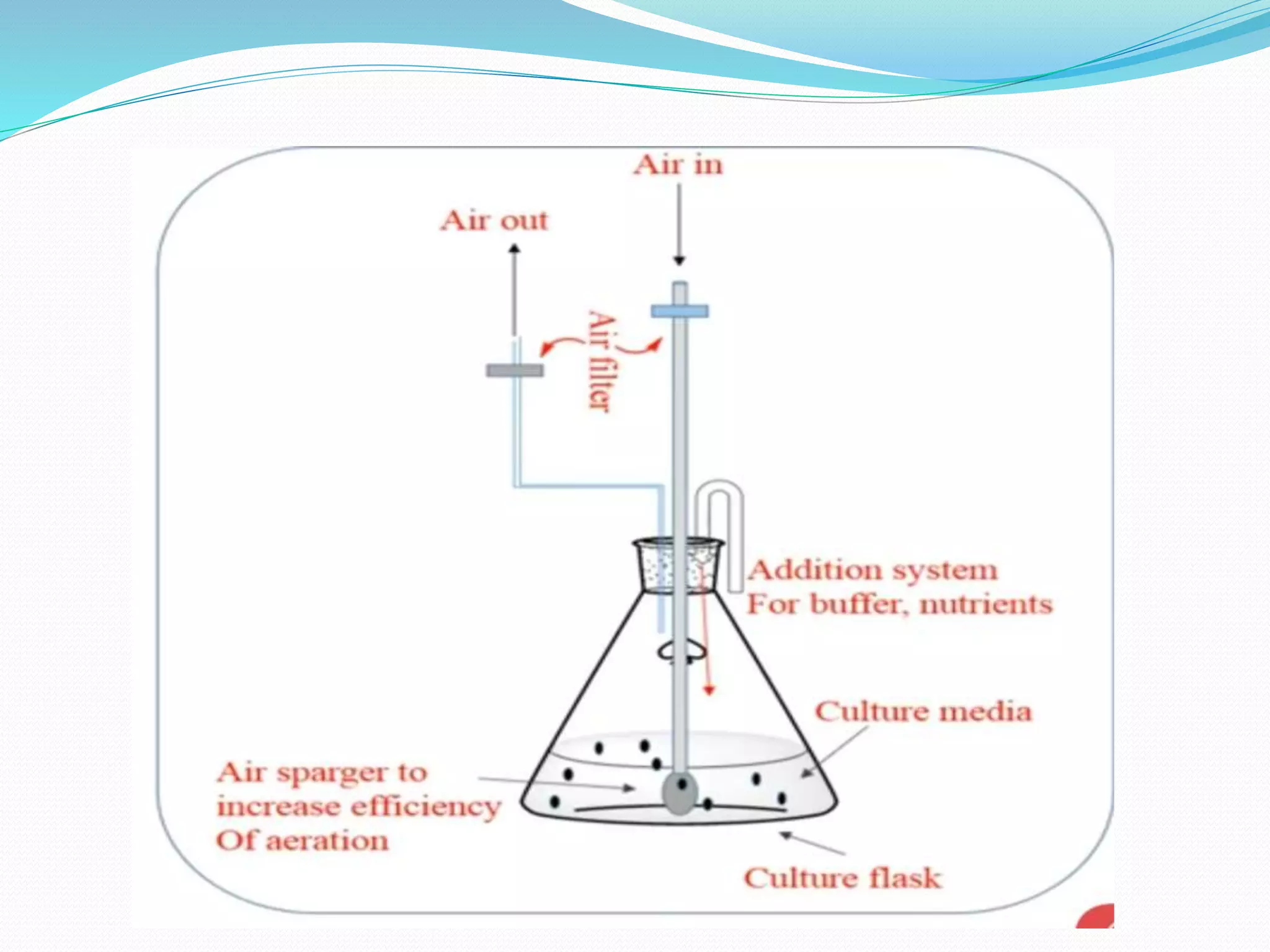

I. Batch culture is a technique used to grow microorganisms in a closed system containing a limited supply of nutrients. No nutrients or waste products are added or removed during growth.

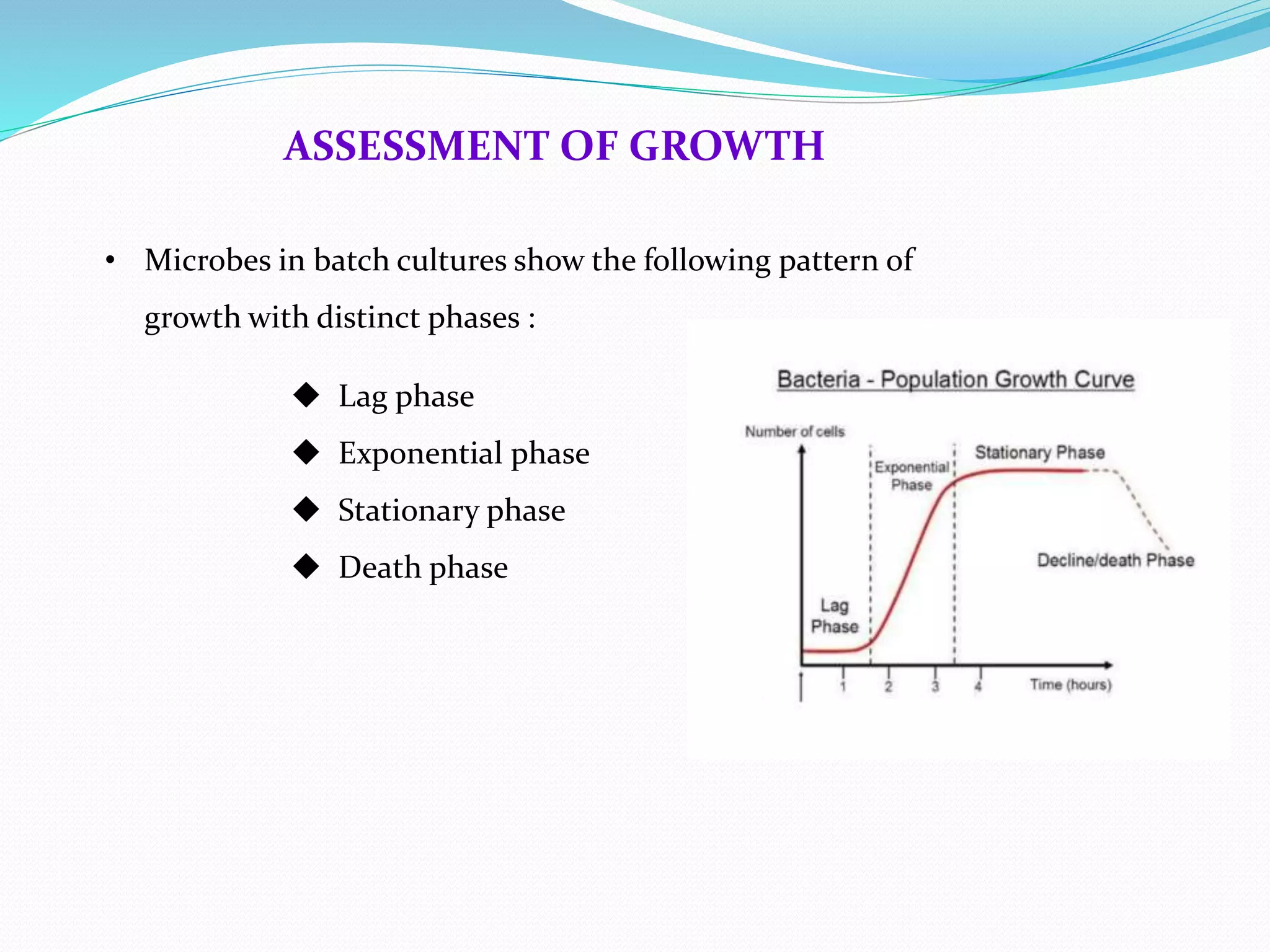

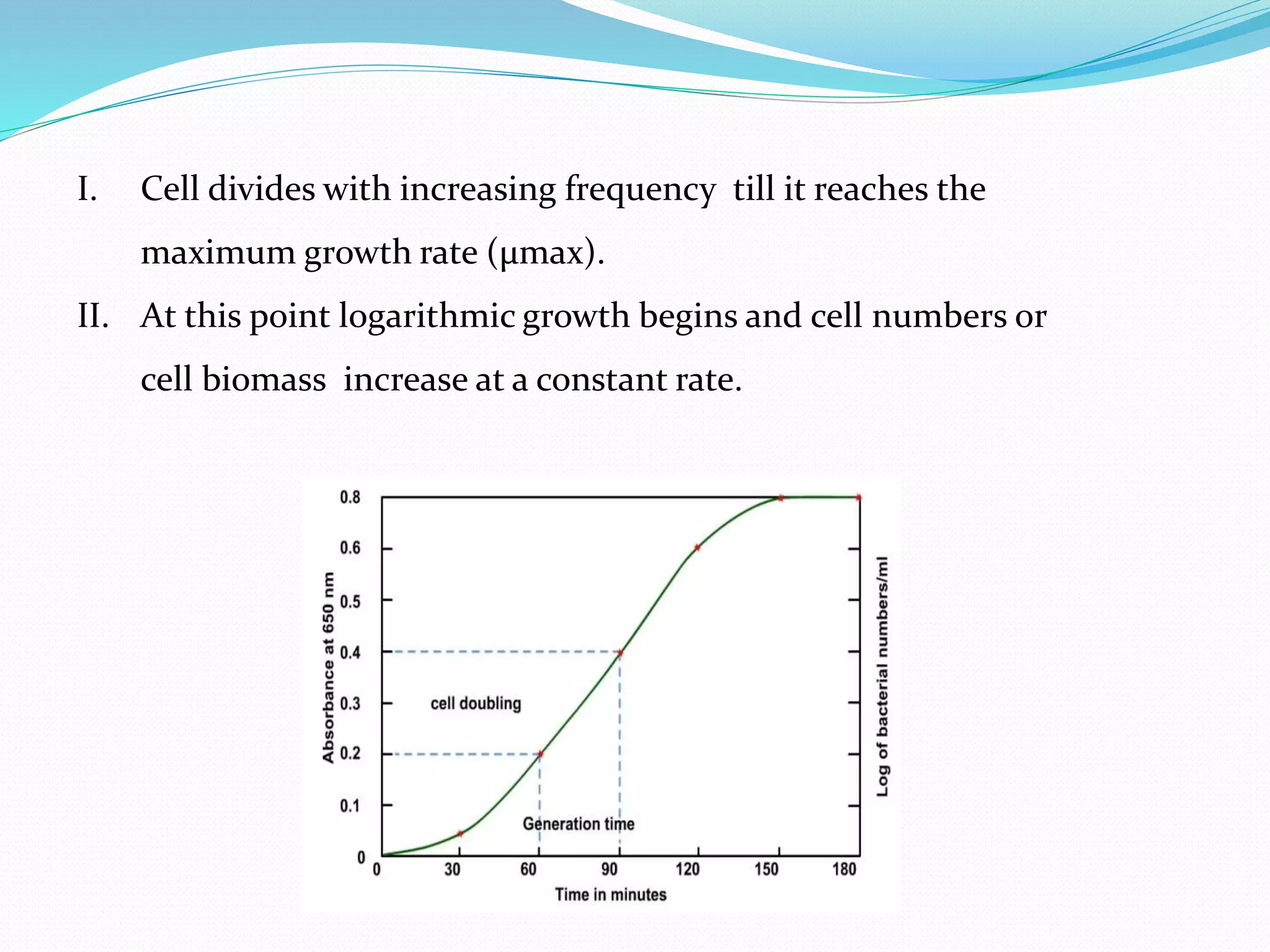

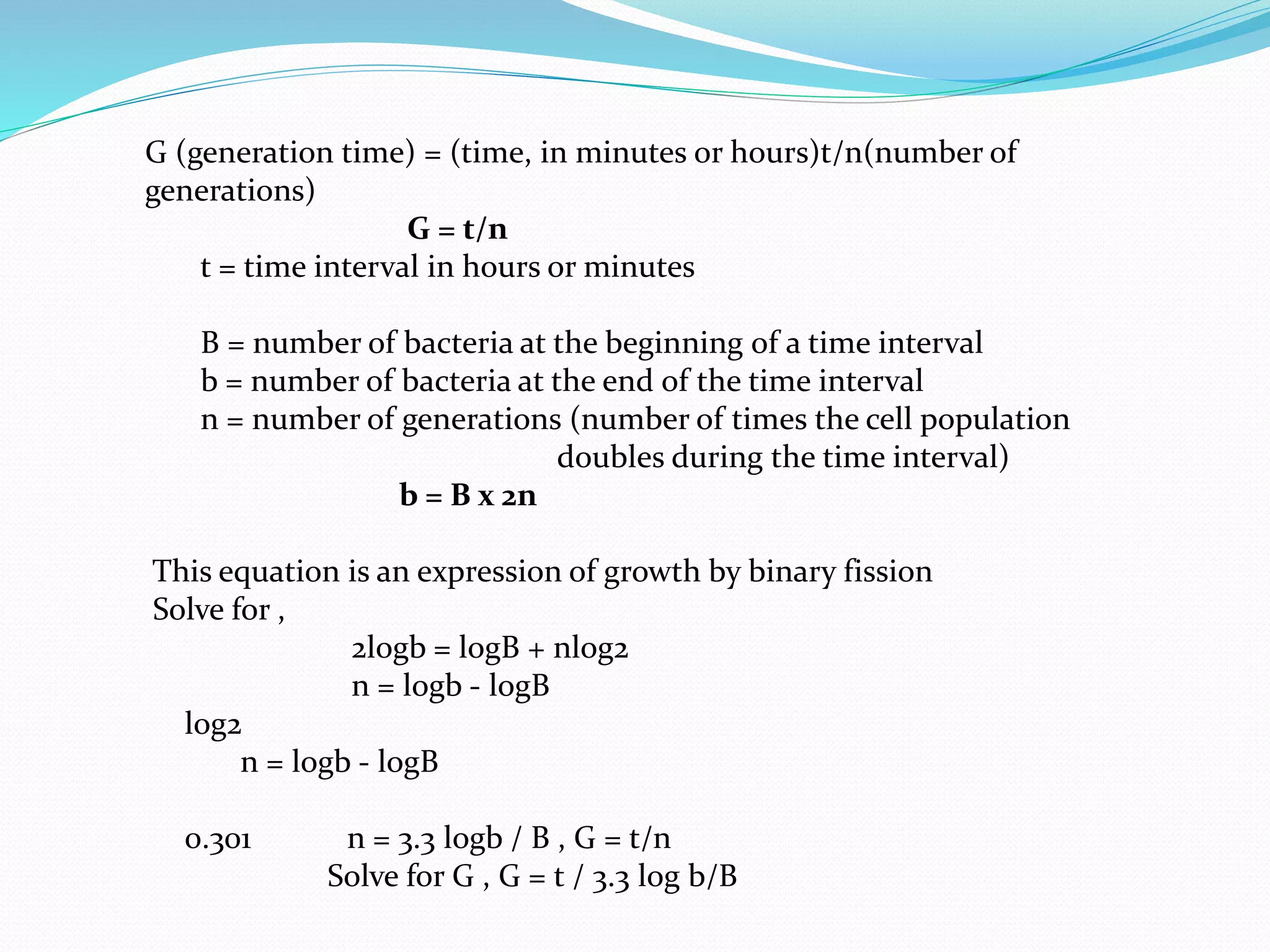

II. Microbial growth occurs in distinct phases - lag phase, exponential phase, stationary phase, and death phase. Population increases exponentially until nutrients are depleted, at which point the stationary phase begins.

III. Batch cultures are used industrially for the production of antibiotics, organic acids, and other metabolites through large-scale fermentation processes.