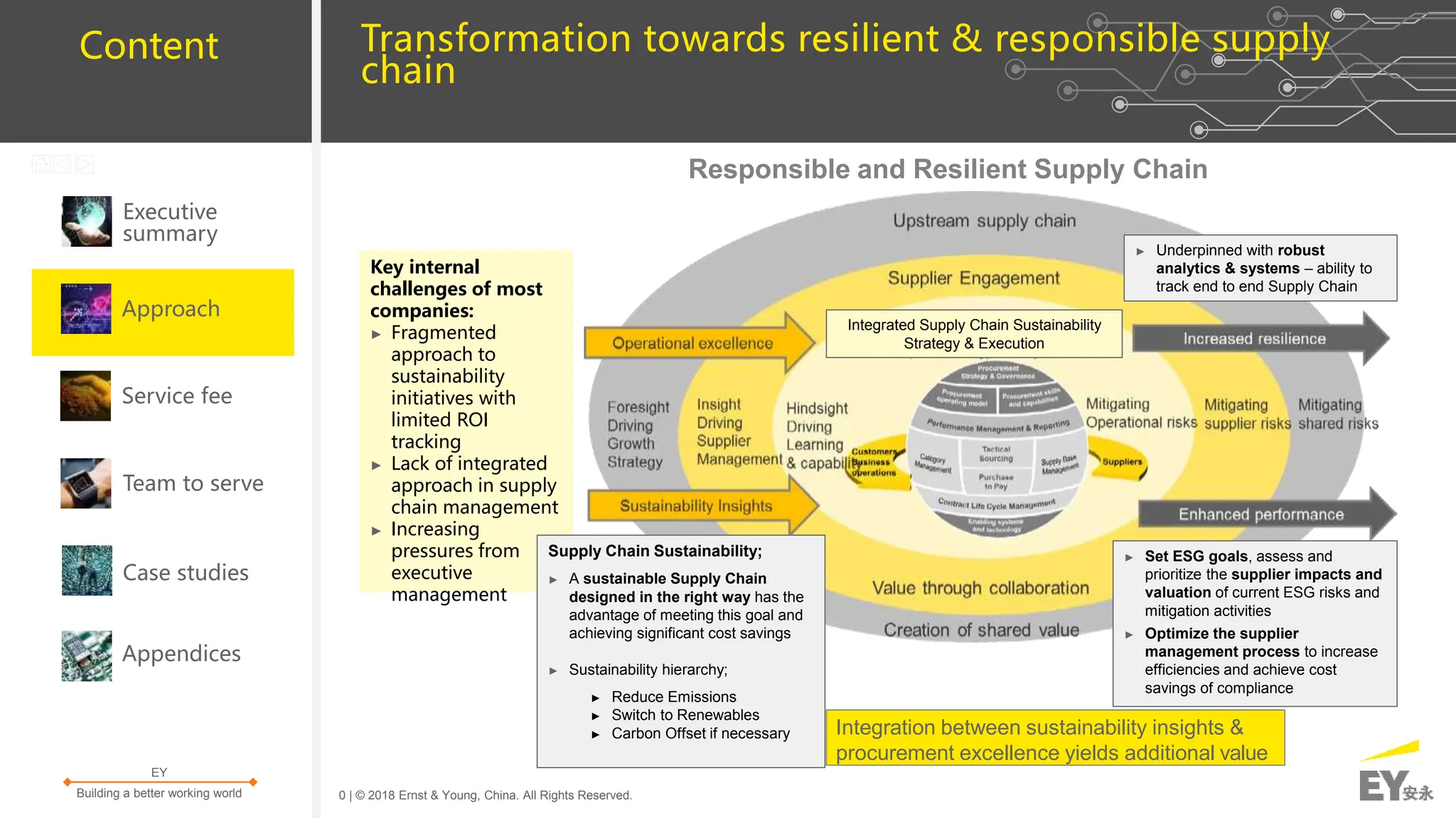

The document discusses the importance of integrating sustainability into supply chain management to create a responsible and resilient system that can yield cost savings and improve efficiency. It highlights key challenges faced by companies, such as fragmented sustainability initiatives and a lack of cohesive strategies, while emphasizing the need for robust analytics to track and manage sustainability risks effectively. The proposed approach involves setting ESG goals, enhancing supplier management, and leveraging data analytics for continuous improvement across the supply chain.