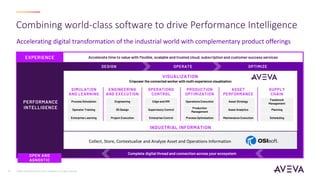

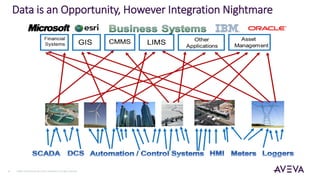

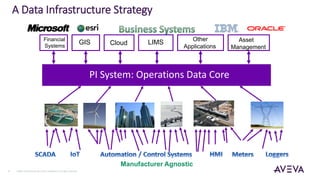

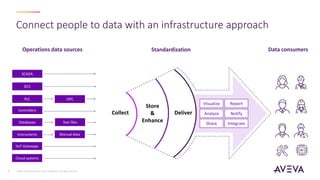

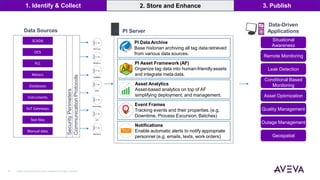

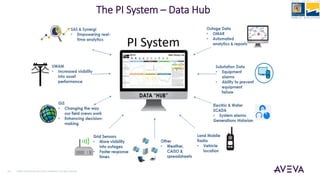

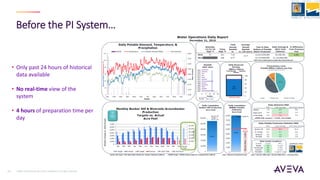

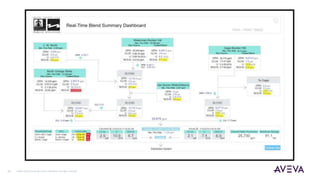

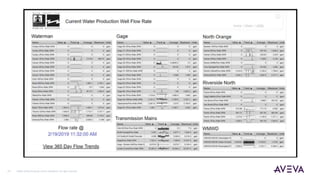

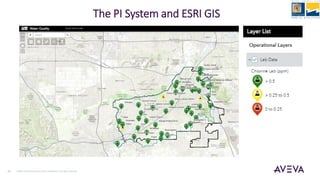

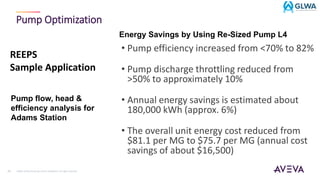

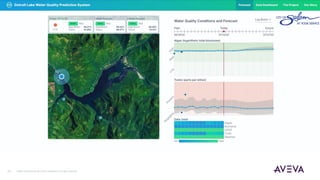

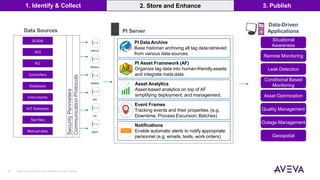

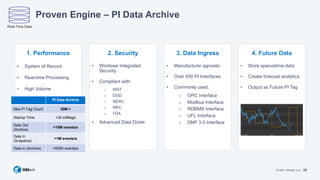

The document discusses how water utilities can leverage big data and artificial intelligence using integrated software from AVEVA and OSIsoft. It describes how their software helps water utilities improve efficiency, optimize assets, ensure safety and quality, and meet regulatory reporting requirements. The software allows utilities to collect data from various sources, store and analyze it in a centralized data hub, and gain insights to improve performance. Case studies show benefits like reducing water loss and deferred capital expenditures.