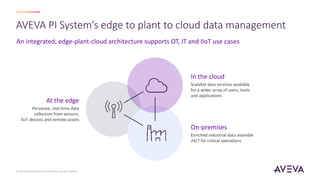

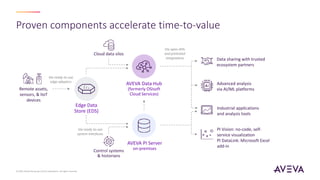

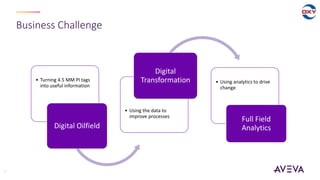

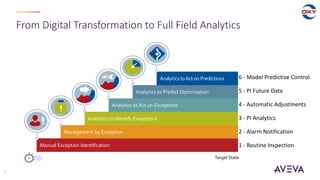

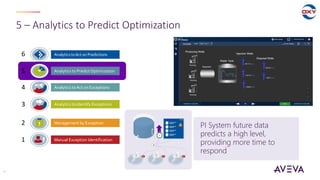

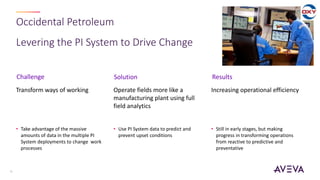

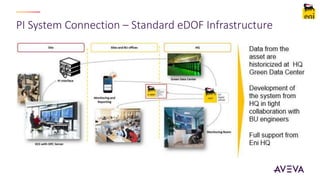

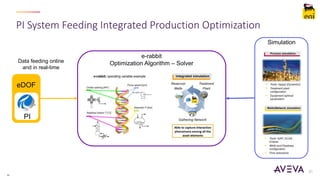

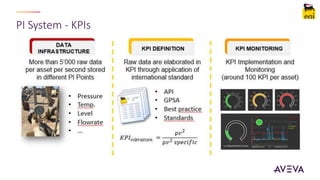

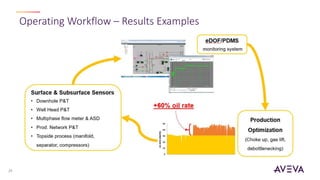

This document summarizes two case studies of companies using the PI System to optimize digital oilfield operations. The first case study describes how Occidental Petroleum used PI System data and analytics to transform their operations from reactive to predictive. The second case study outlines how Eni implemented real-time online modeling of upstream assets using PI System data fed into simulation and optimization algorithms. Both companies leveraged PI System's integrated edge-to-cloud architecture to improve efficiency and reduce costs through predictive analytics.