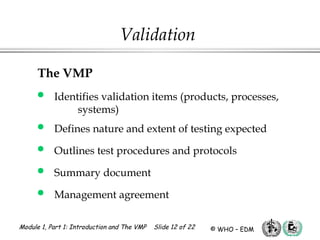

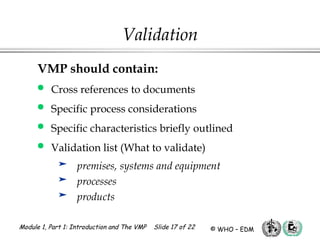

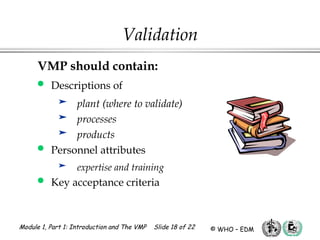

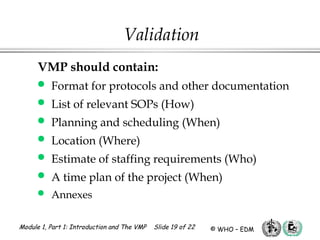

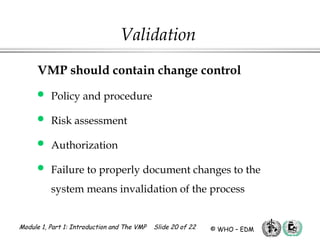

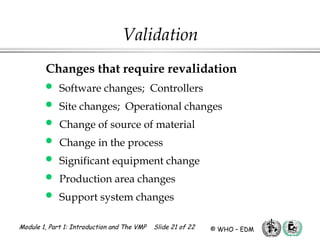

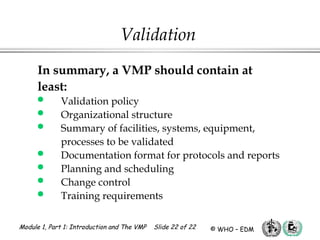

The document provides an overview of the Validation Master Plan (VMP) as part of good manufacturing practices (GMP) training. It outlines the definition of validation, its principles, objectives, and key components required in a VMP, including responsibilities, planning, scheduling, and change control. The VMP serves as a comprehensive guide for managing validation projects, ensuring quality assurance in processes and systems.