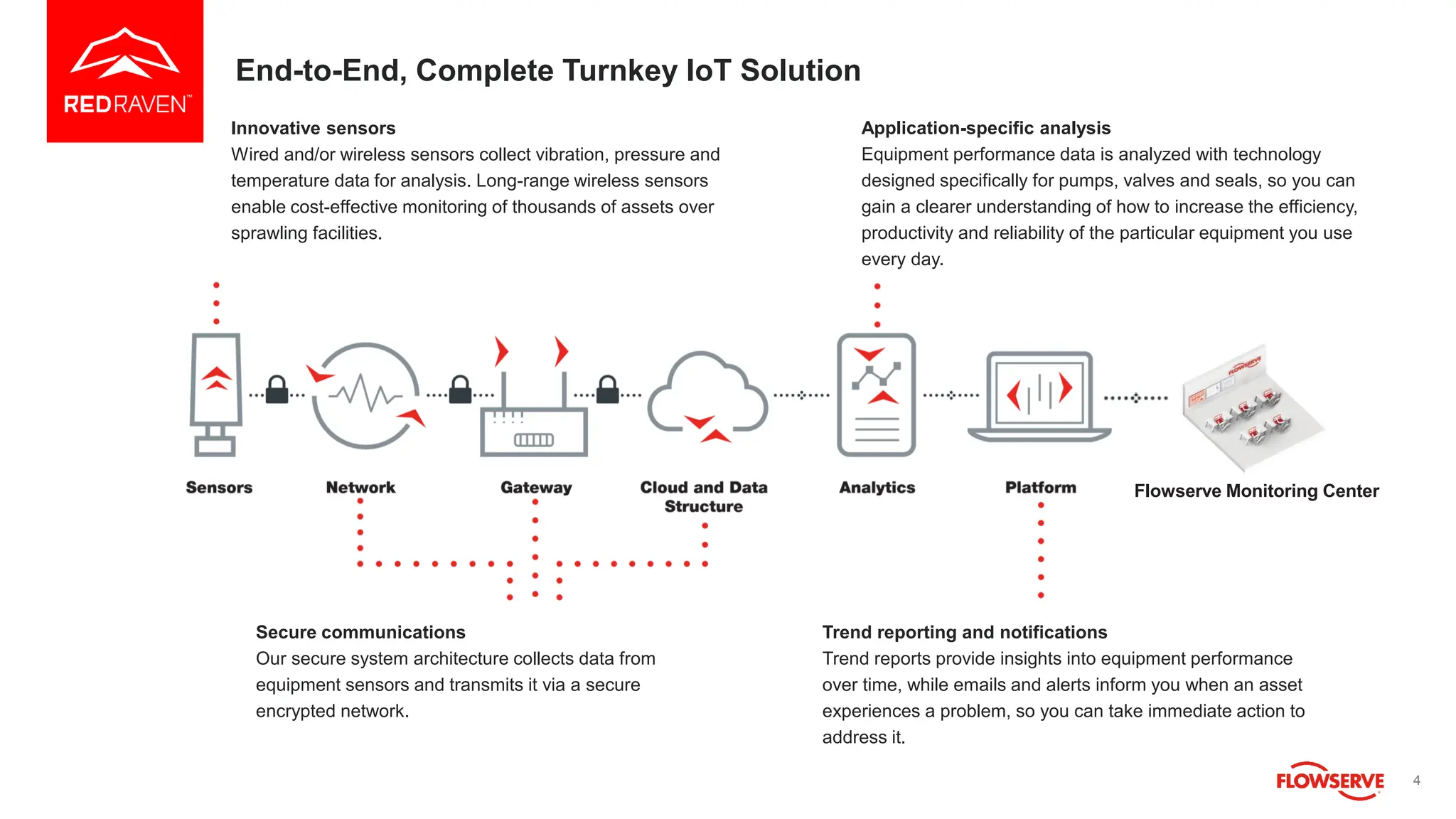

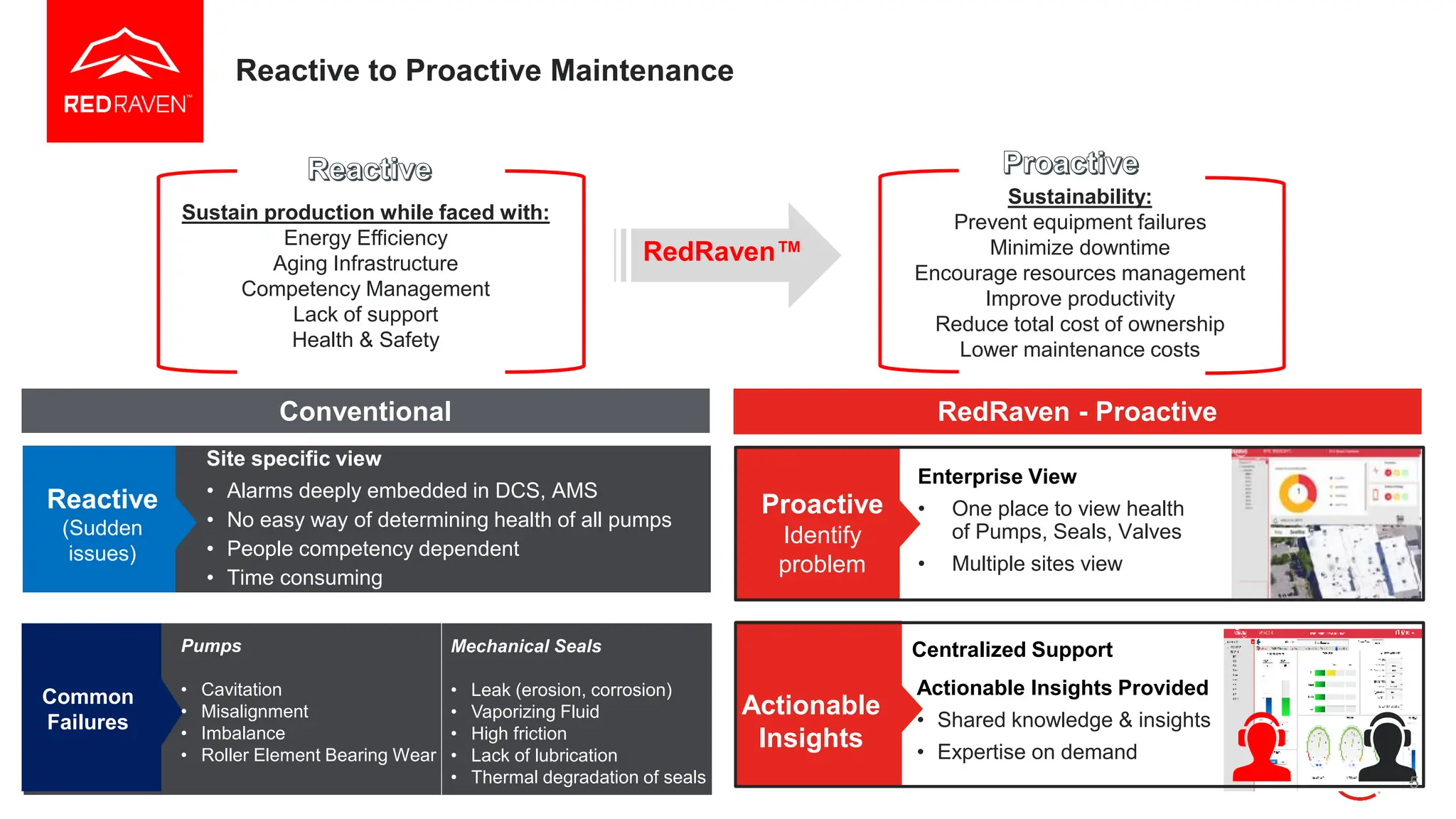

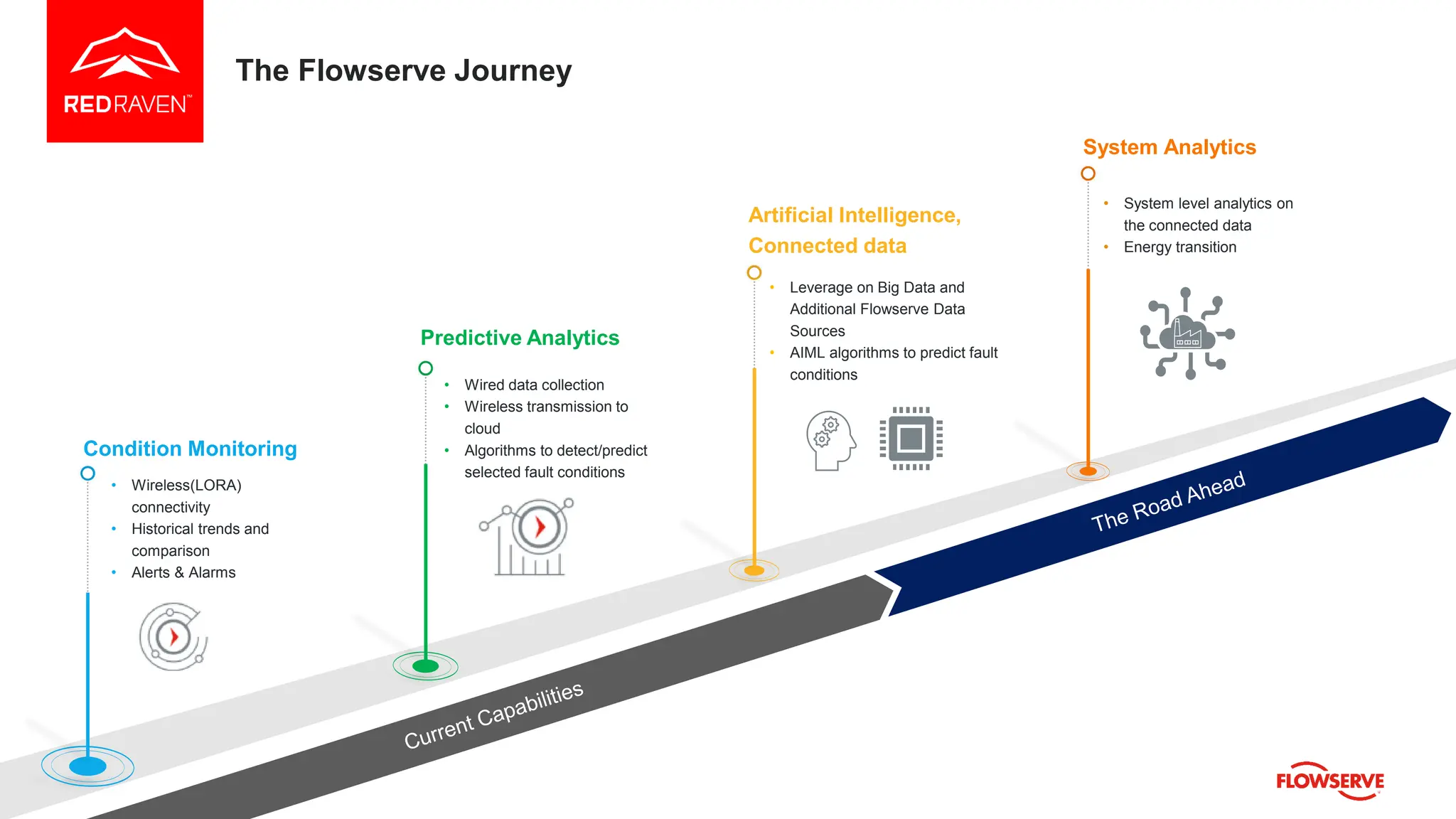

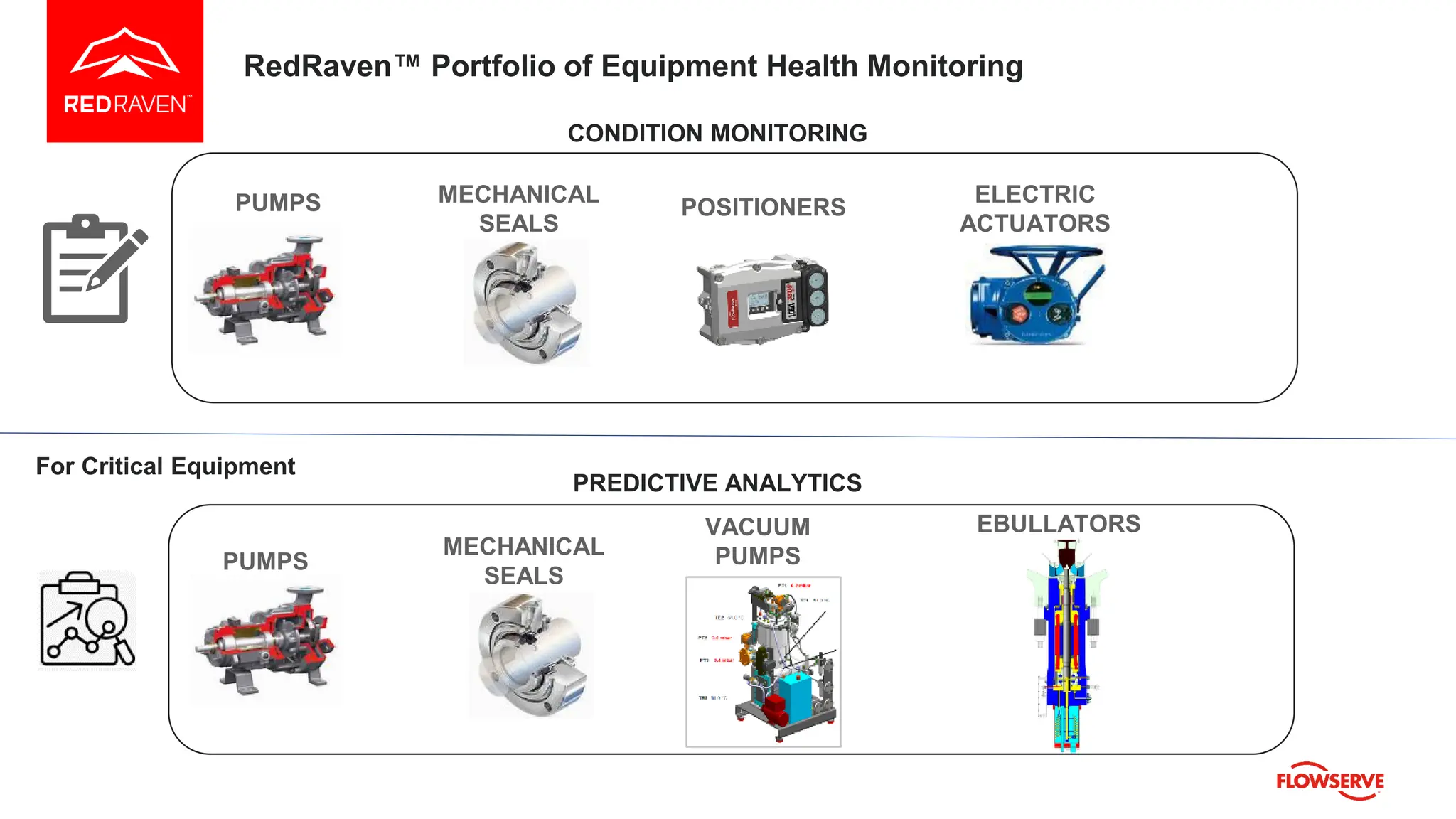

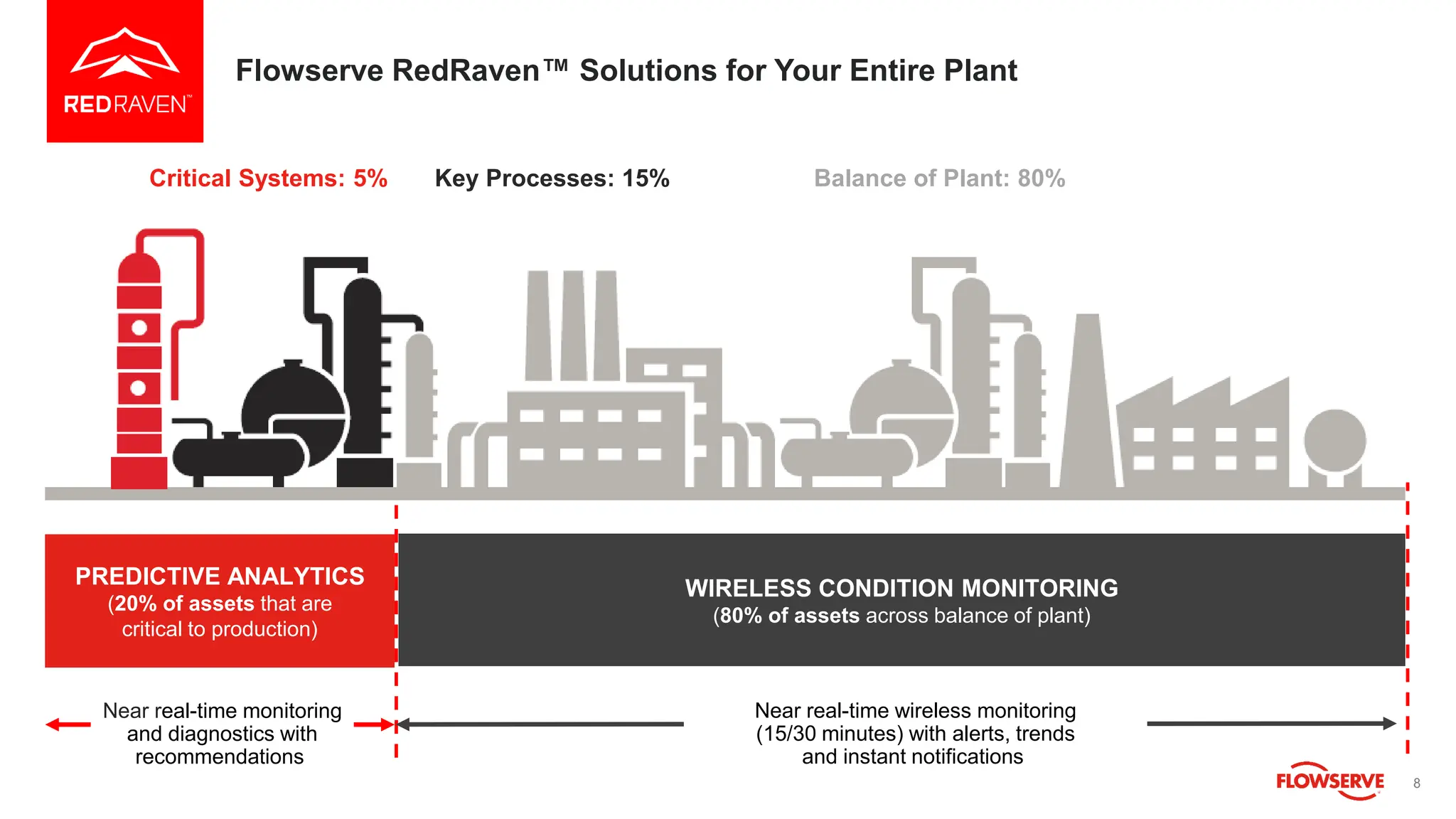

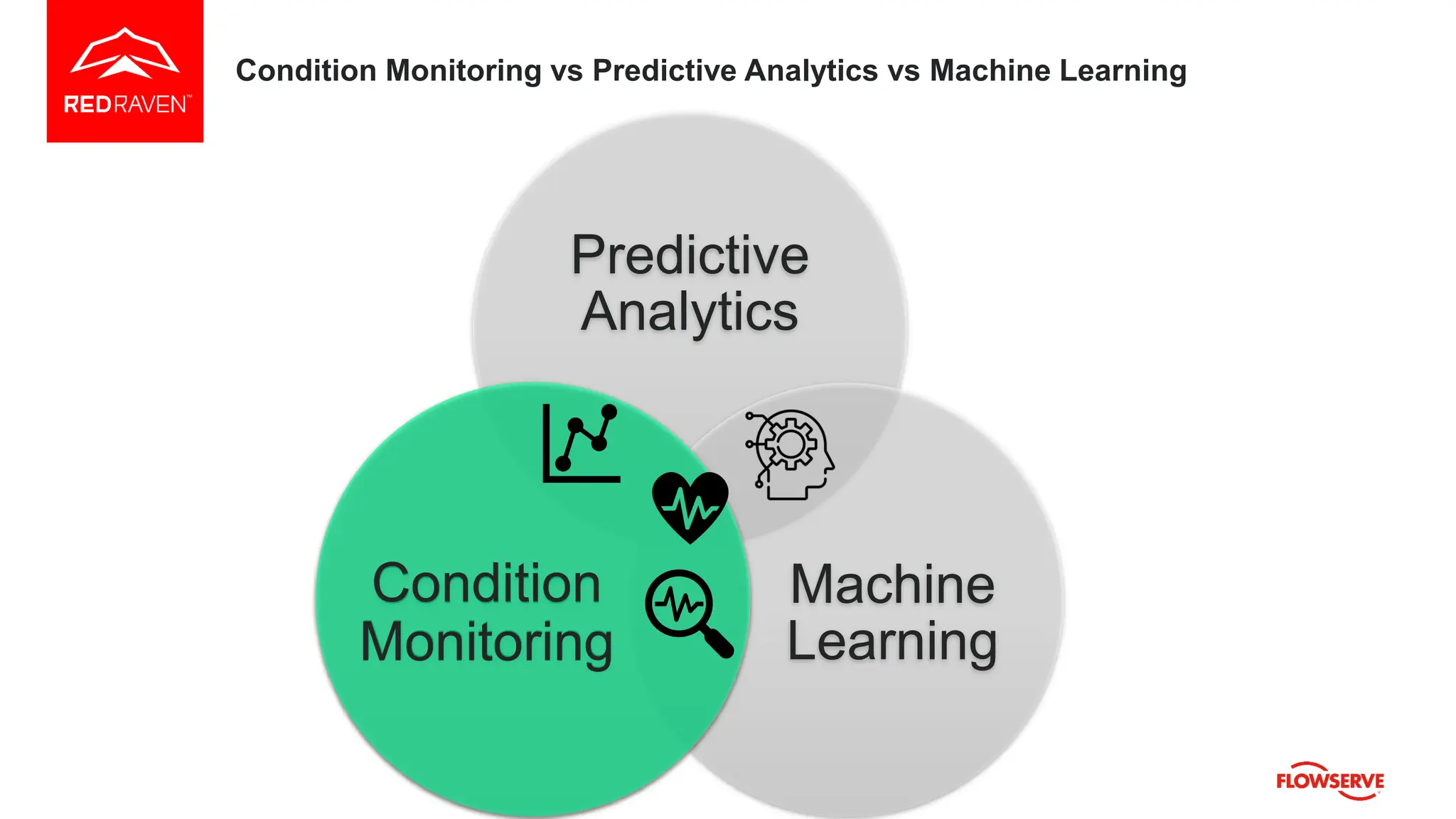

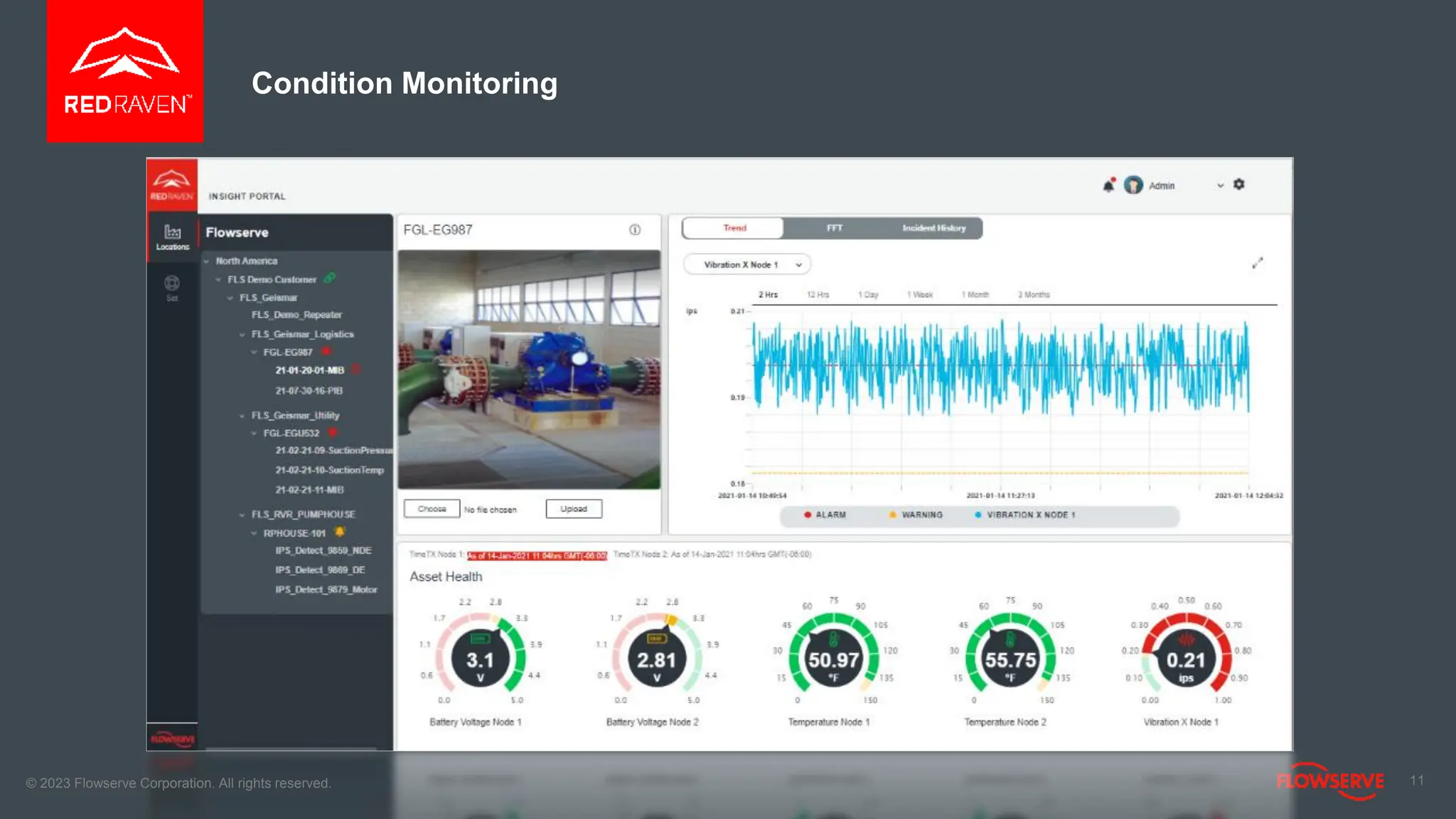

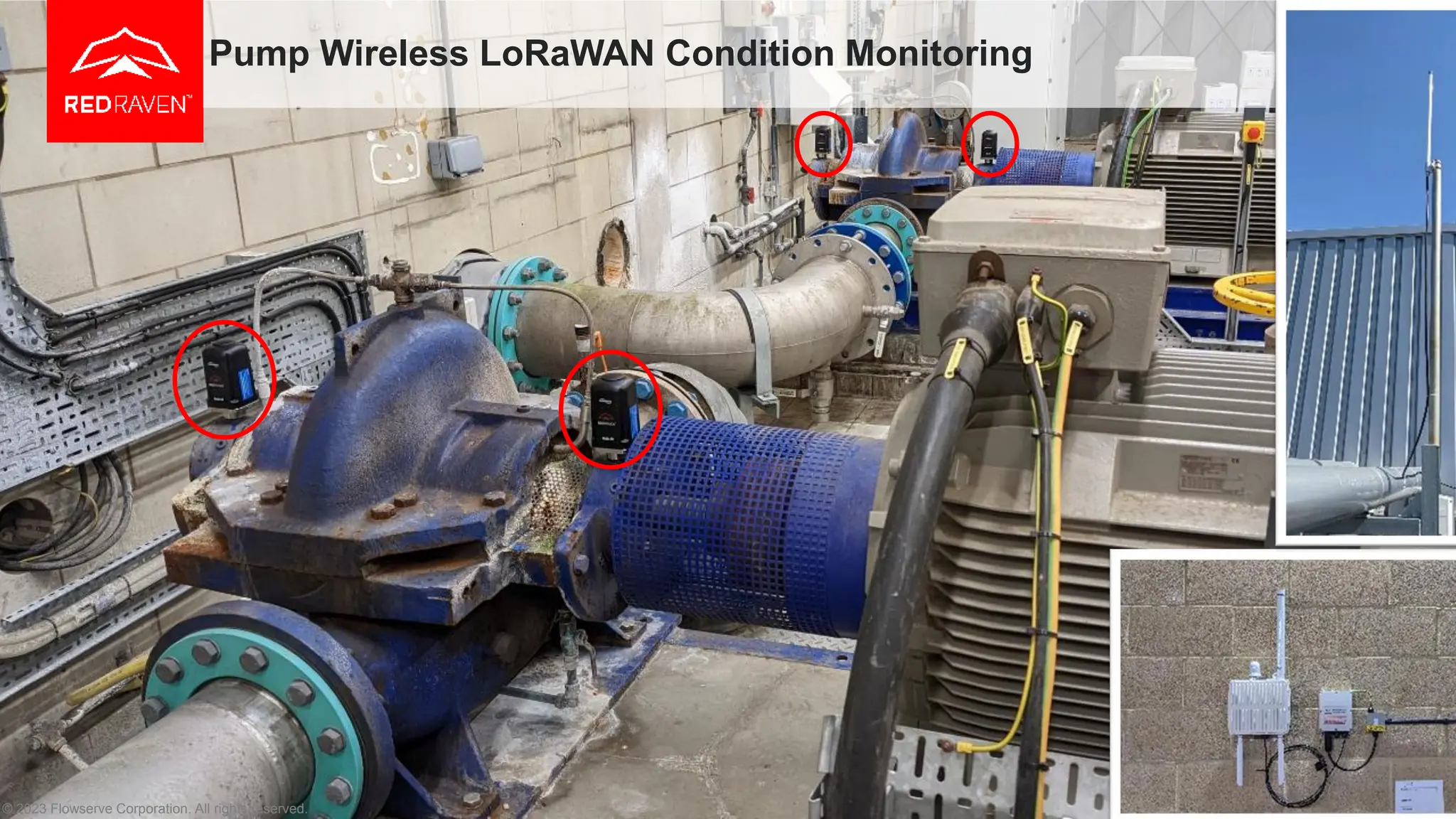

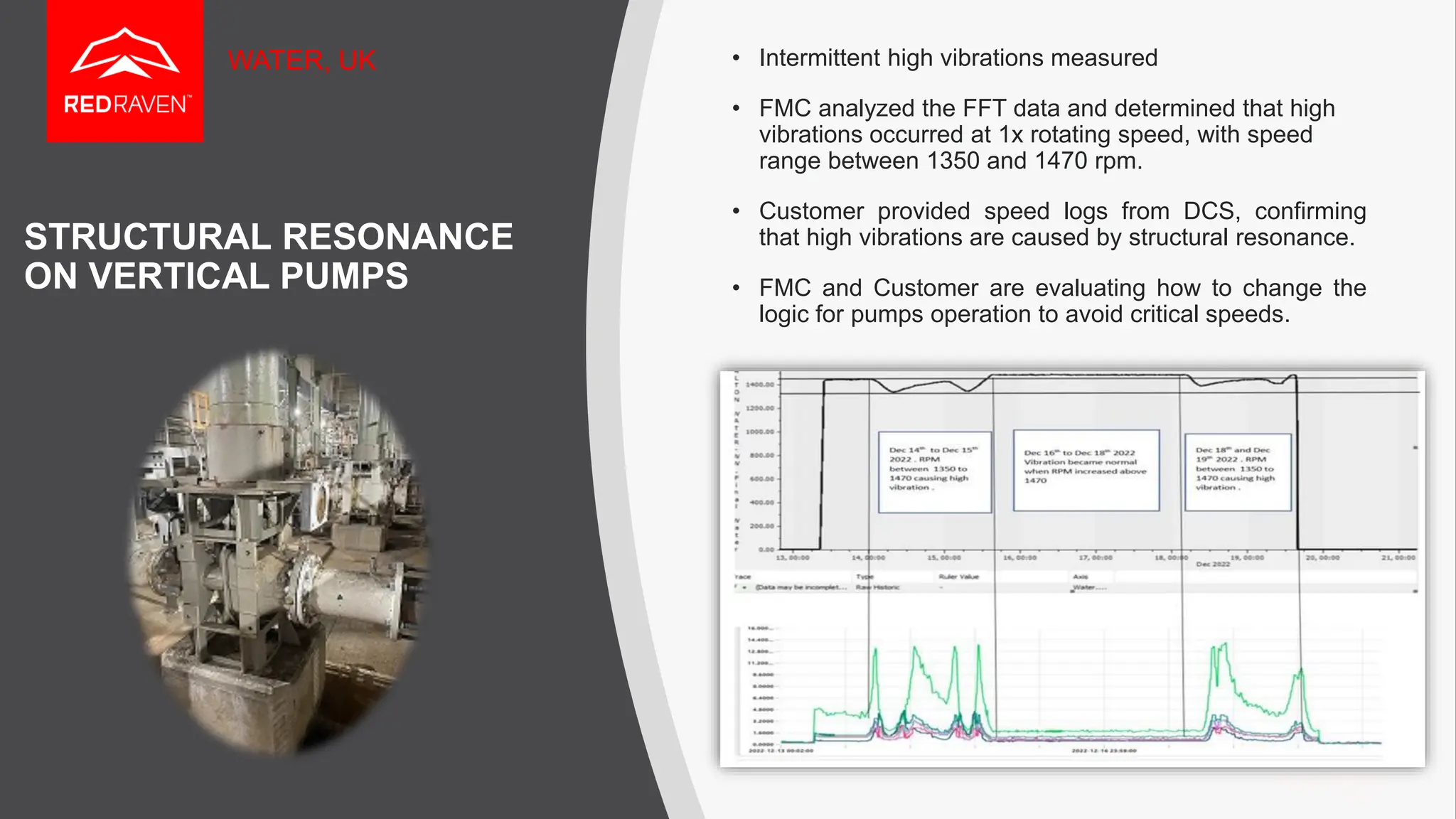

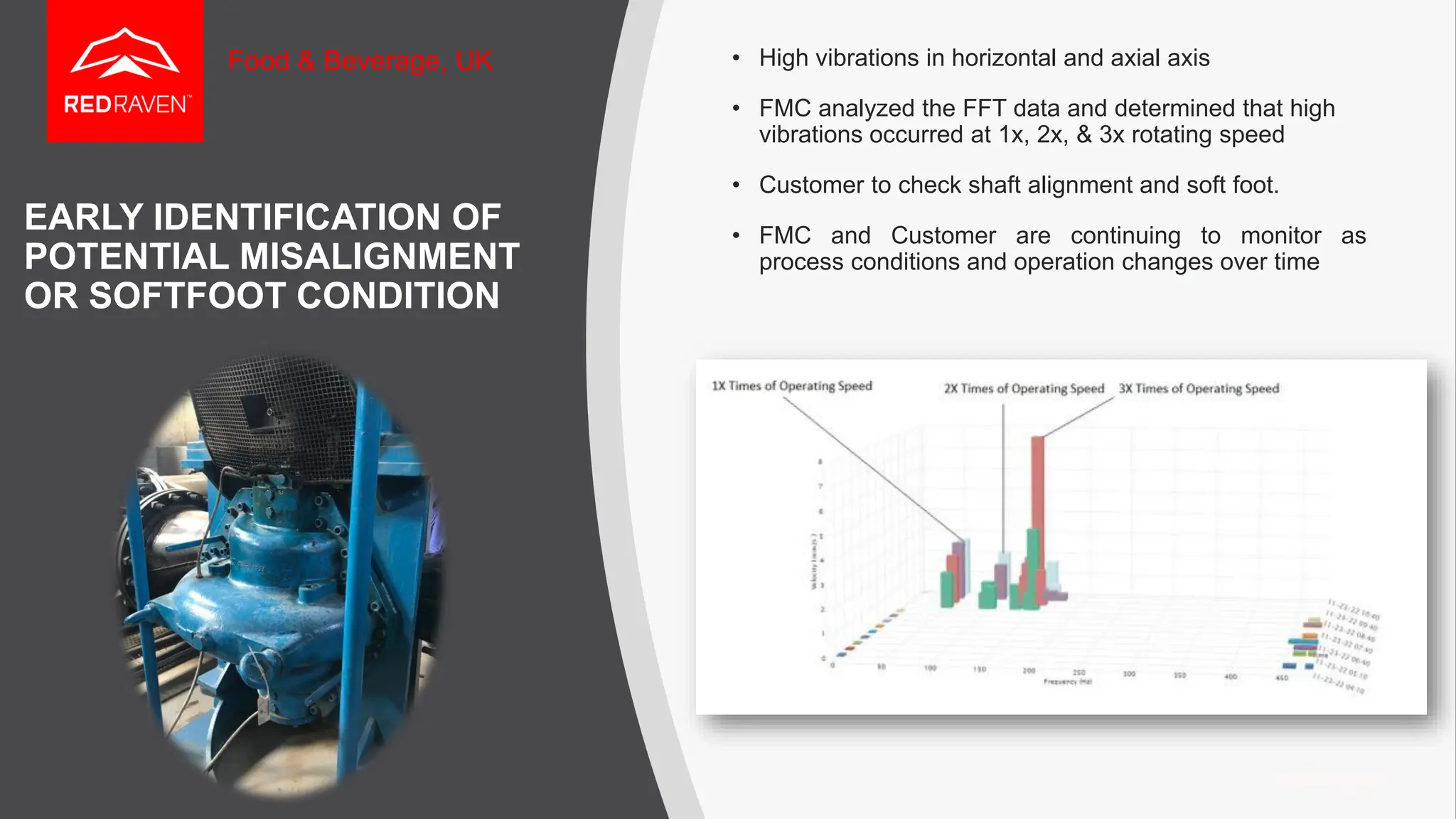

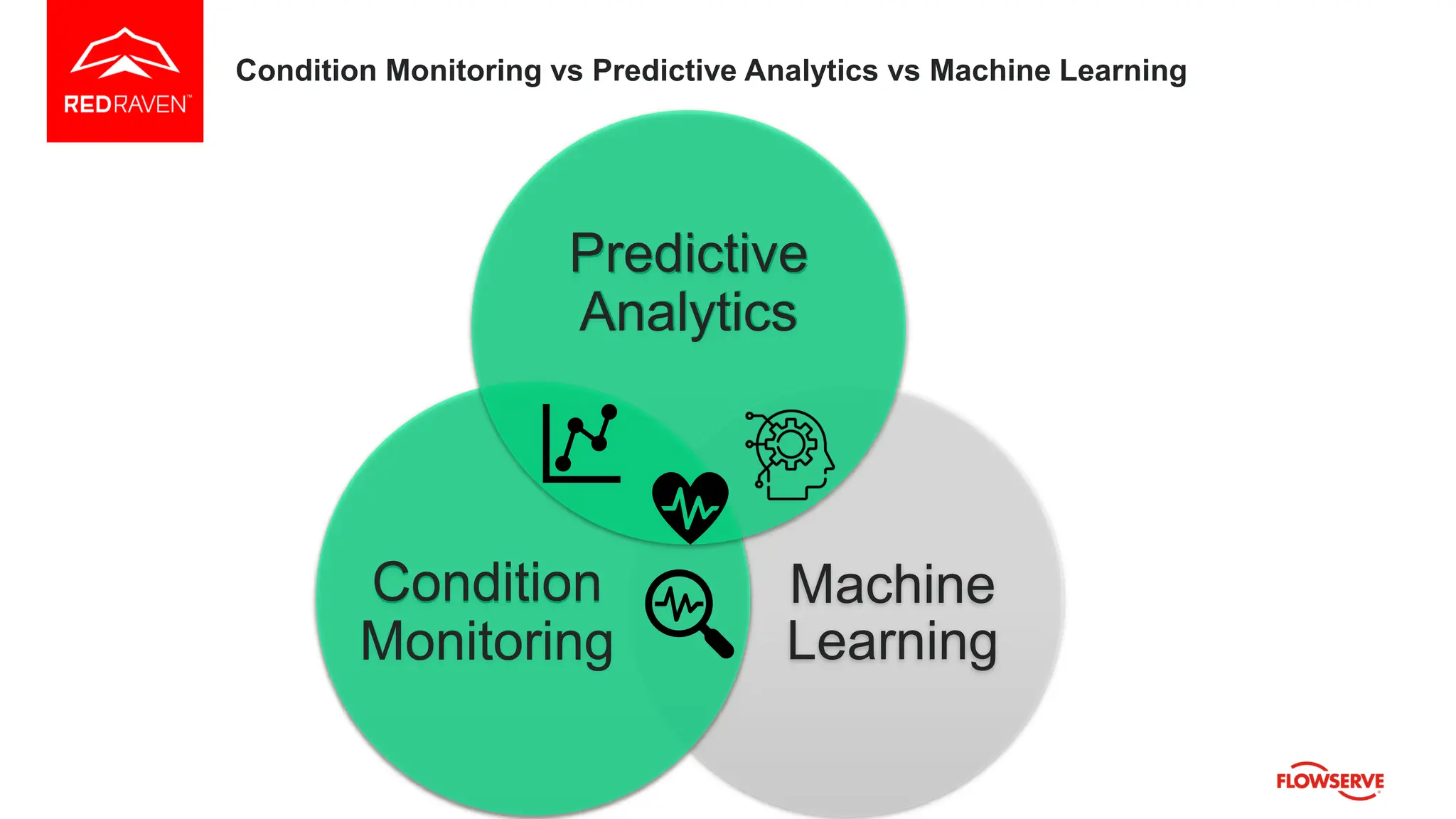

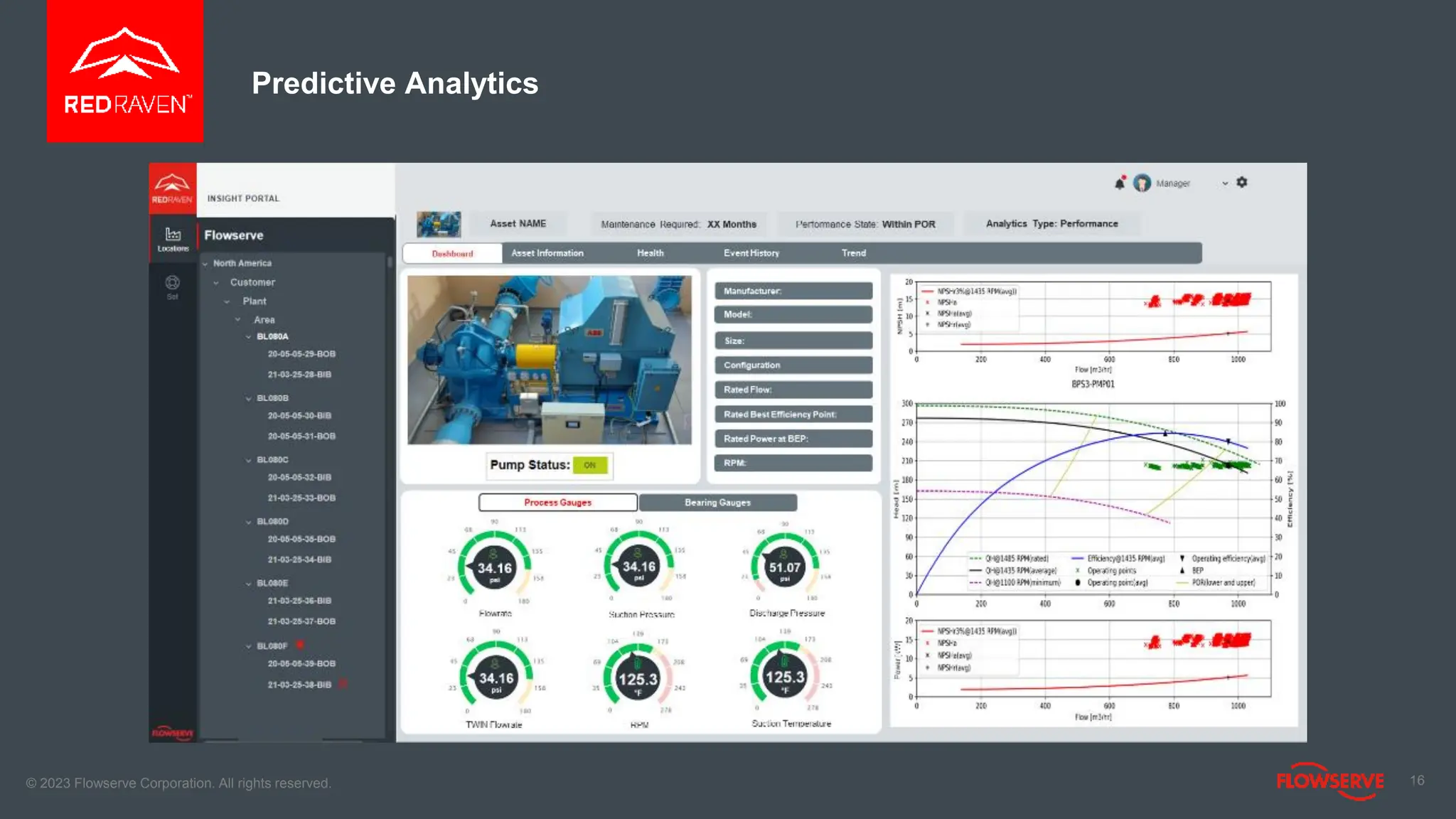

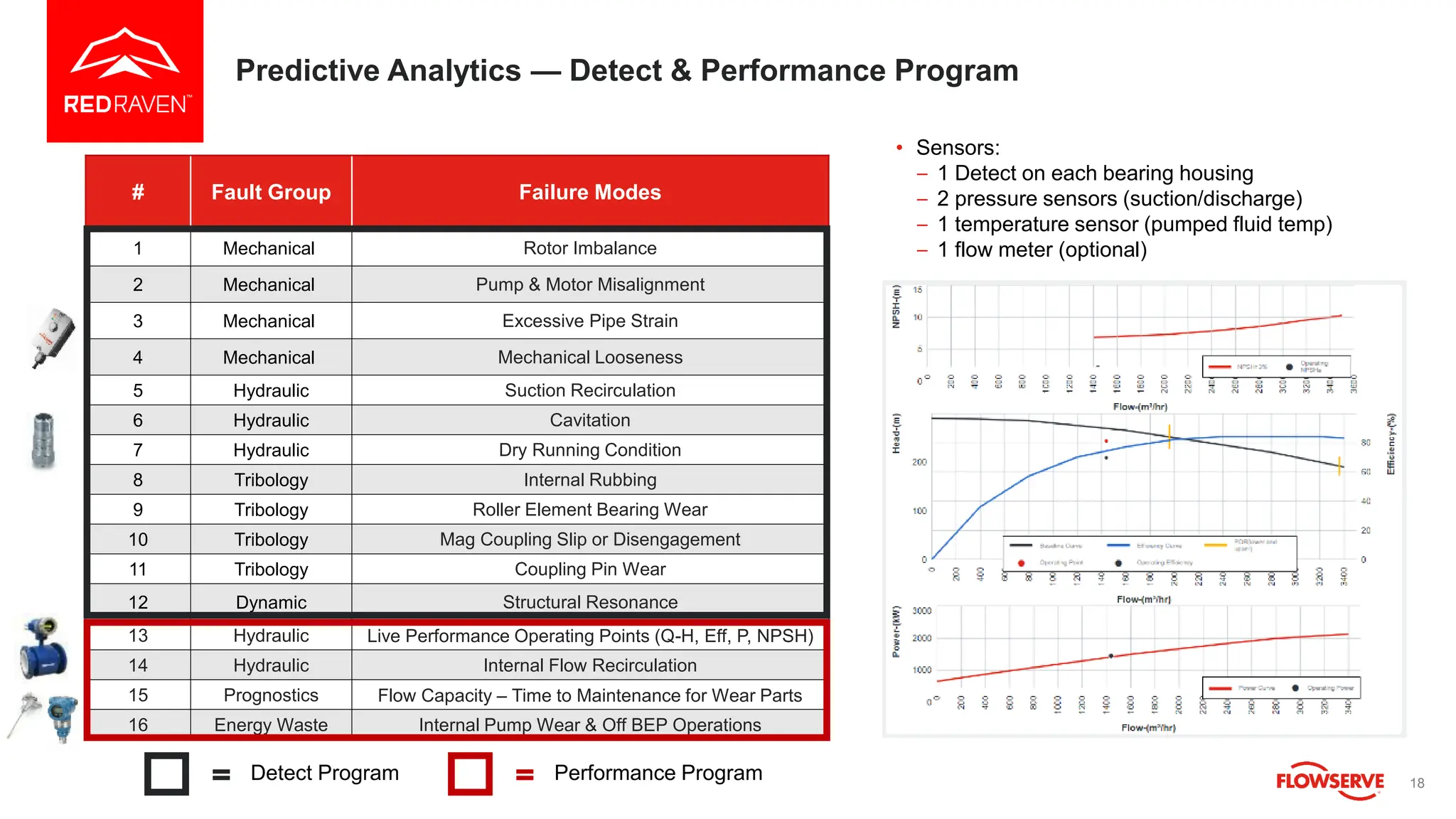

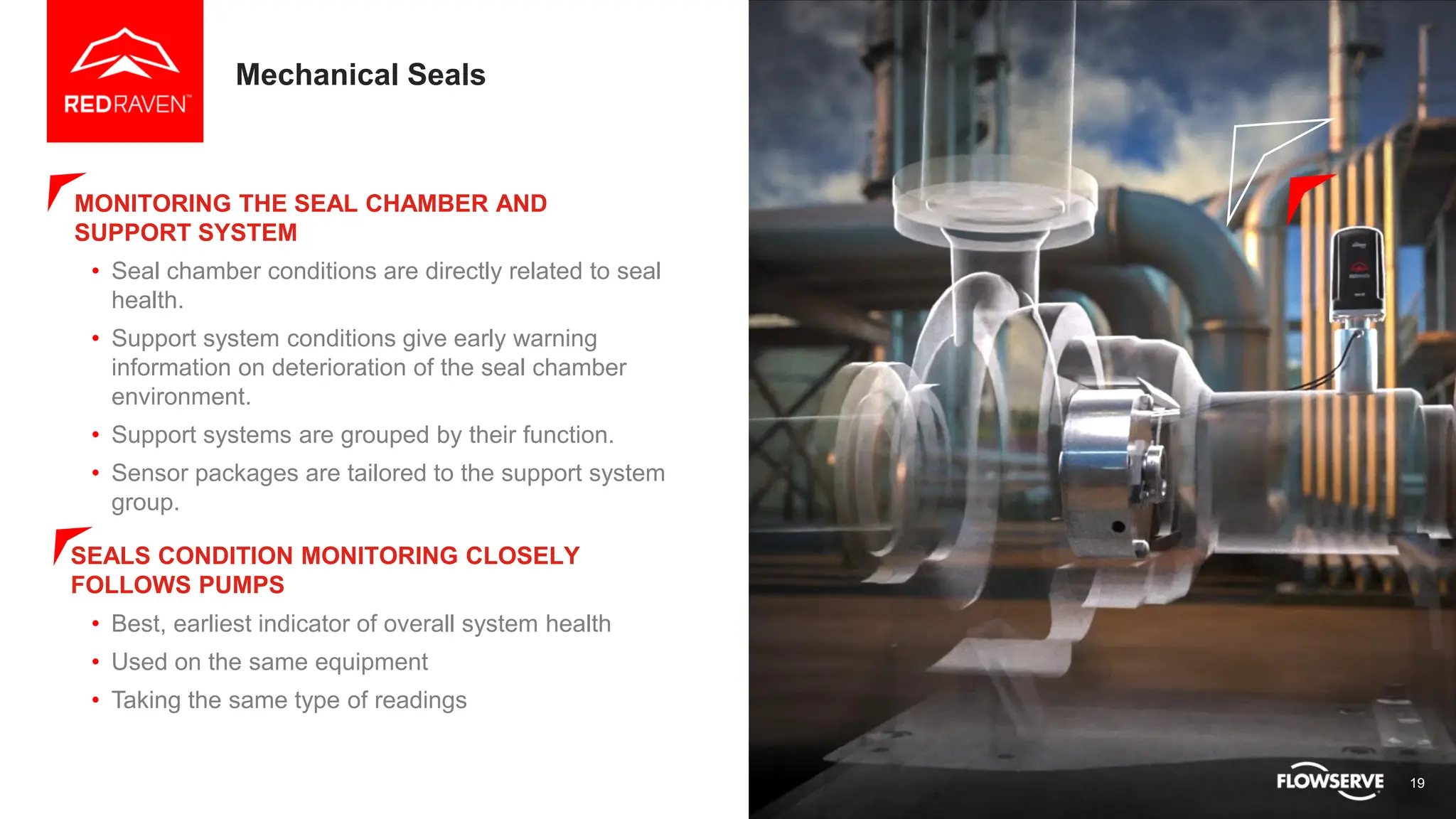

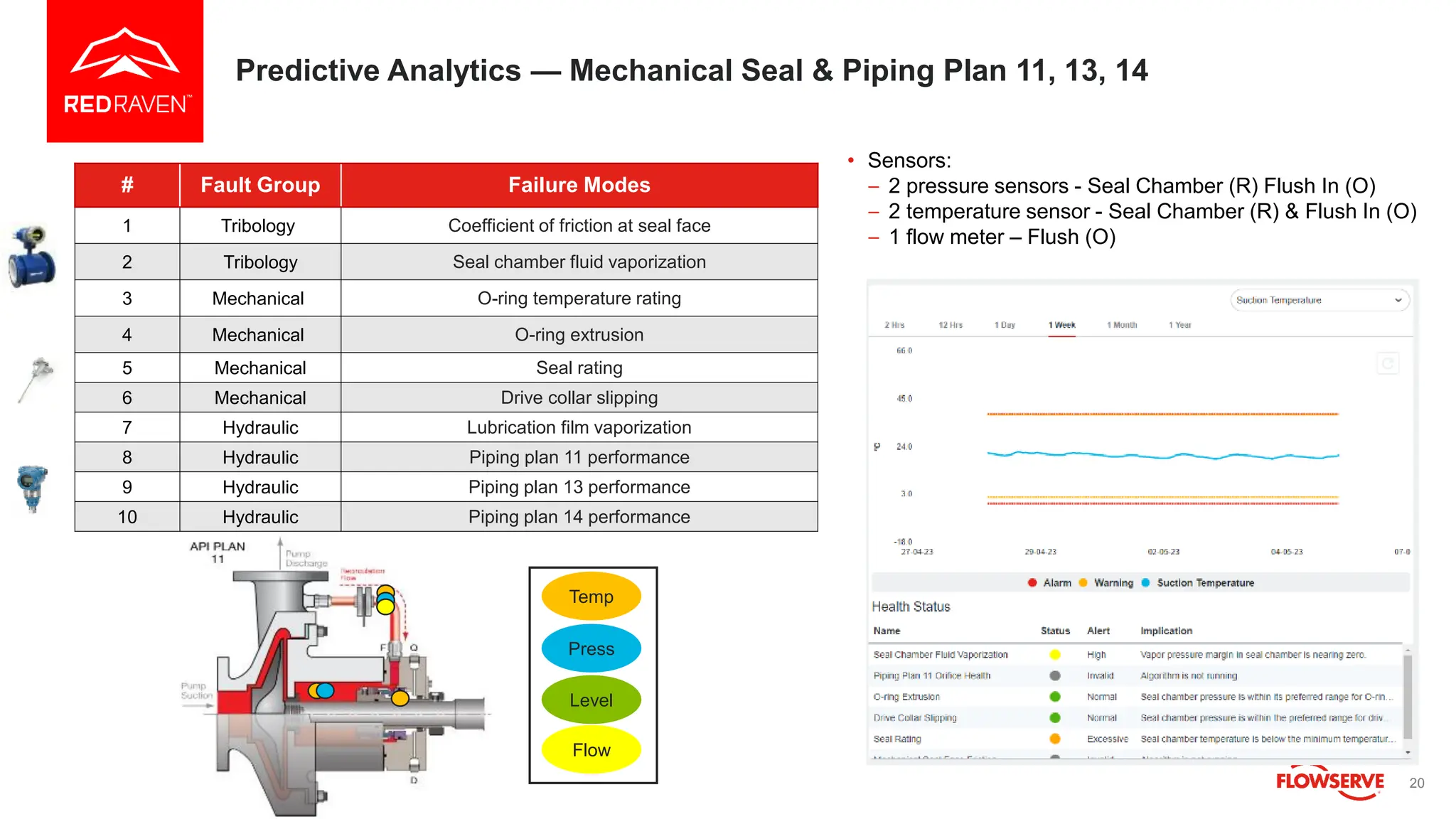

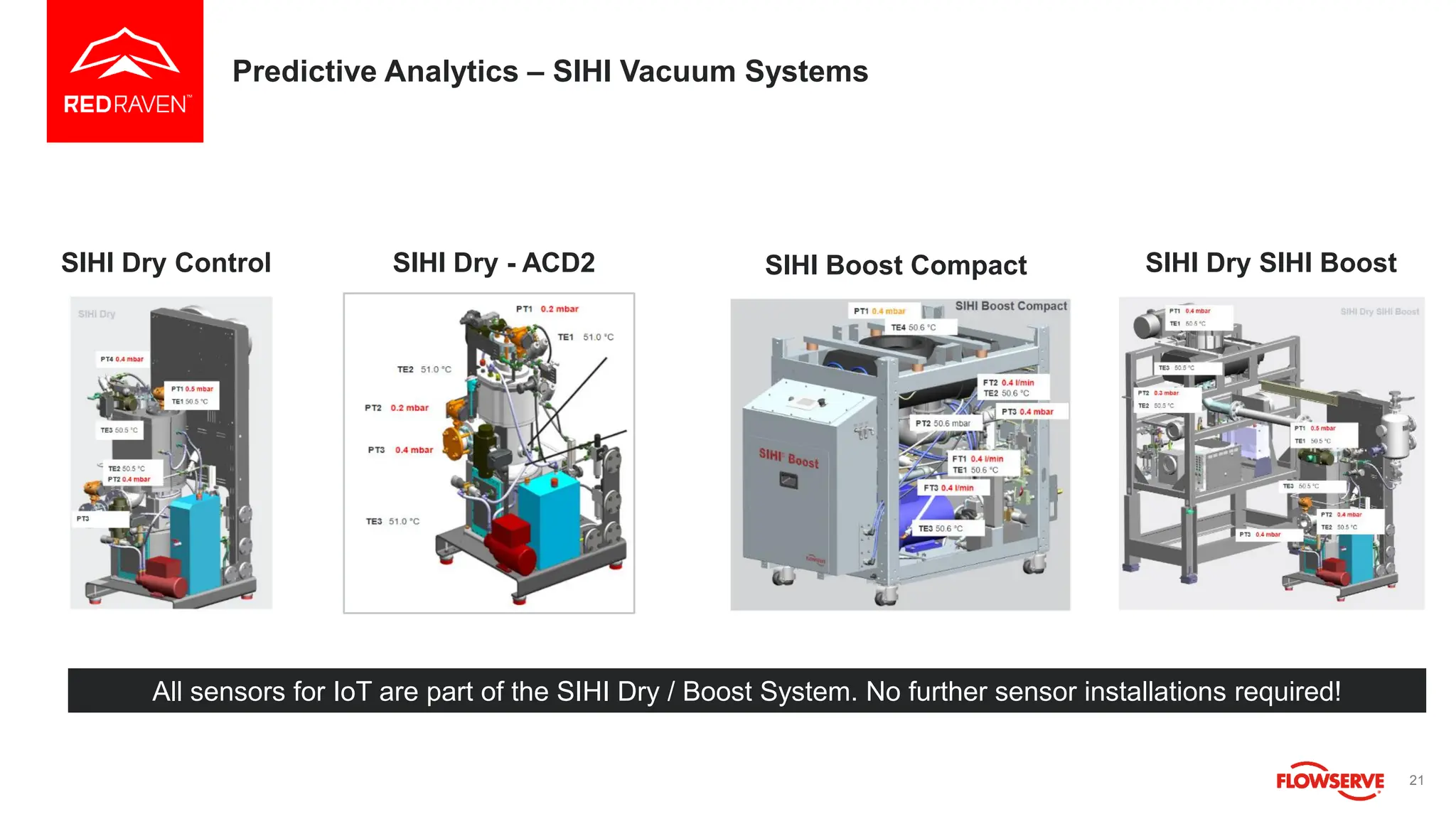

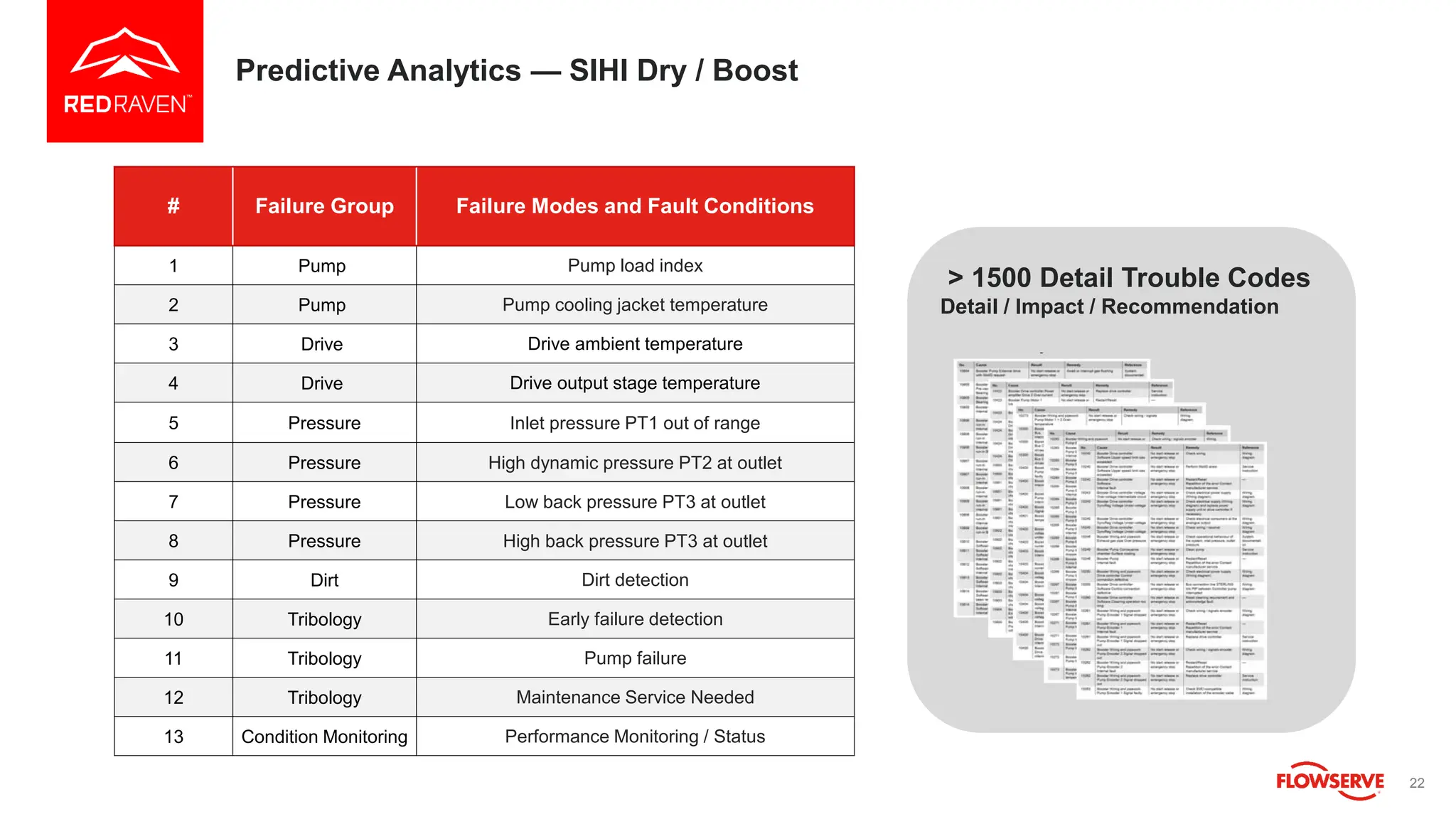

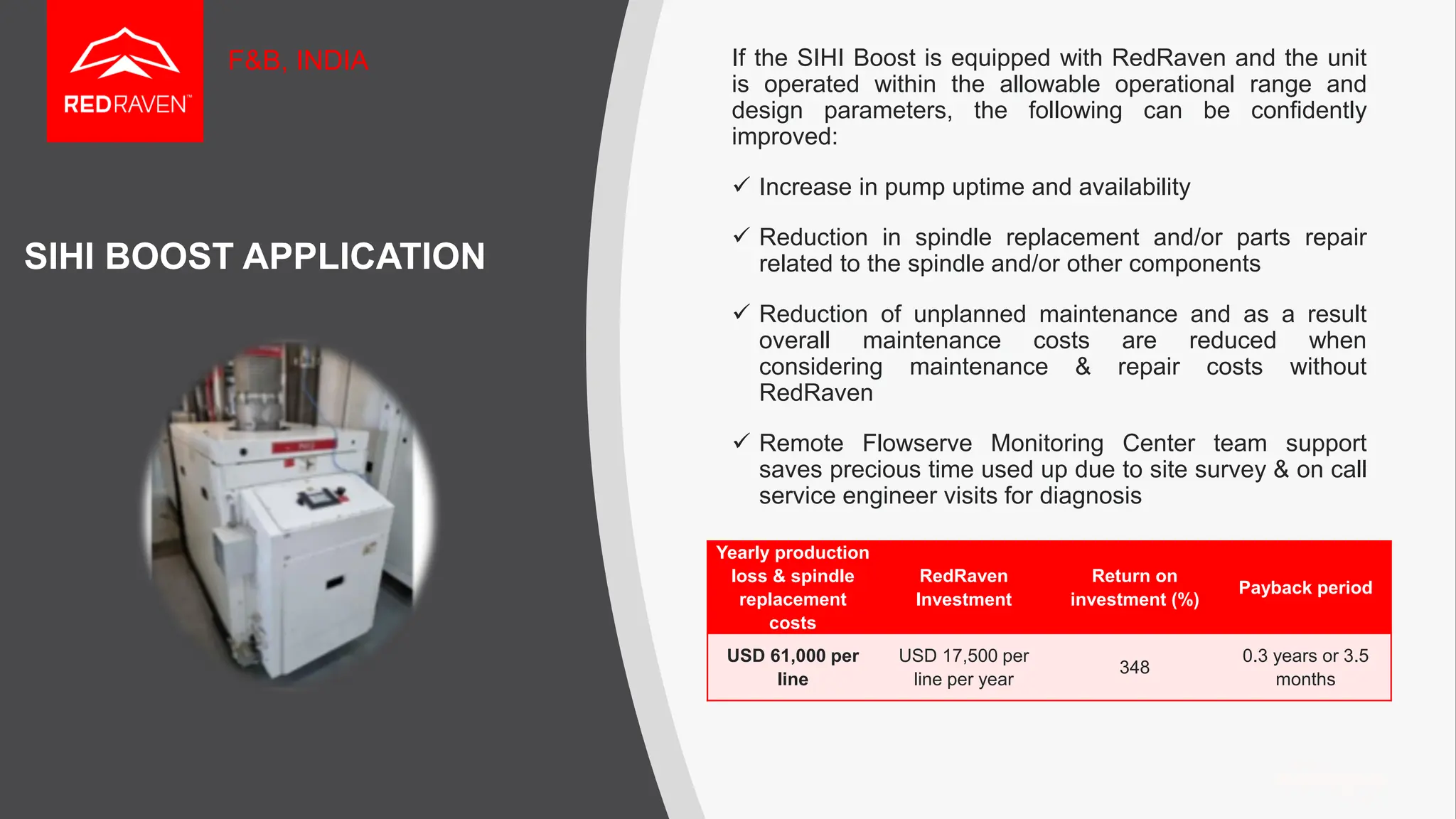

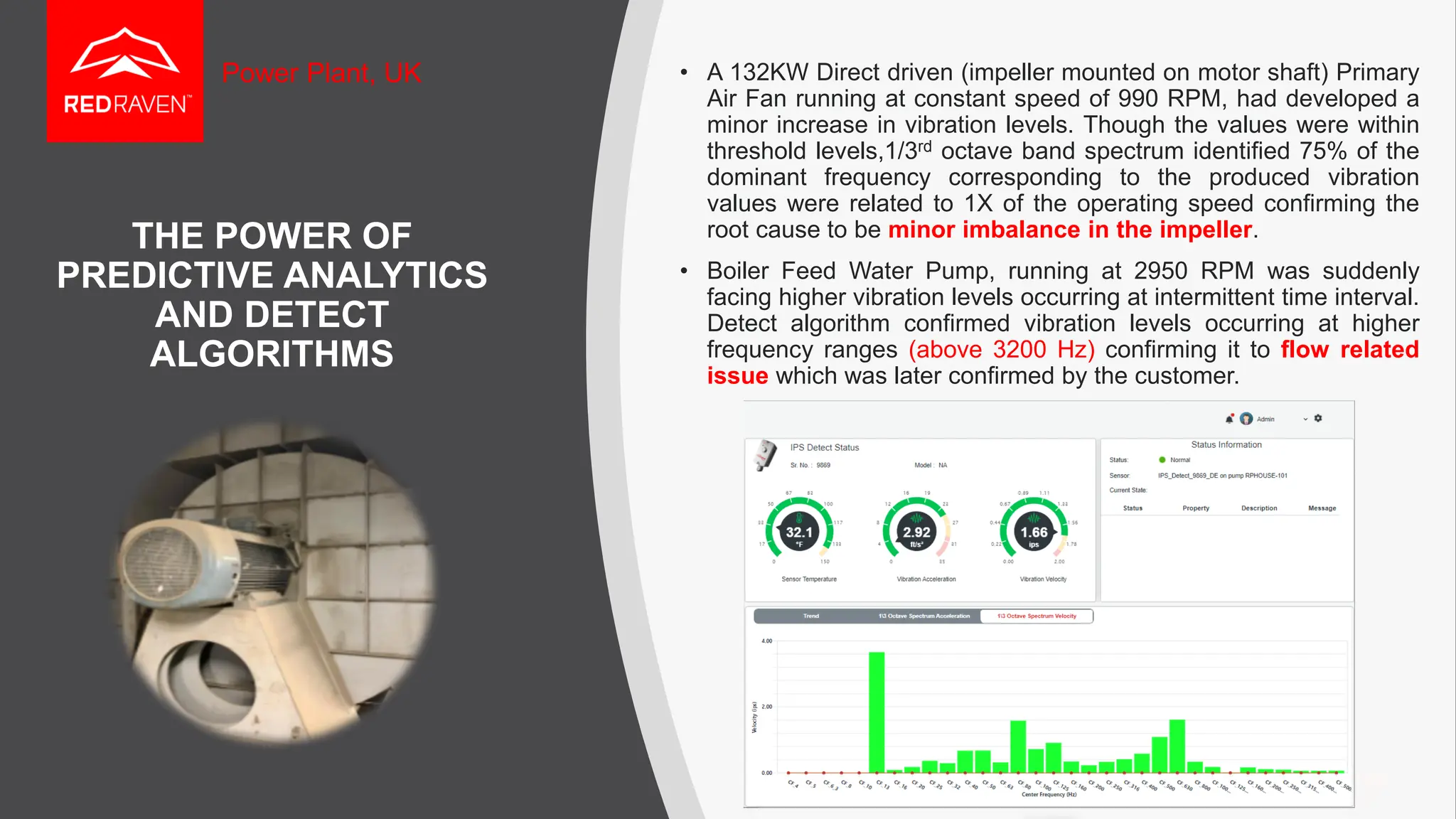

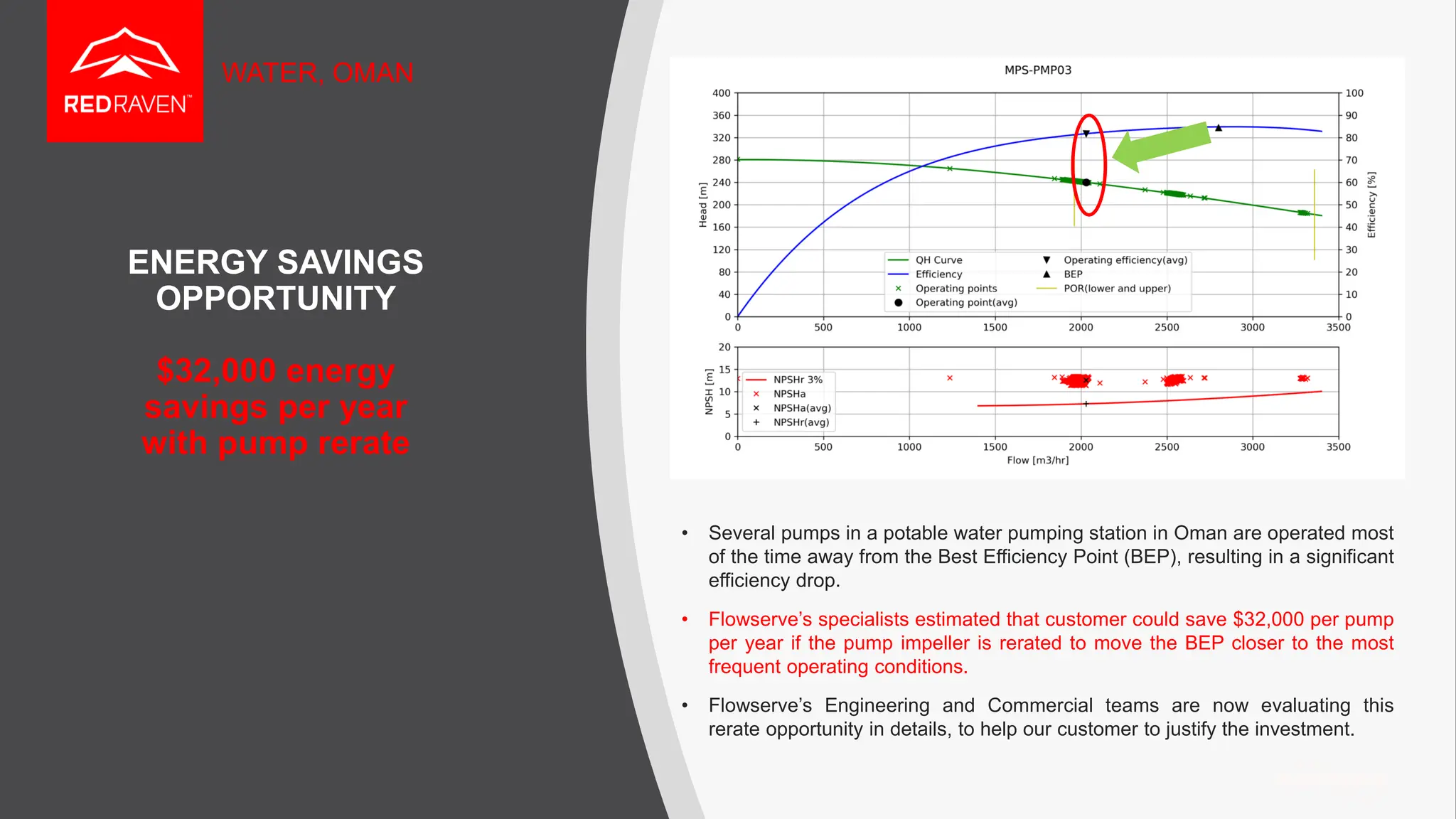

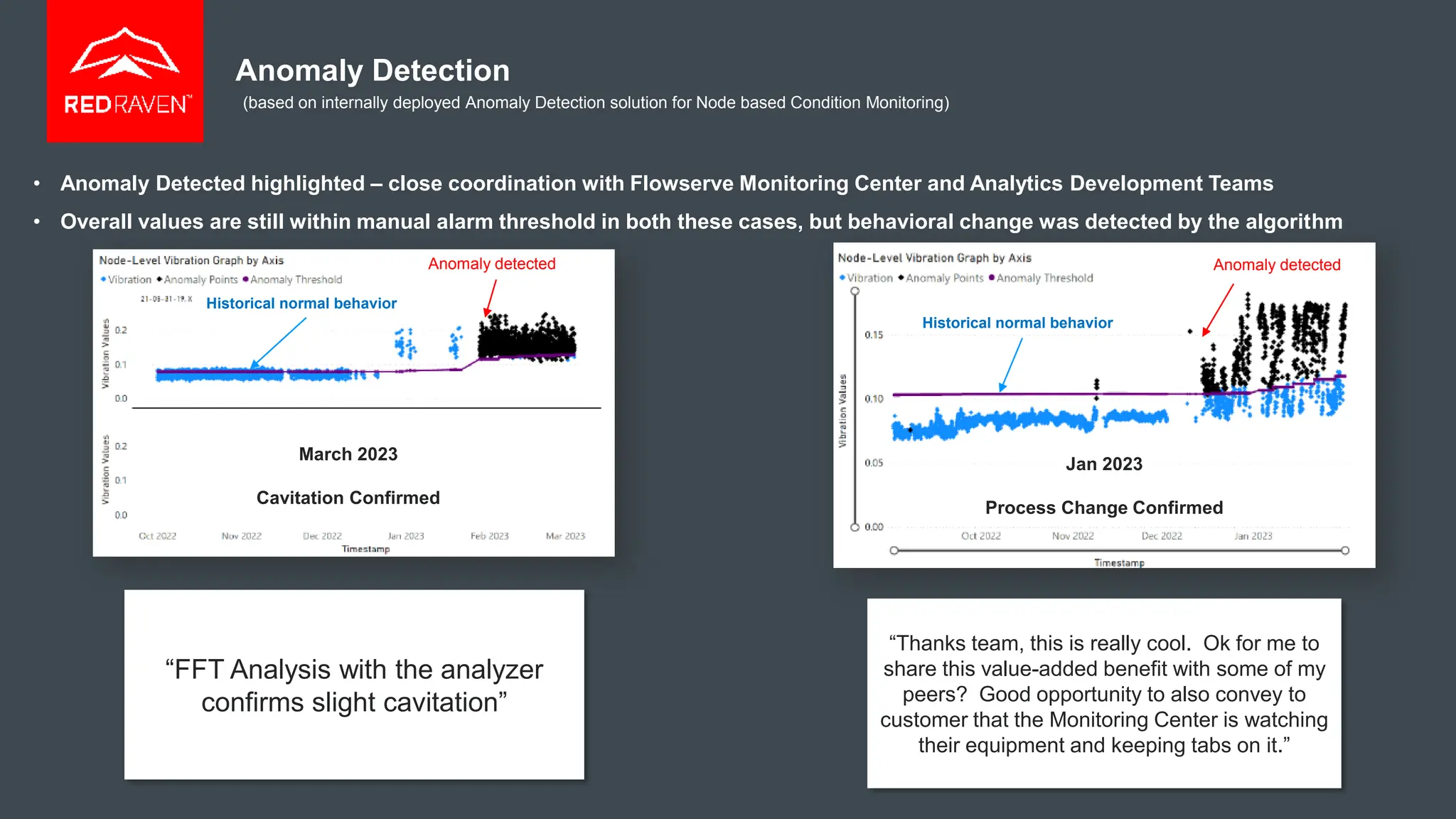

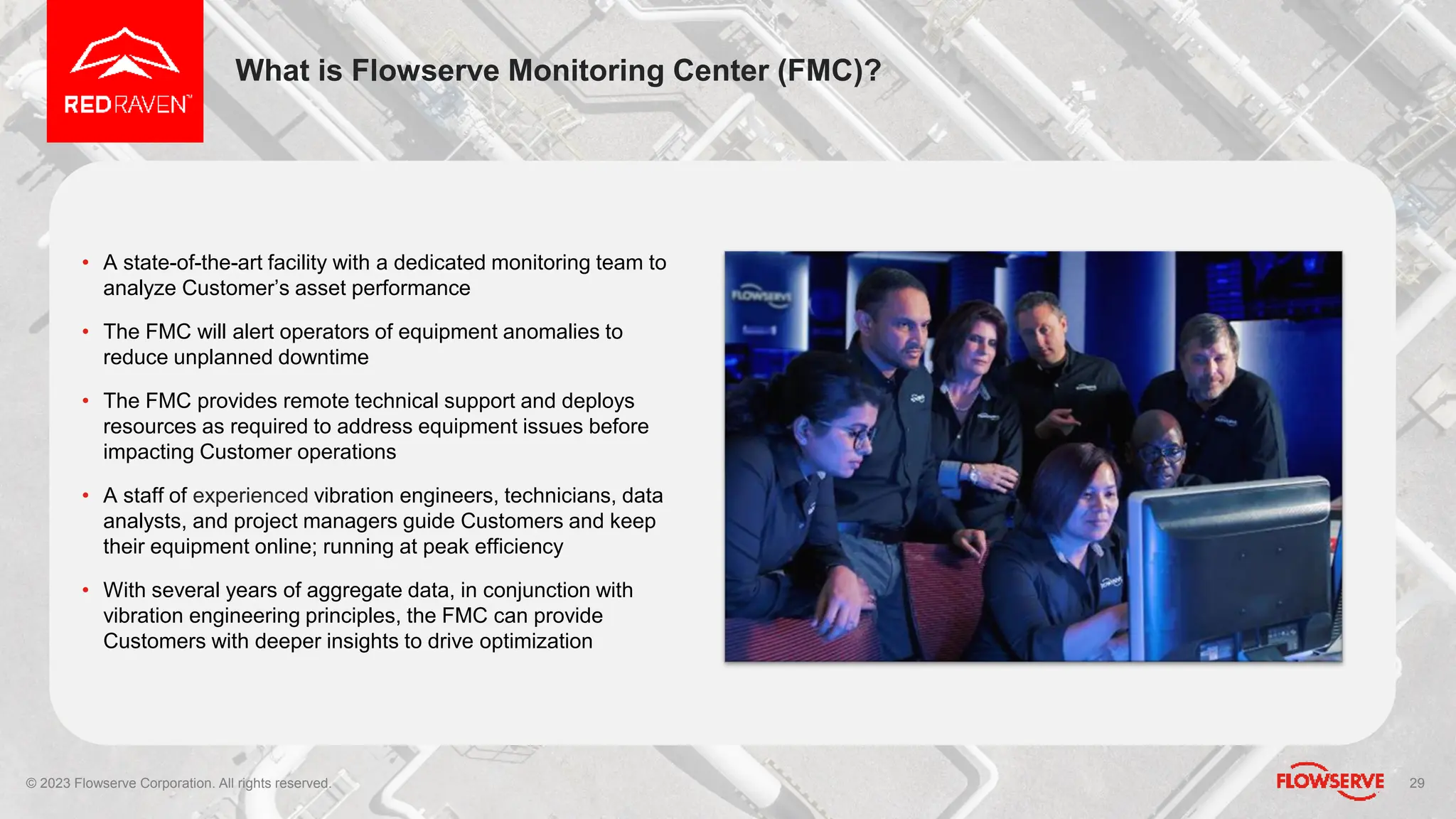

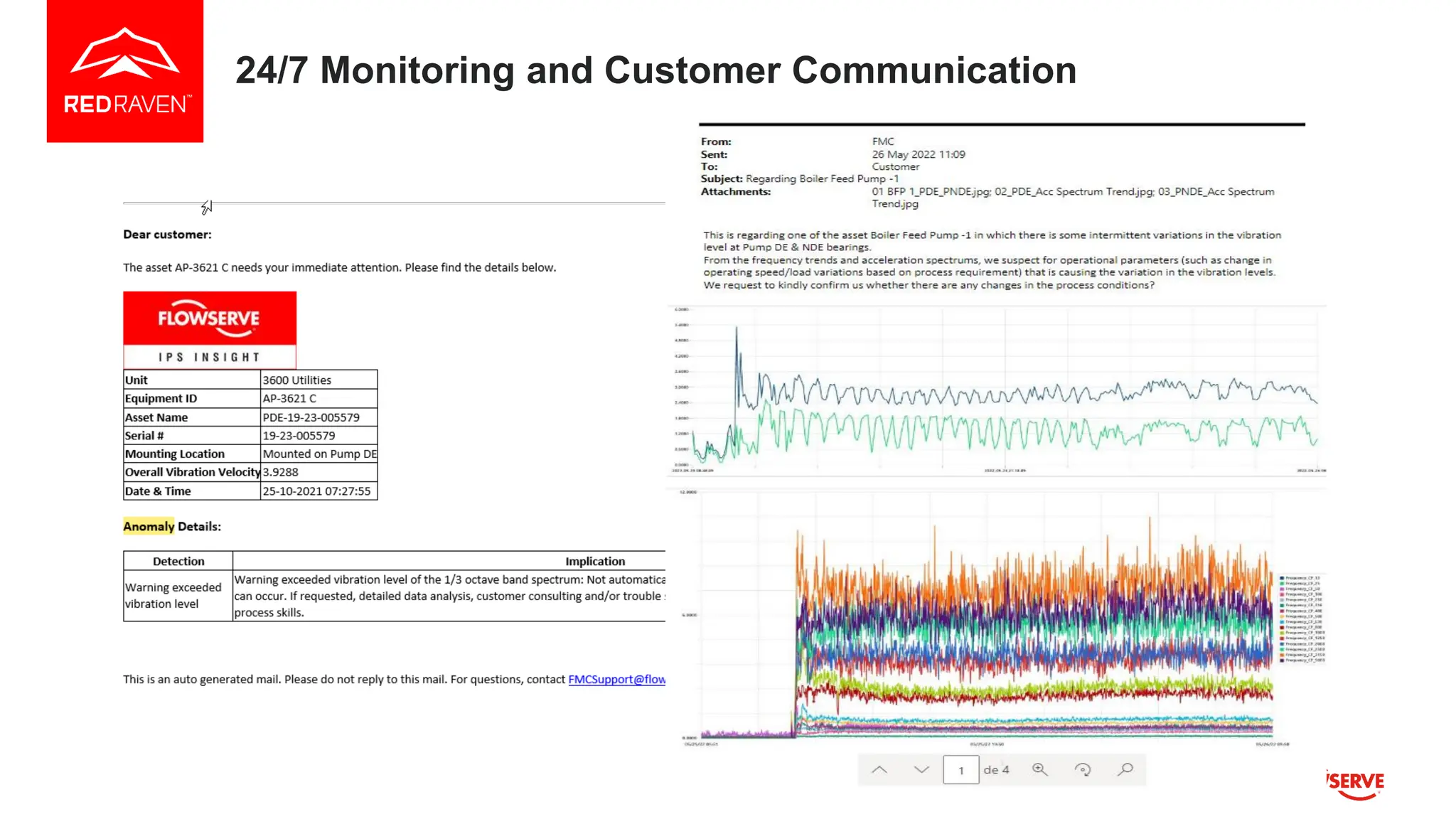

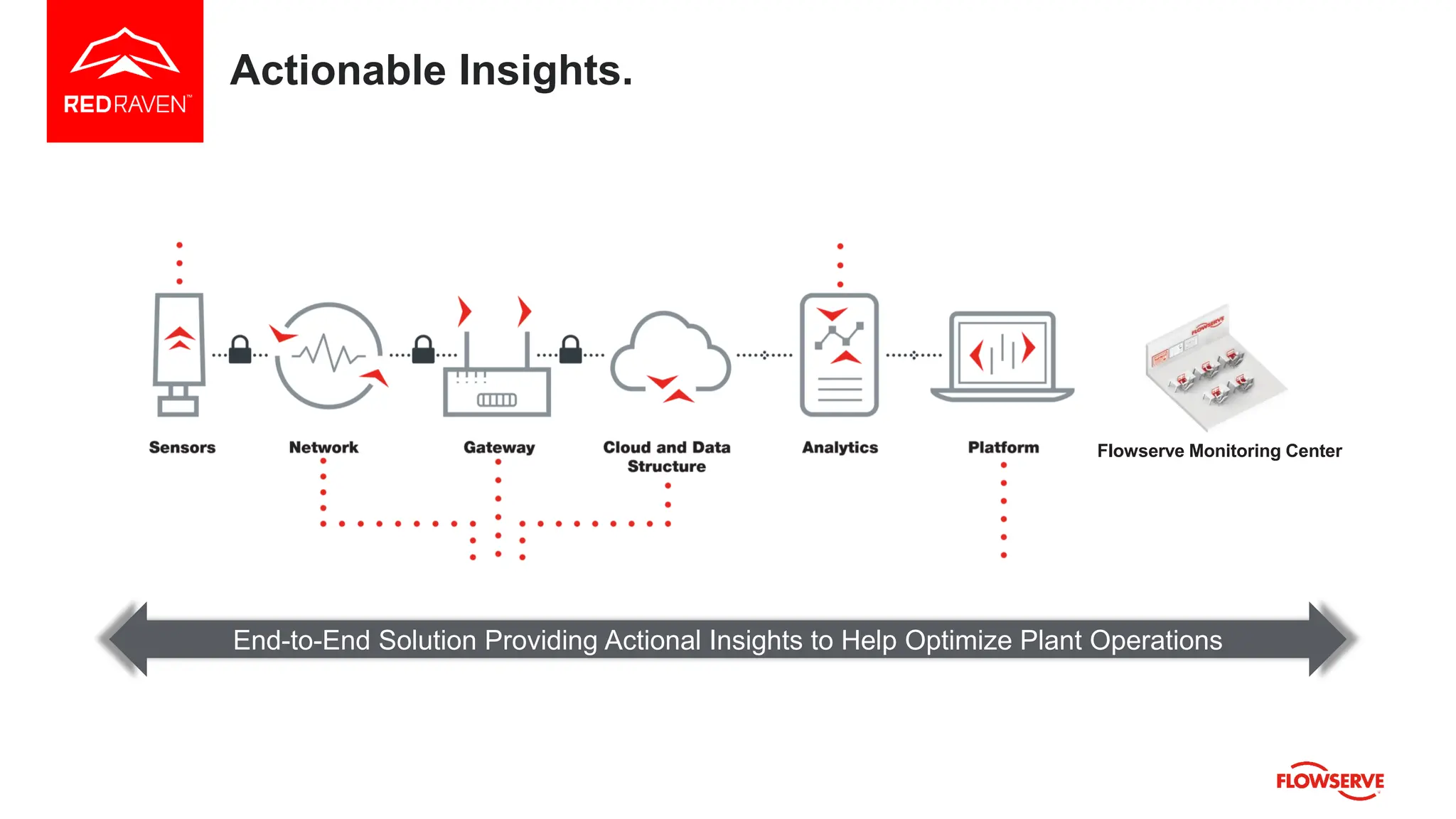

The document outlines effective strategies for plant maintenance and performance optimization for fluid control equipment, presented by Michael Zimmerman from Flowserve Corporation. It highlights the use of innovative sensors and predictive analytics to monitor equipment health, enabling organizations to reduce downtime and improve efficiency. The Flowserve Monitoring Center provides actionable insights and remote support, fostering proactive rather than reactive maintenance approaches.