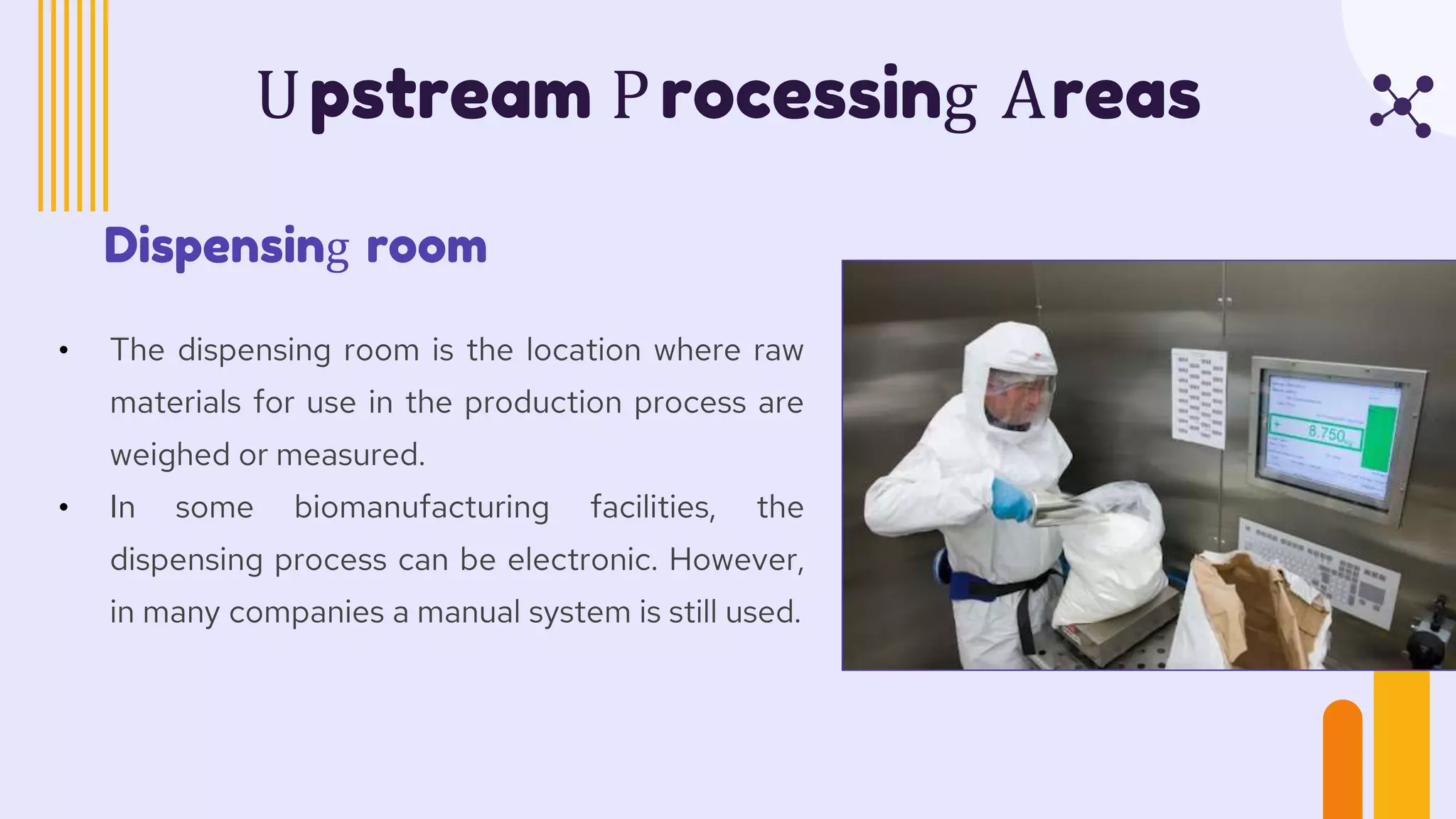

The document provides an overview of upstream and downstream processes. Upstream processes involve cell culture and media preparation, such as inoculum development, media development, and cell culture. Downstream processes involve steps after fermentation like cell disruption, purification, and final product isolation. Physical, chemical and enzymatic methods can be used for cell disruption in downstream processing. The document also discusses the definition, examples, and importance of upstream and downstream processes.