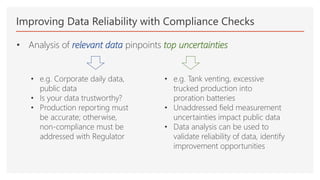

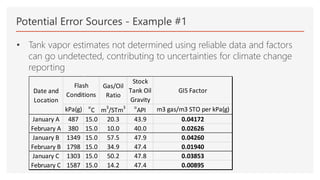

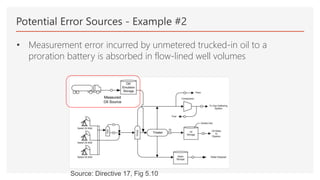

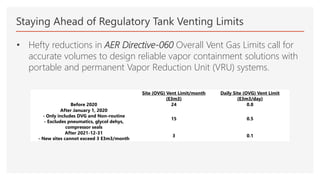

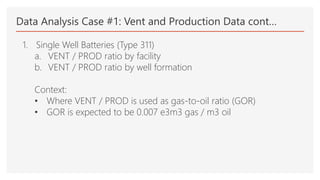

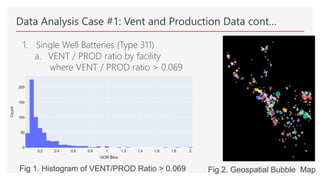

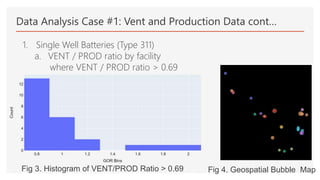

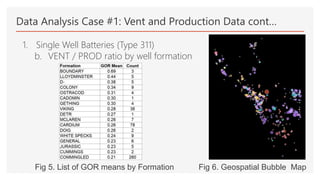

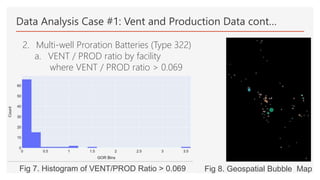

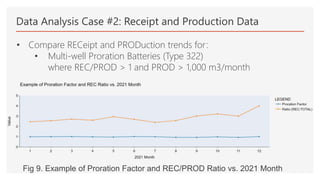

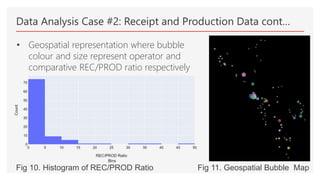

The document discusses using data analysis to improve compliance and identify potential errors in measurement and reporting. It provides examples of analyzing vent and production data from single well and multi-well sites to identify outliers. Another example analyzes receipt and production data from multi-well sites. The analysis can identify facilities with high vent-to-production or receipt-to-production ratios that may indicate errors. This helps improve data reliability and address non-compliance before it becomes an issue.