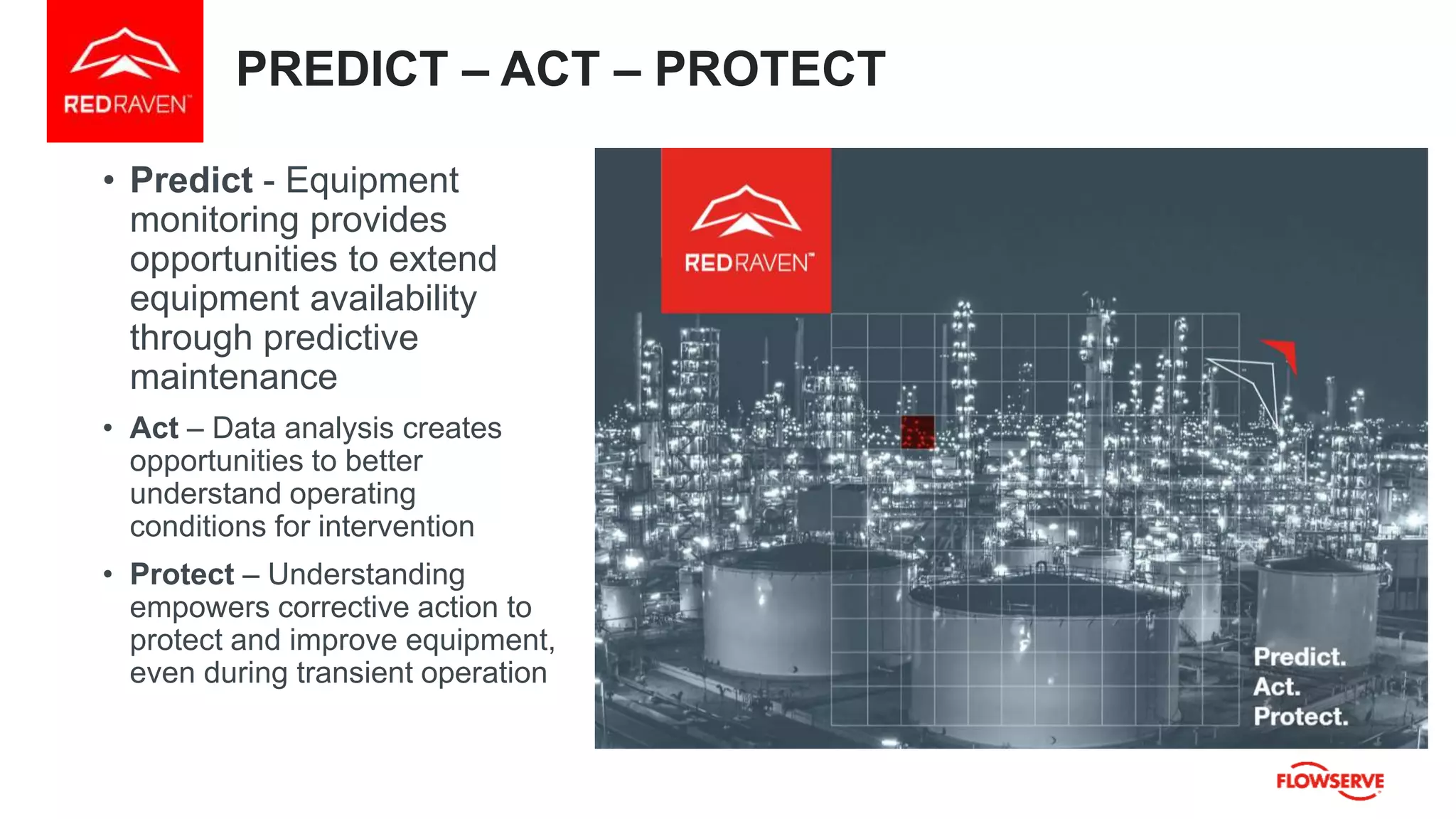

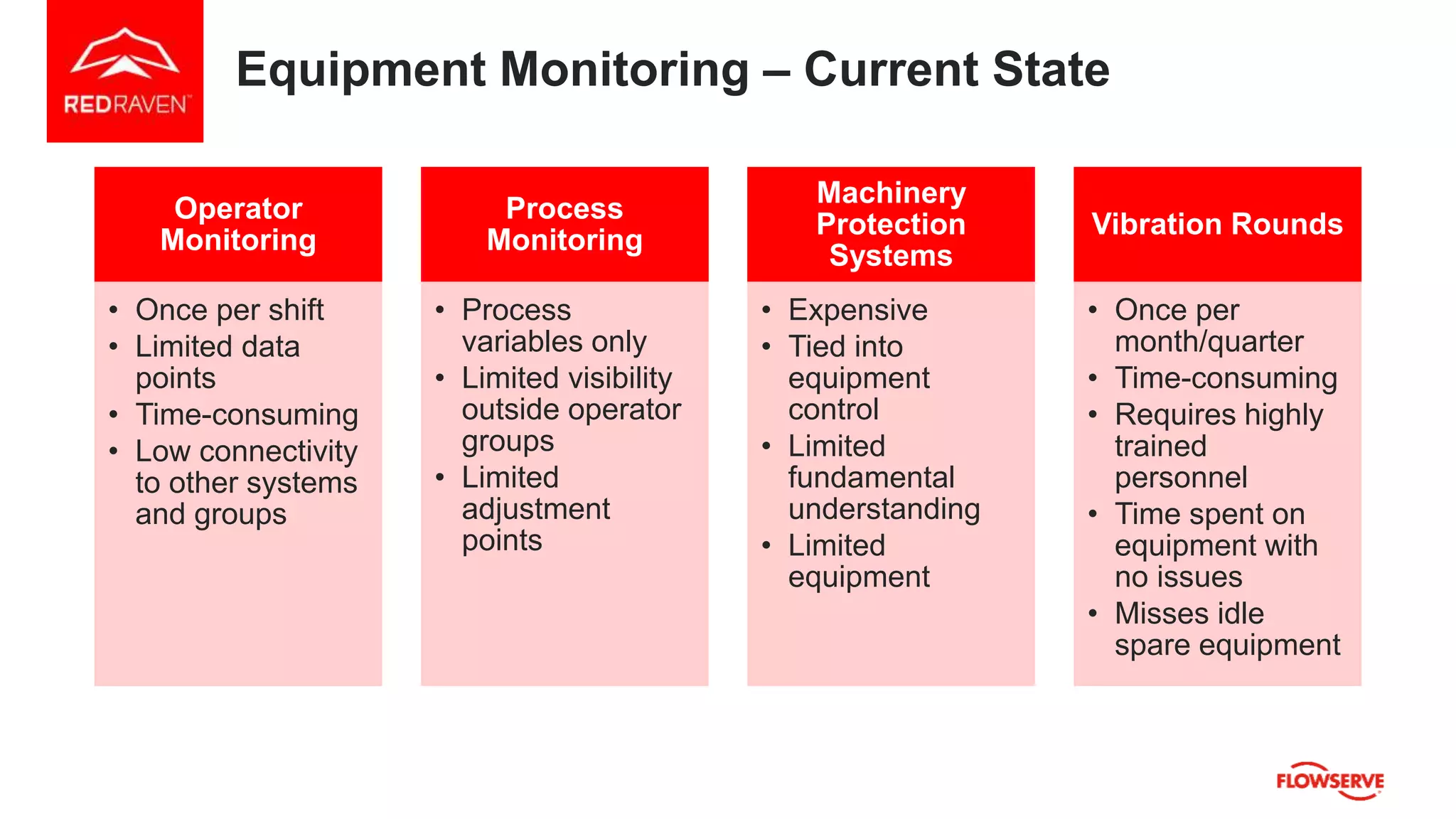

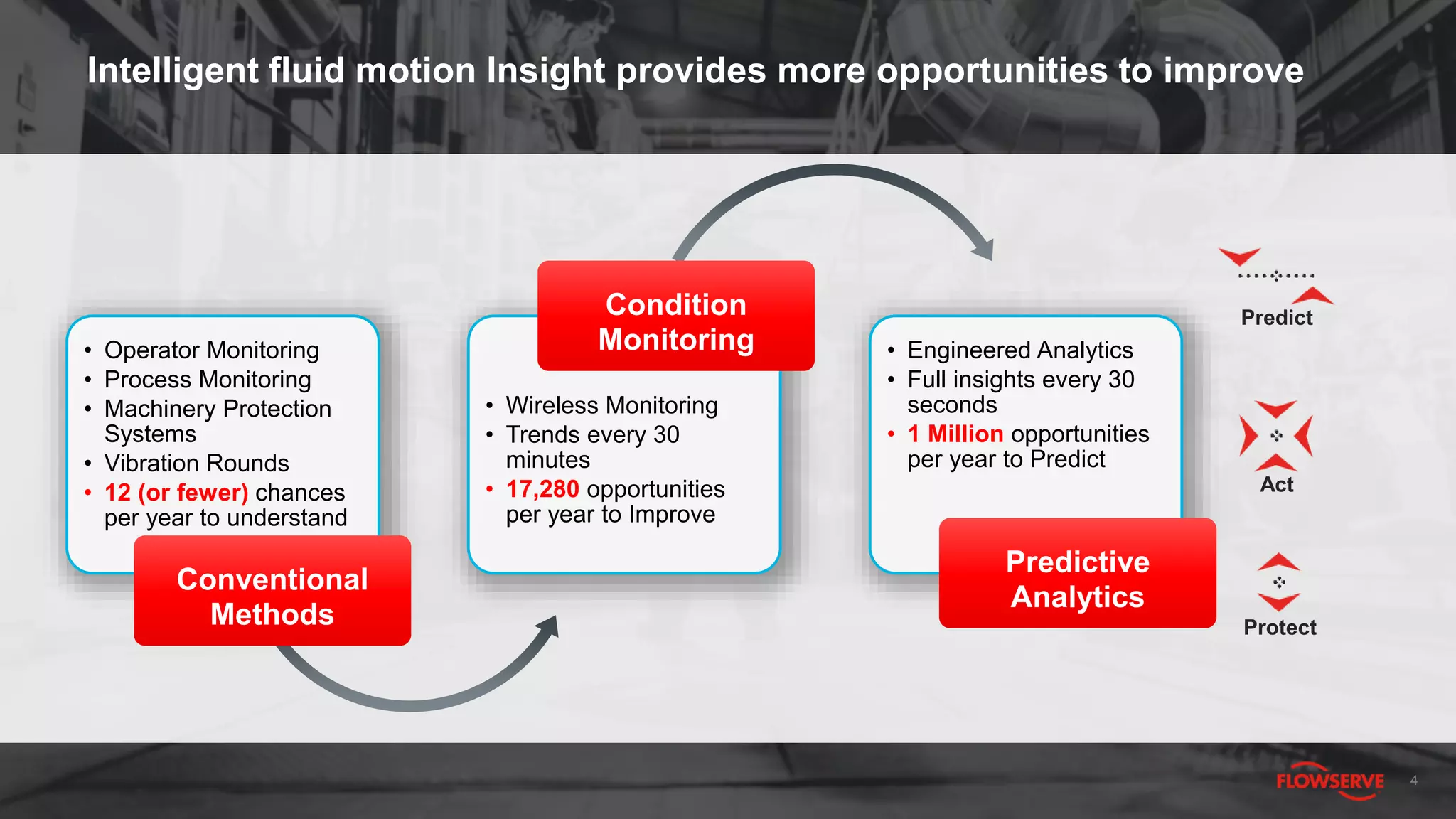

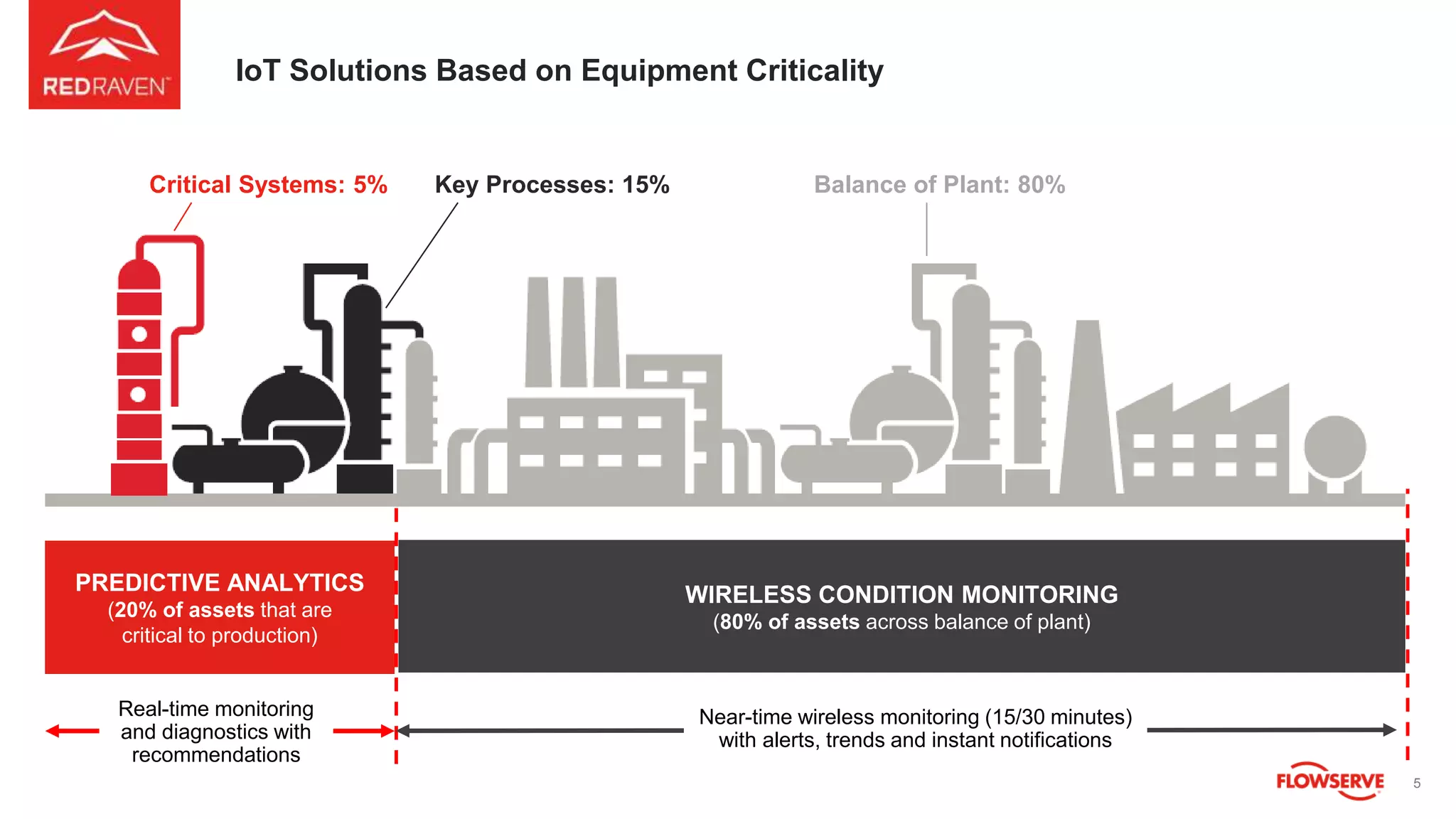

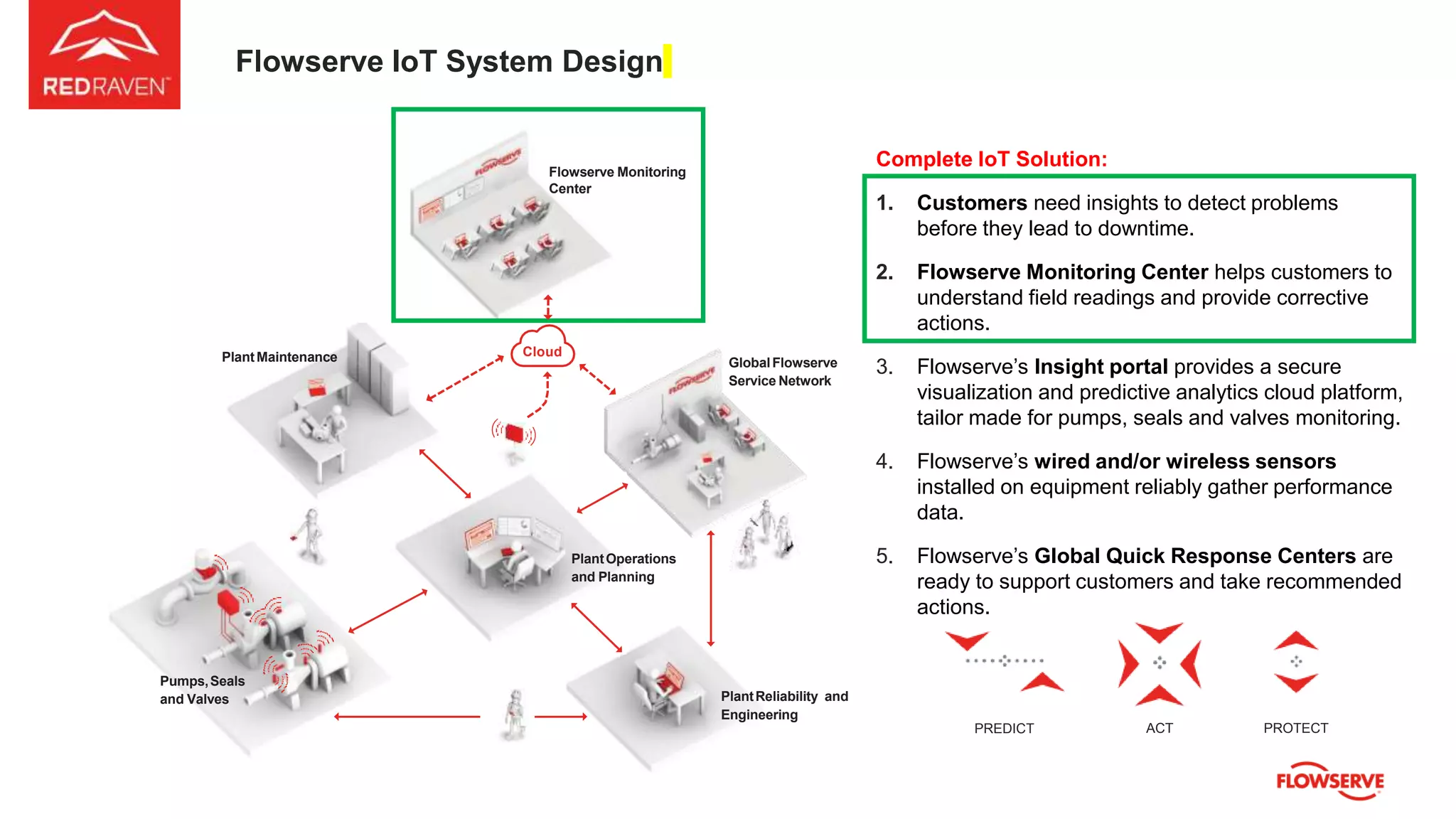

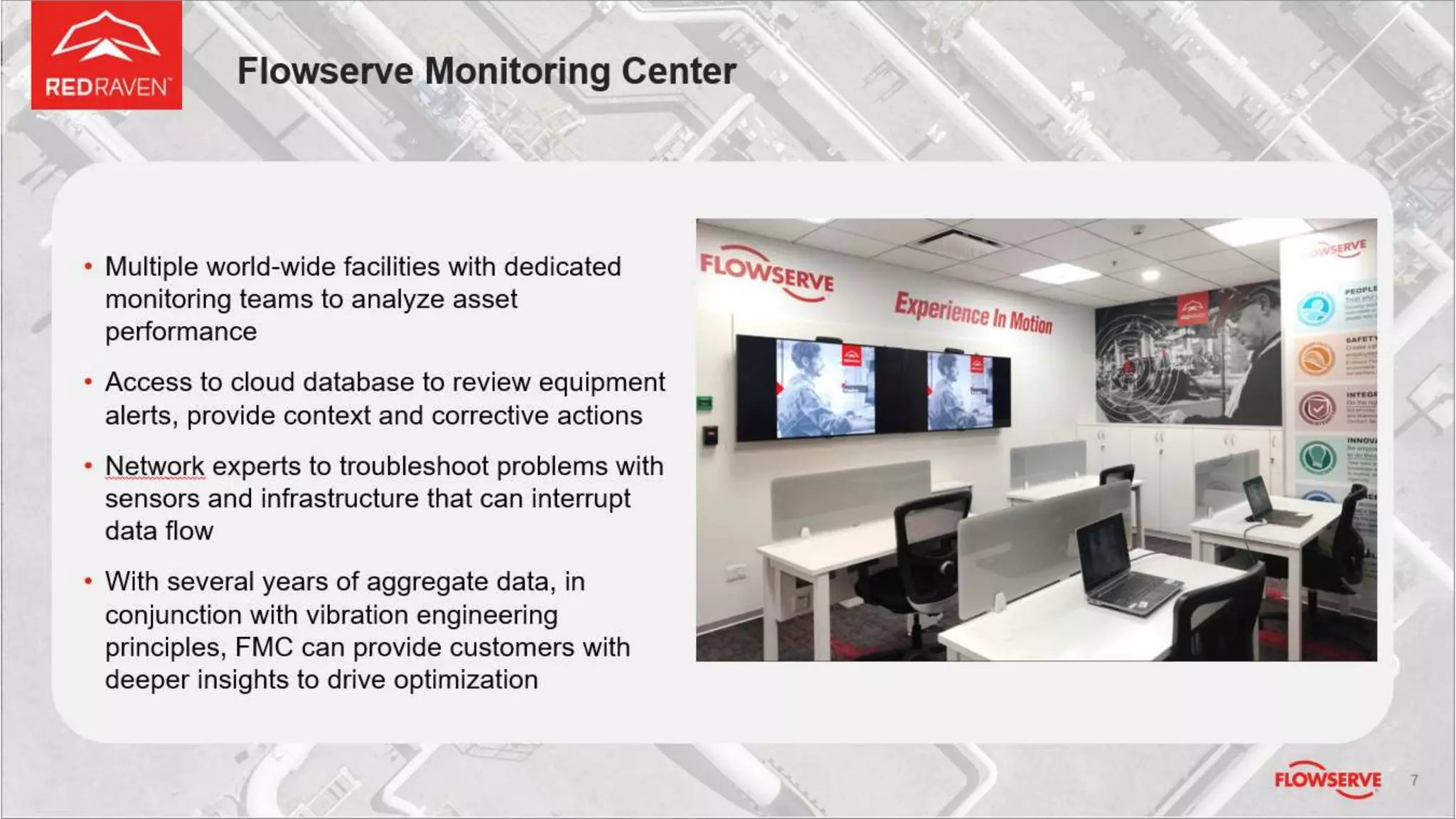

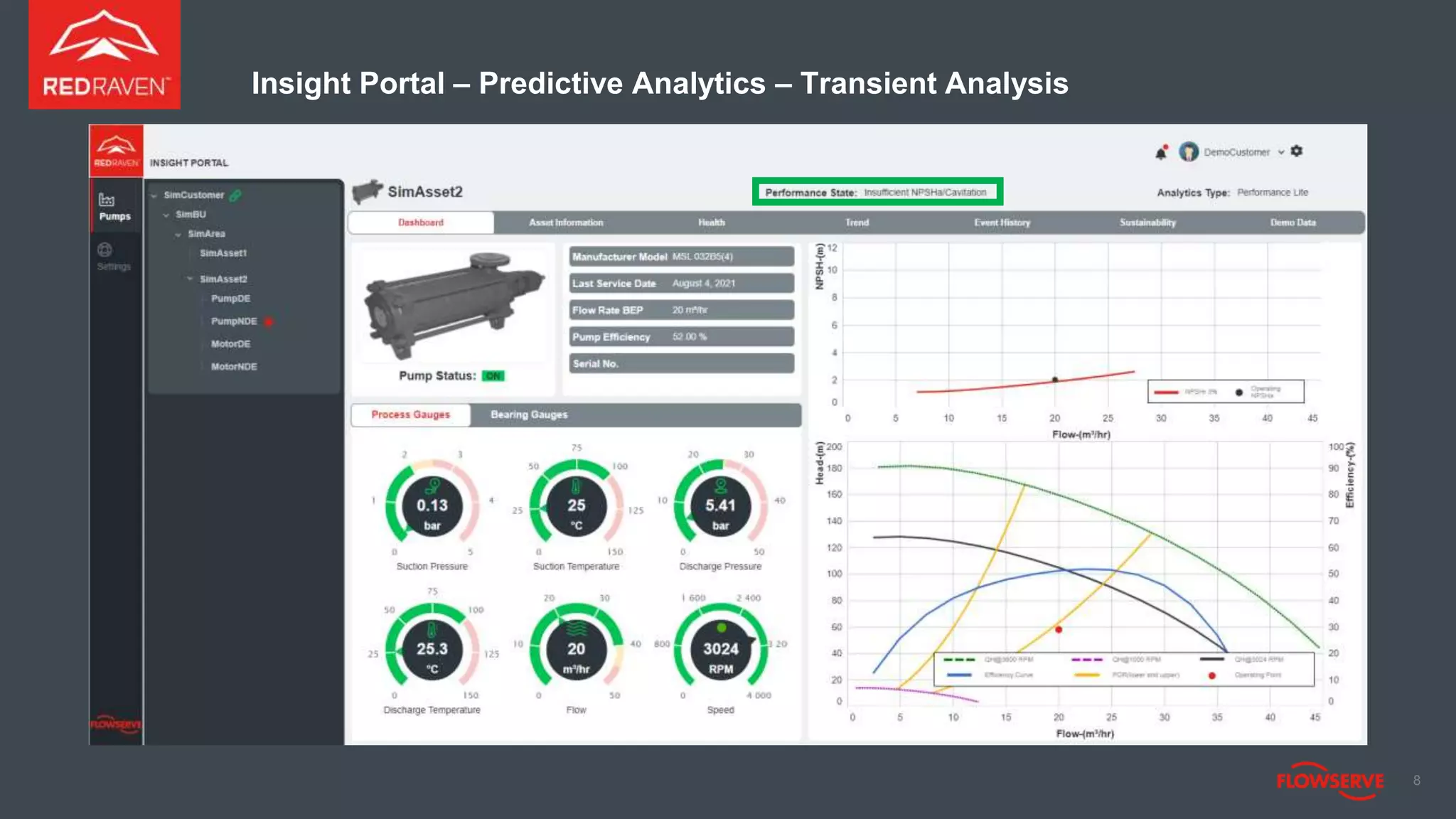

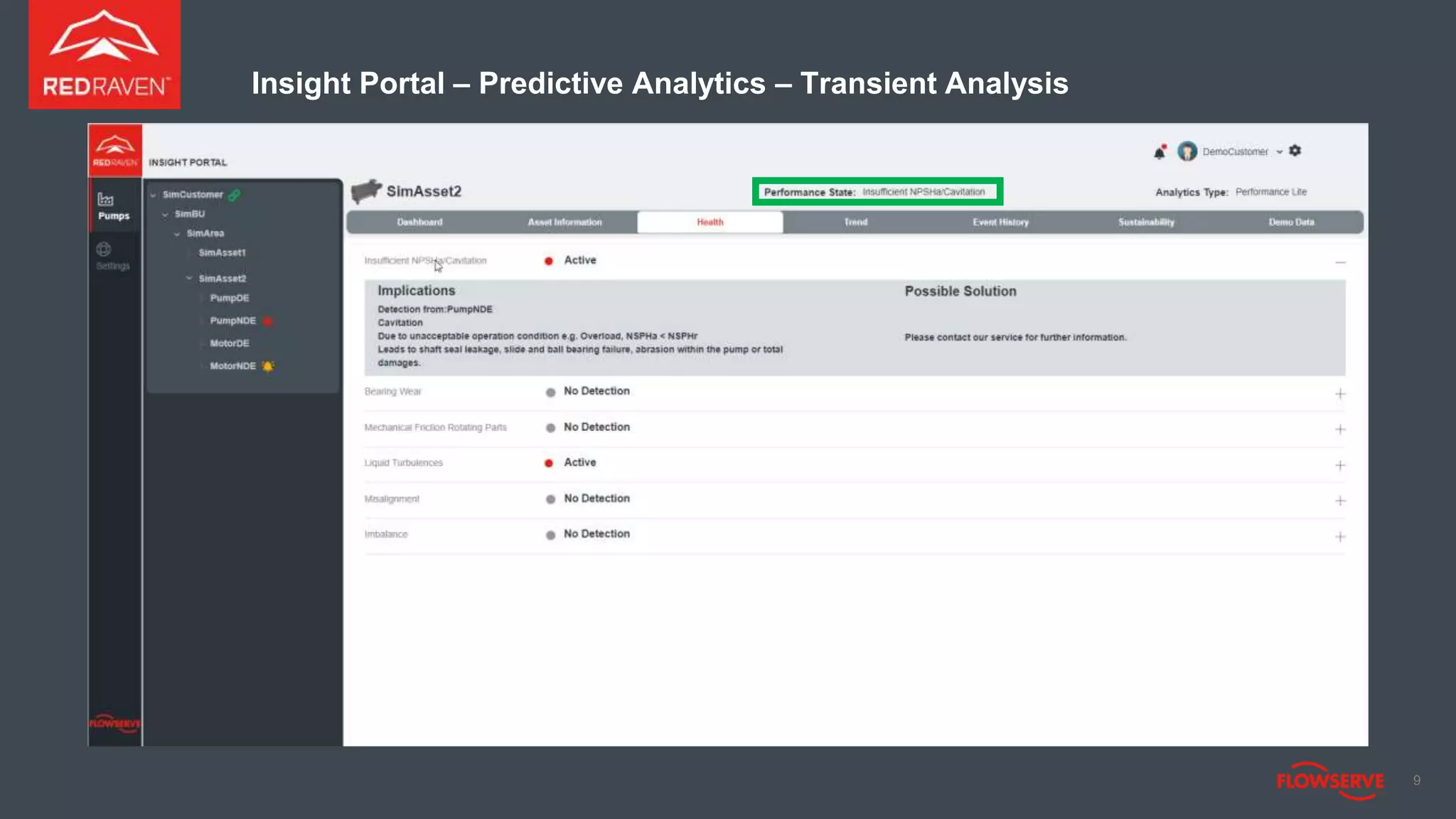

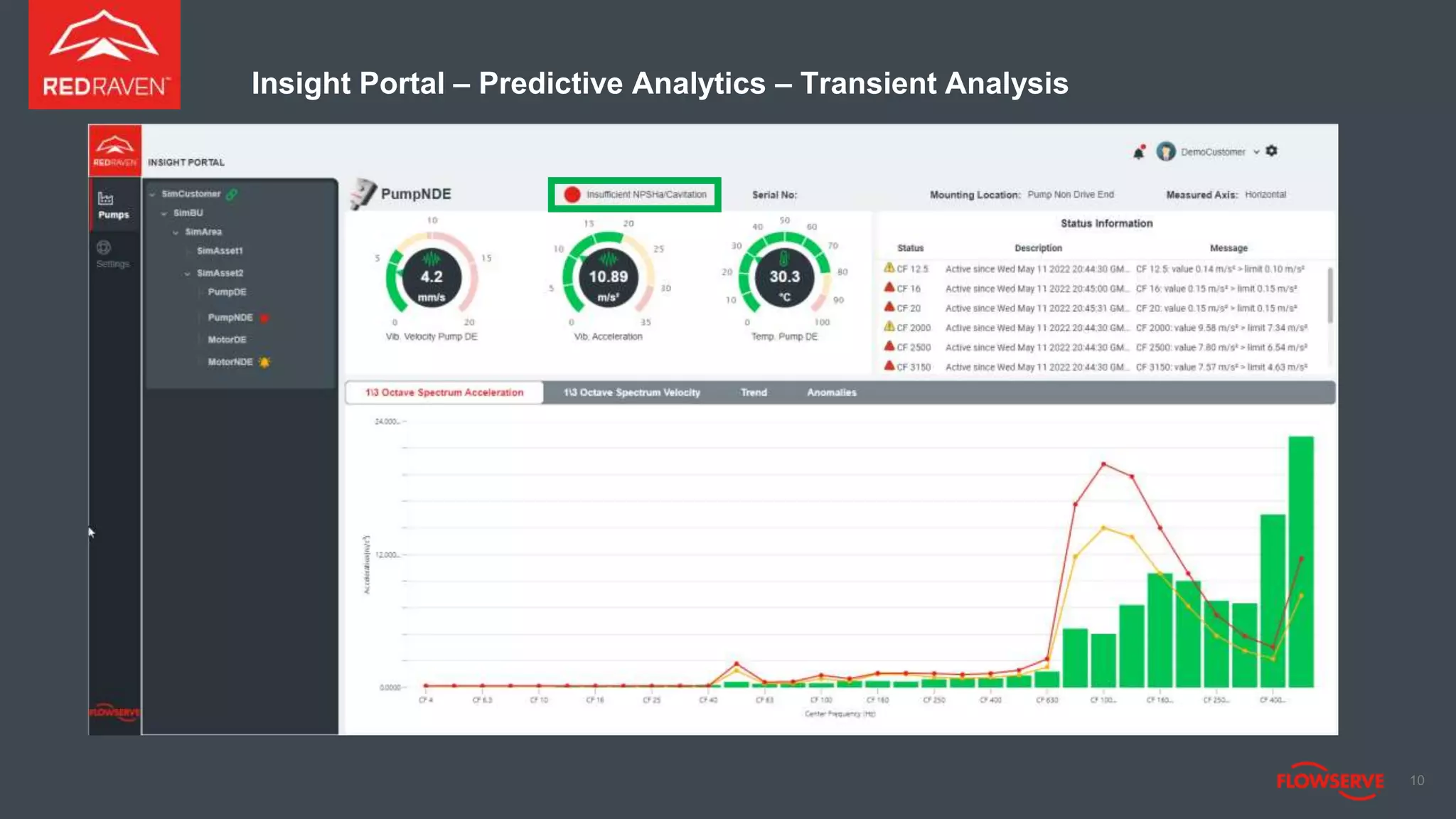

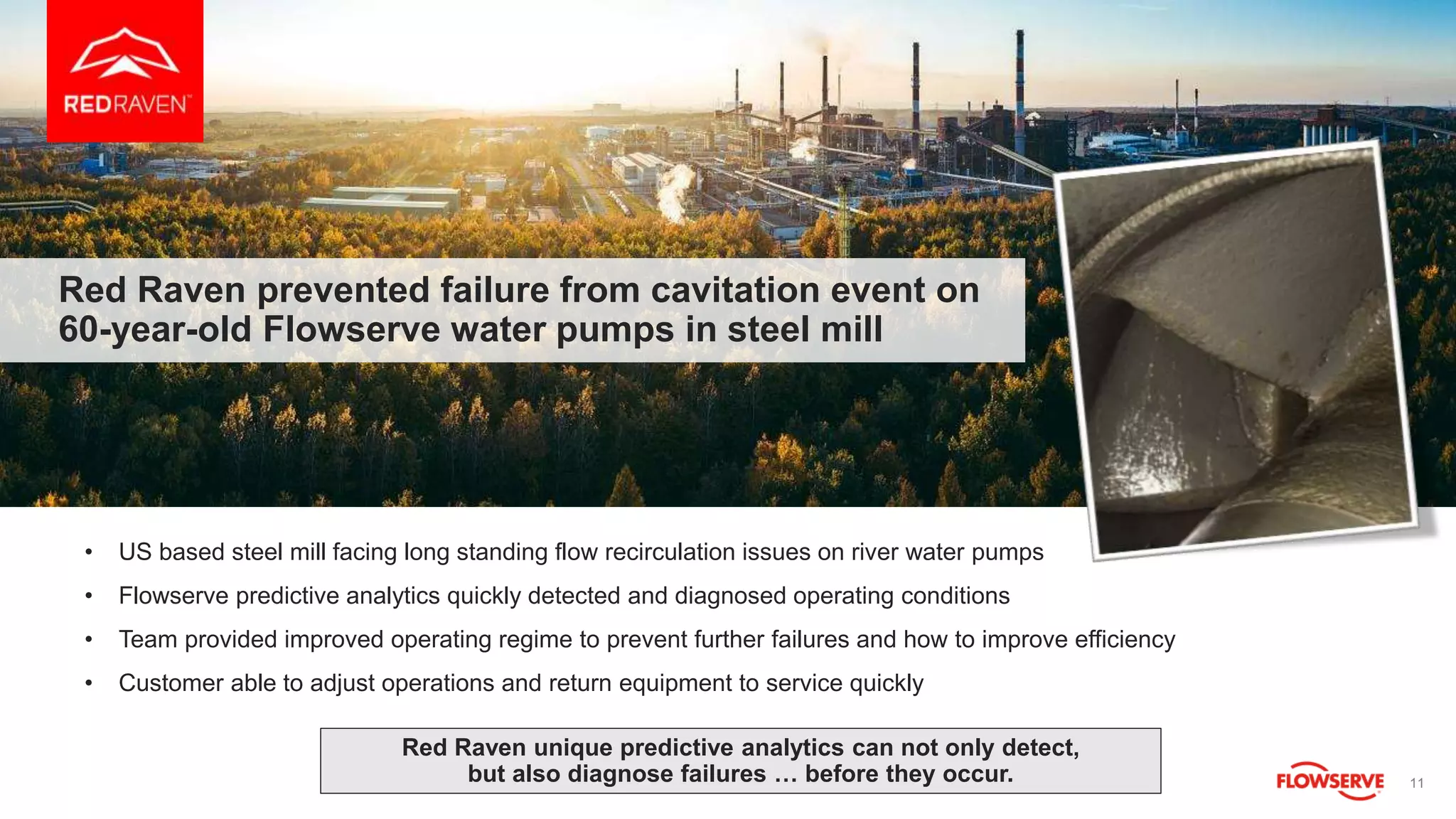

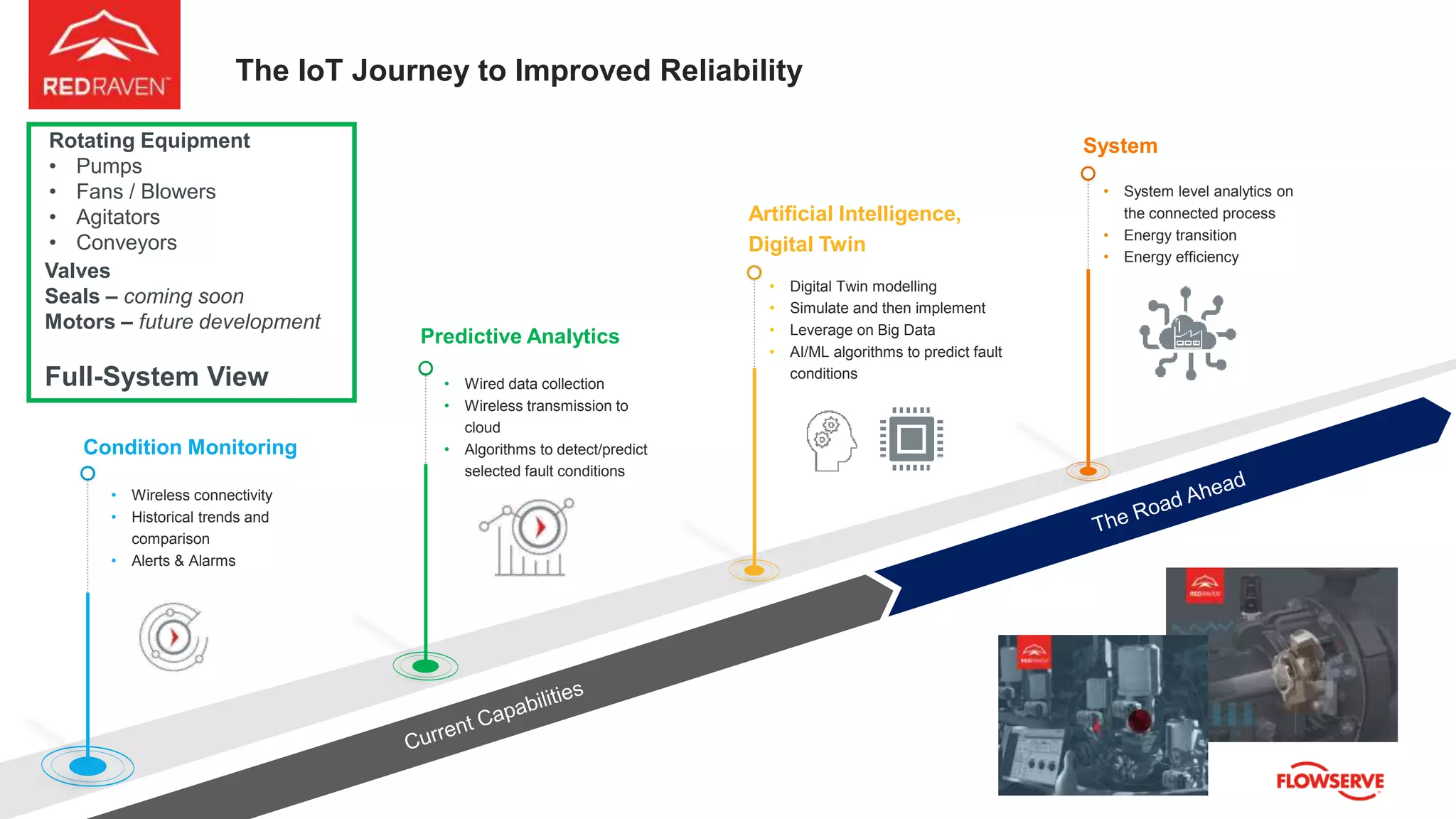

The document discusses using condition monitoring and predictive analytics to improve equipment reliability. It describes current monitoring methods that only check equipment periodically and miss issues. Intelligent monitoring collects frequent sensor data to detect problems through trends. This enables predictive maintenance by understanding operating conditions. Analytics can then recommend actions to protect equipment and improve performance. The system uses wireless monitoring on most assets and real-time monitoring on critical equipment. The monitoring center helps customers understand data and take corrective actions. The goal is connecting customers, equipment, and experts to predict and prevent failures. Examples show how the system has helped customers detect problems, avoid downtime, and prevent damage.