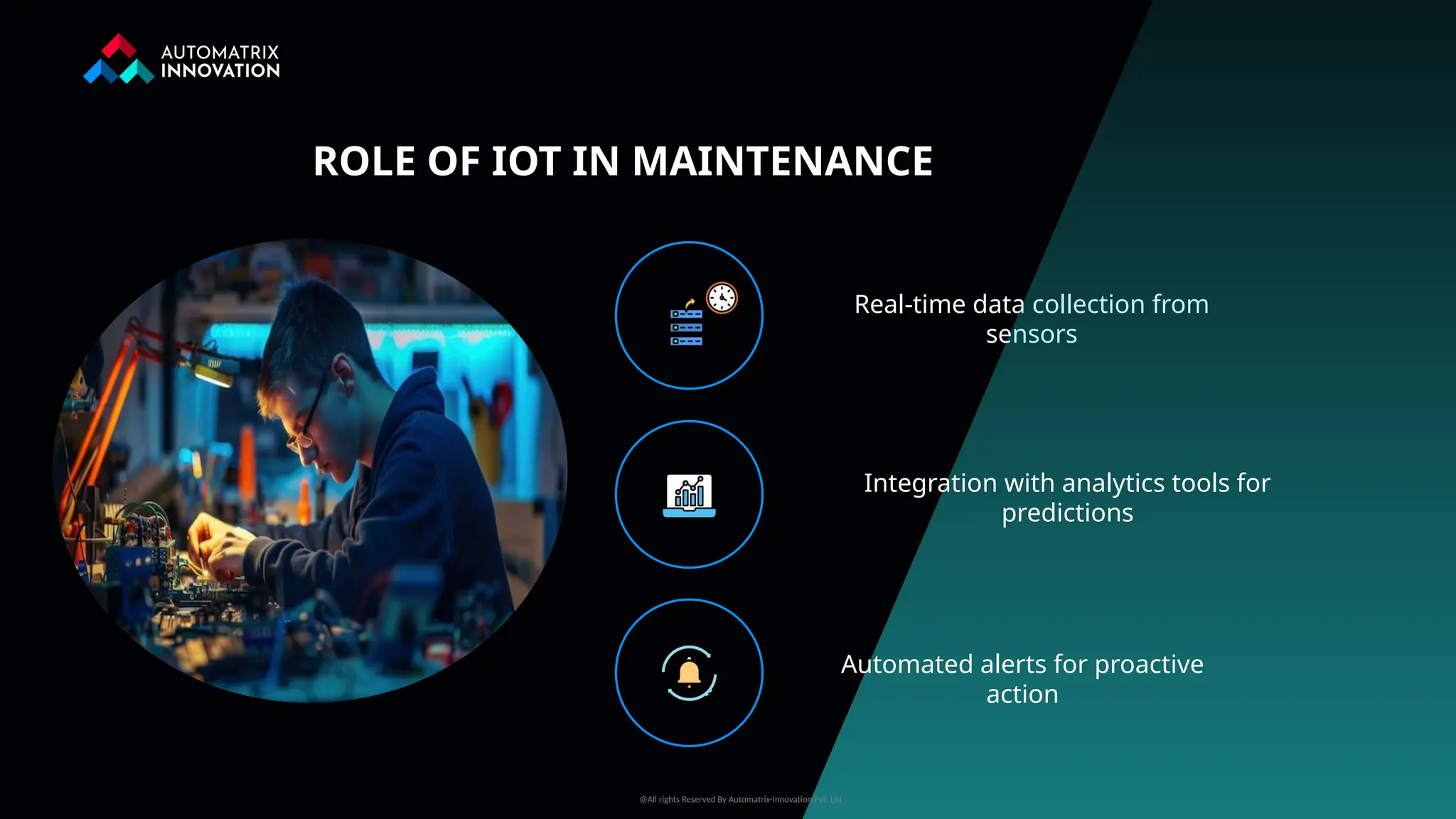

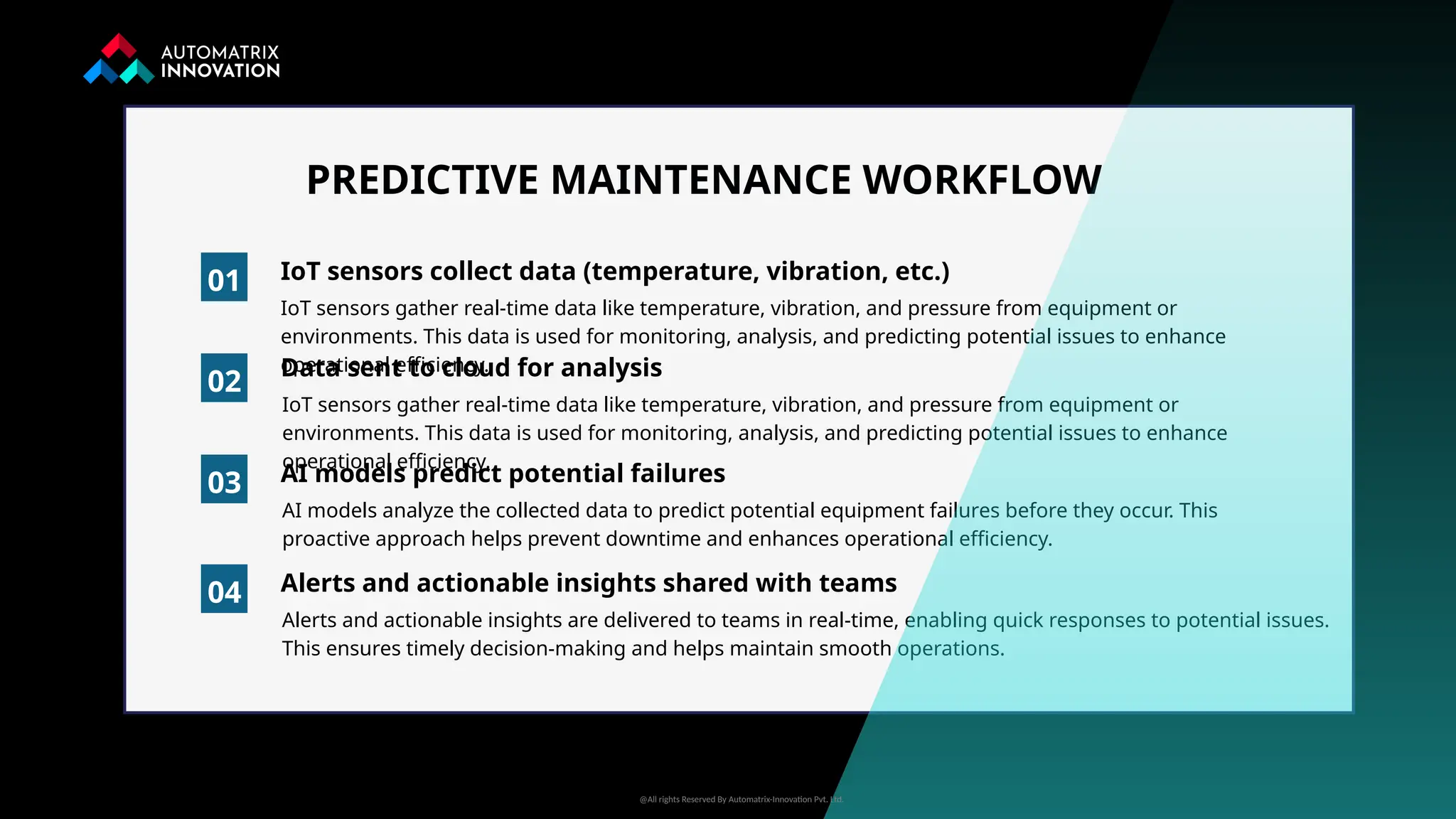

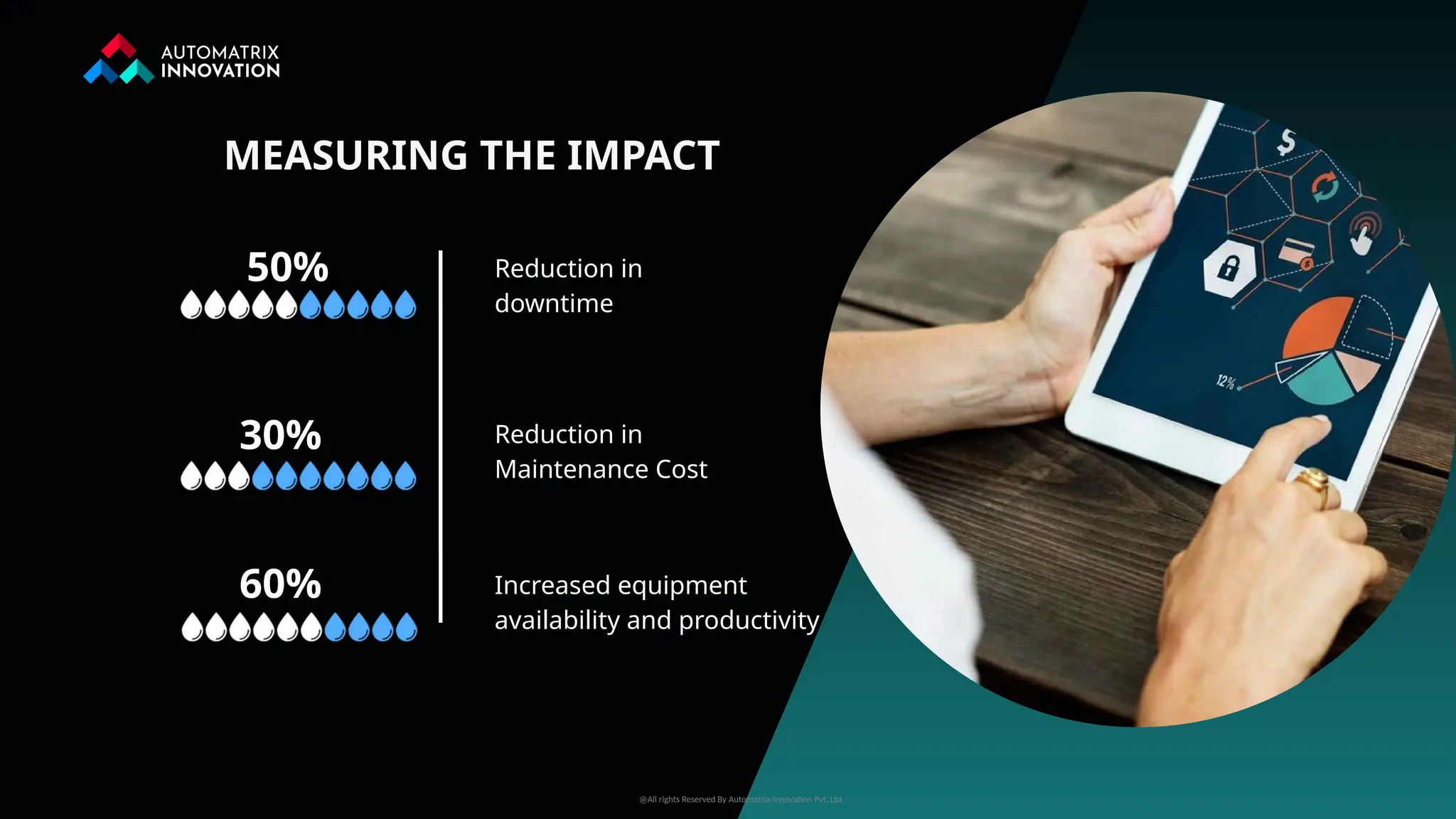

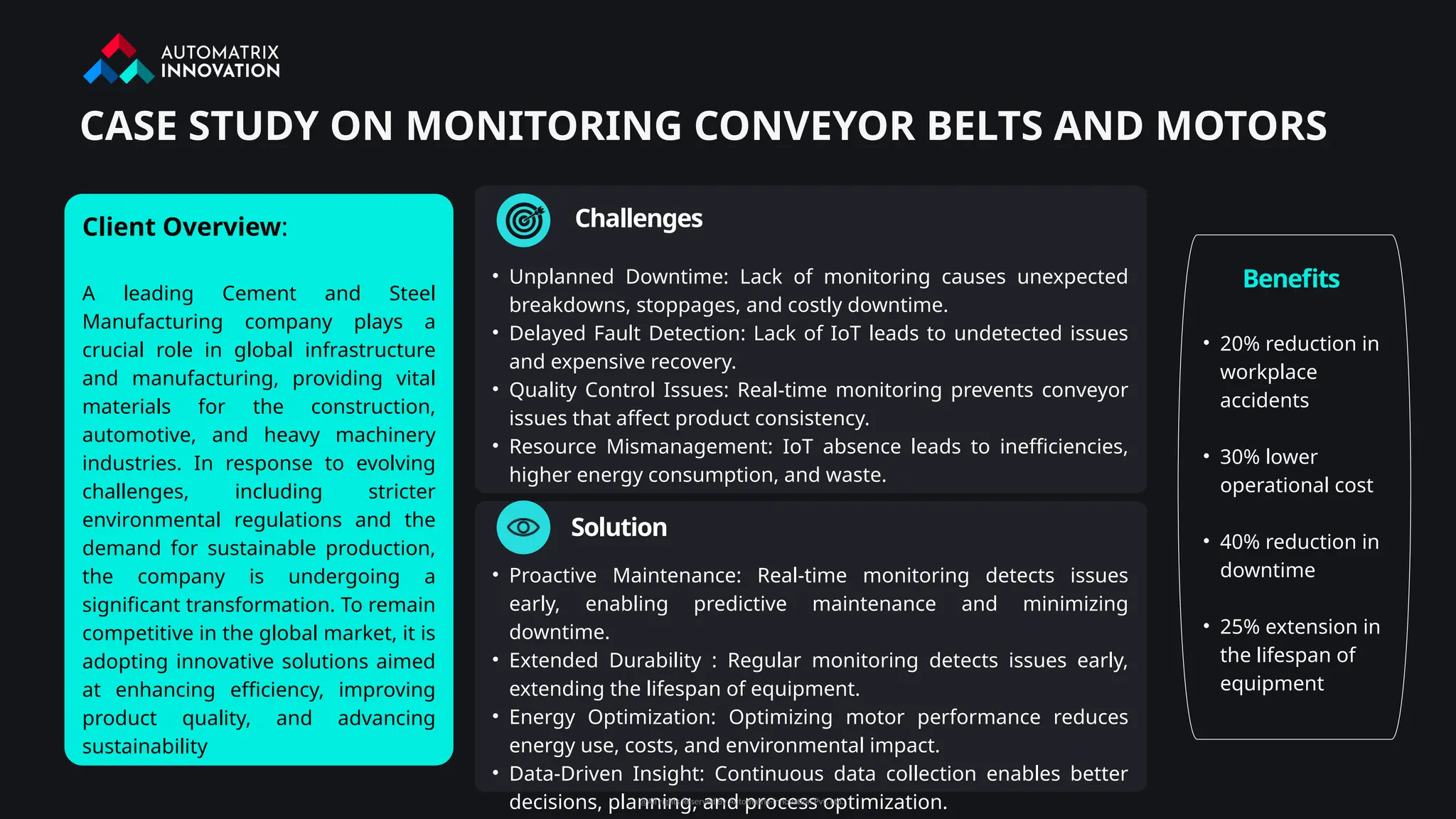

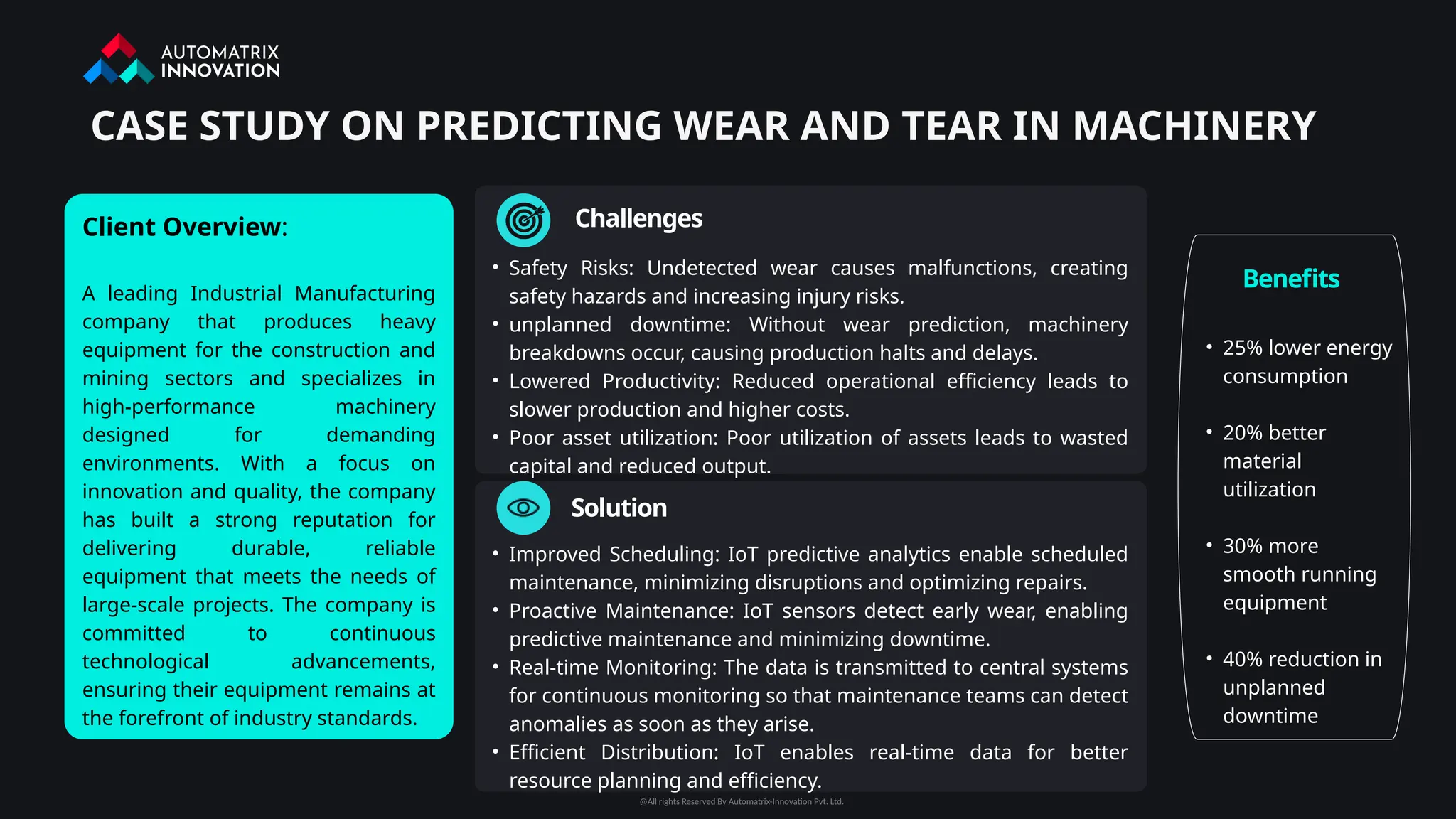

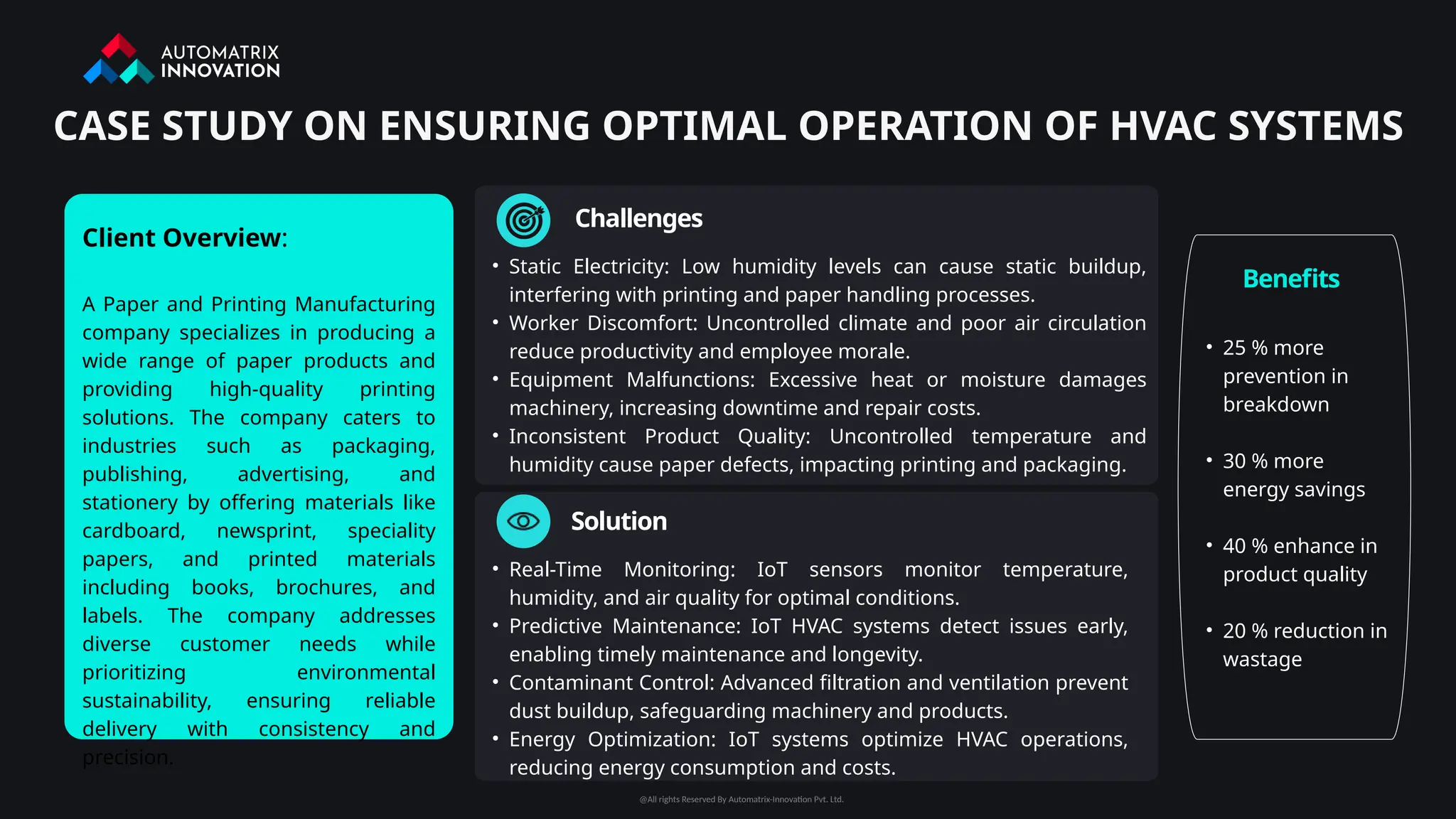

The document discusses the implementation of predictive maintenance in manufacturing using IoT technology, emphasizing the benefits like minimizing downtime, extending equipment lifespan, and reducing costs. It includes case studies from various industrial sectors showcasing the advantages of real-time data monitoring and analytics for proactive maintenance and operational efficiency. Key outcomes include significant reductions in maintenance costs, energy consumption, and operational downtime, alongside improved product quality and safety.