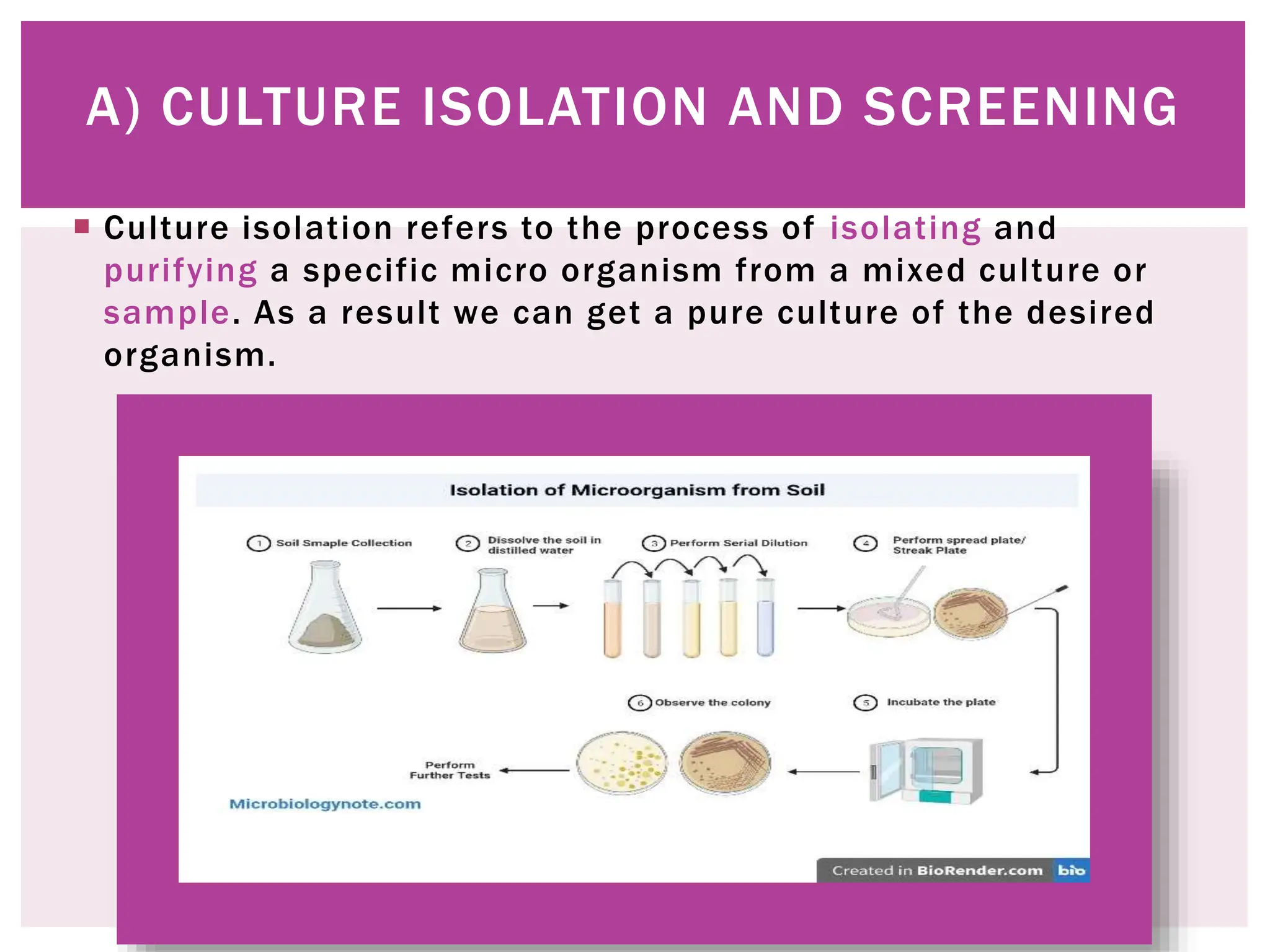

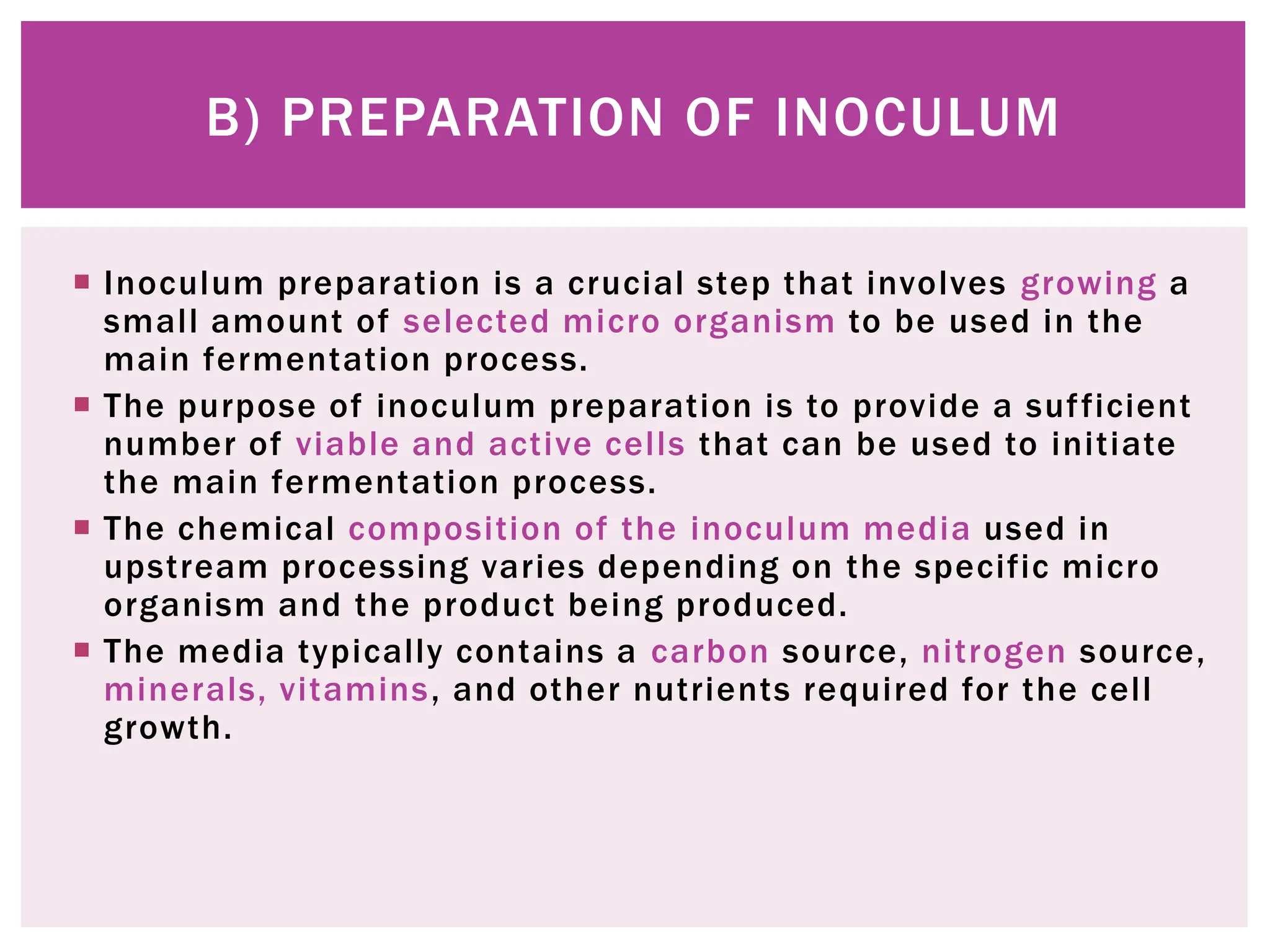

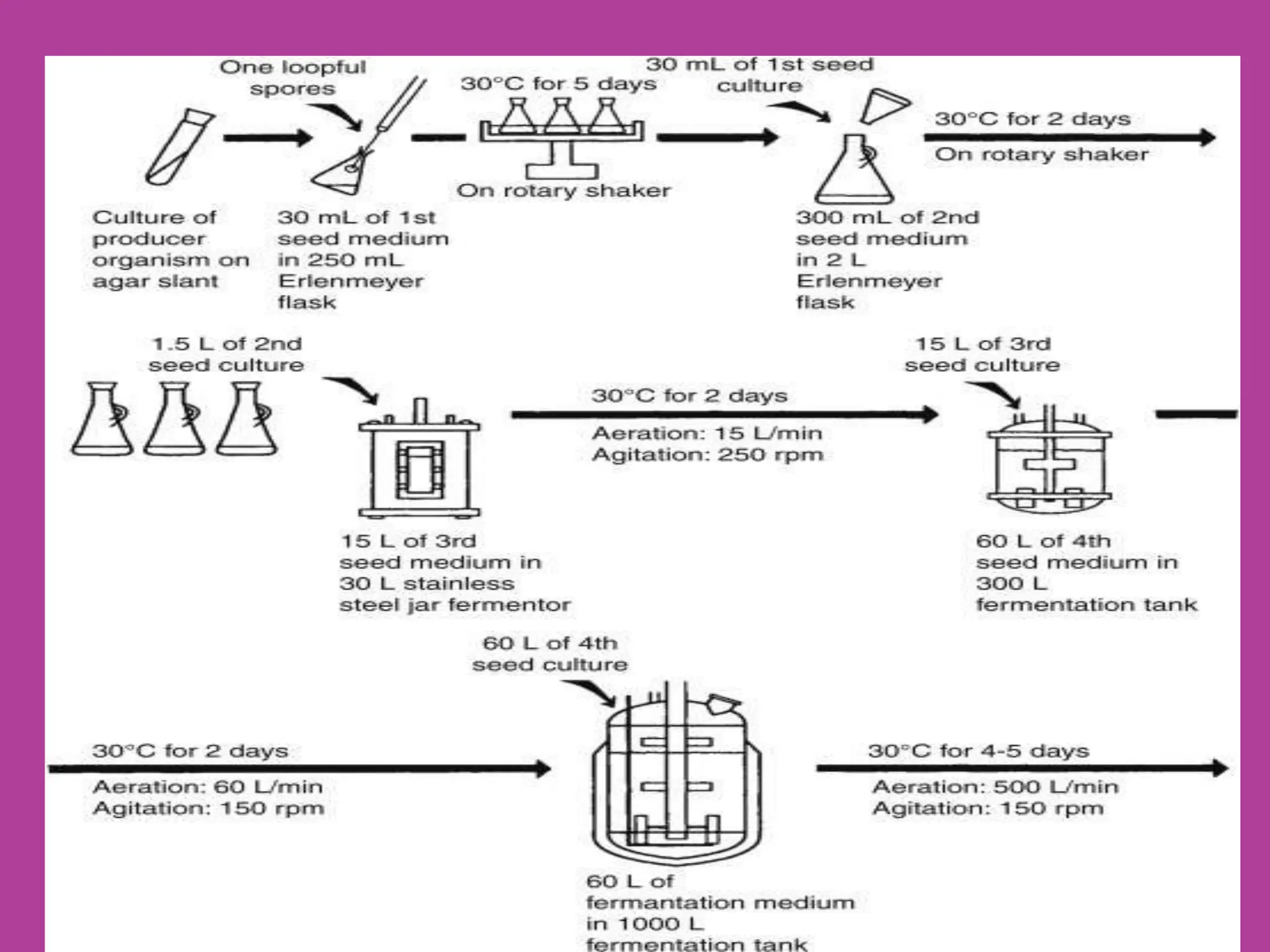

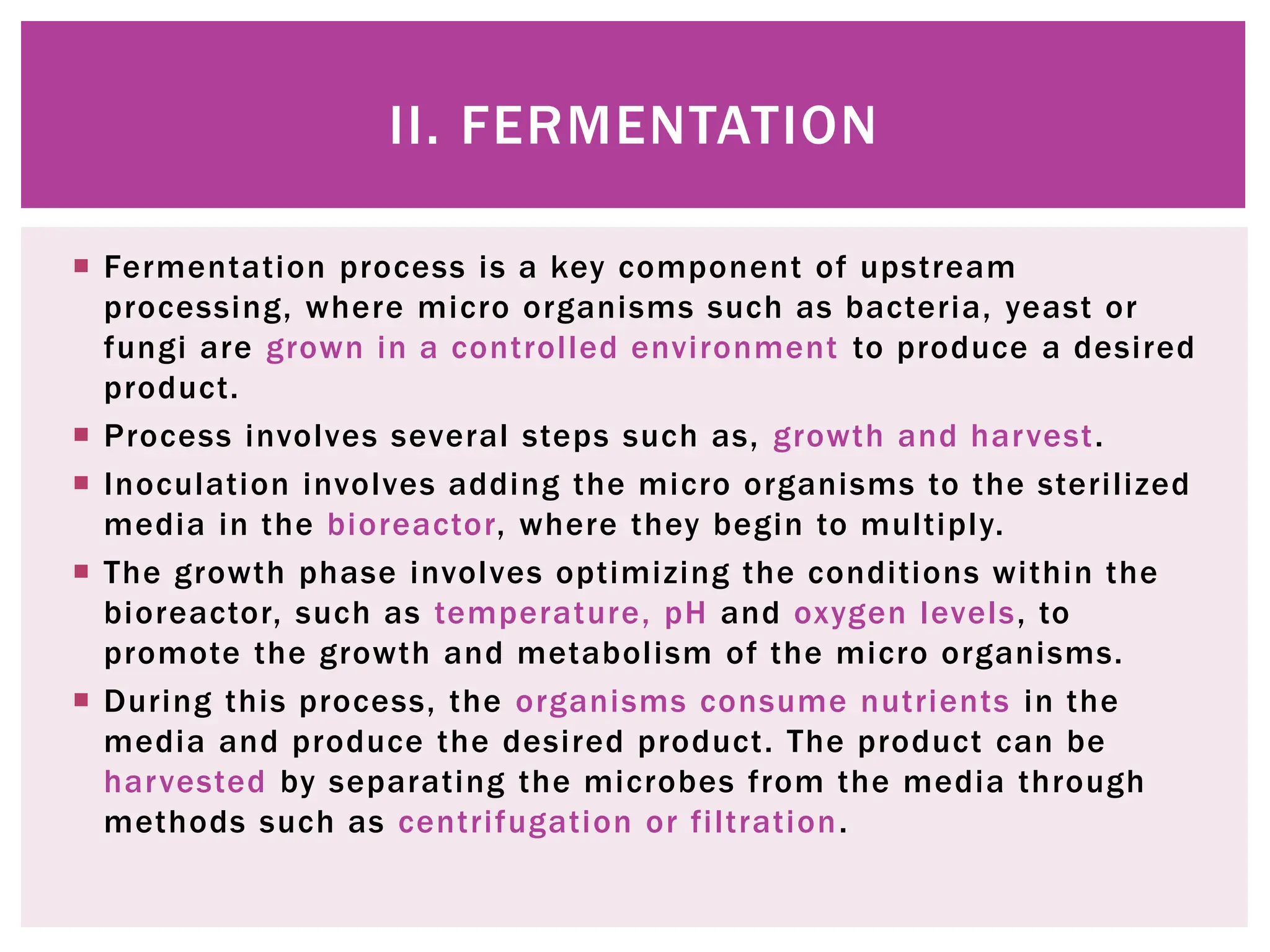

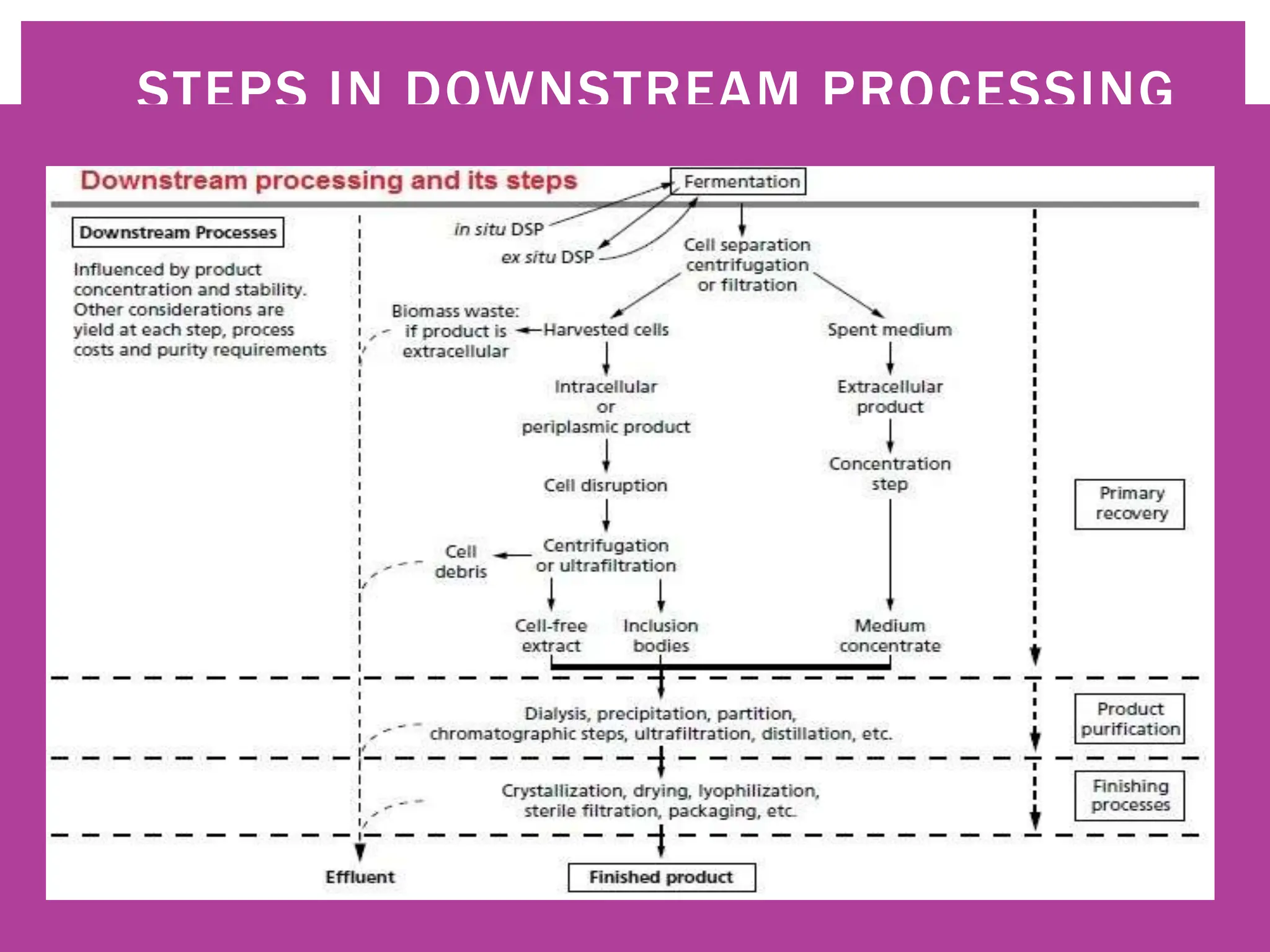

This document provides an overview of bio-processing. It discusses that bio-processing uses biological systems like microbes, cells and enzymes to produce products. It outlines that bio-processing involves upstream and downstream processing steps. Upstream processing includes culture isolation, inoculum preparation, media formulation and sterilization, and fermentation. Downstream processing purifies and isolates the product through separation, purification and formulation steps. Bio-processing is presented as an essential and environmentally friendly method for producing various products in industries.