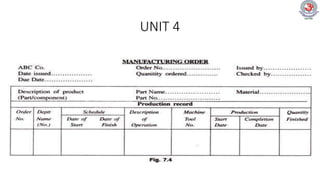

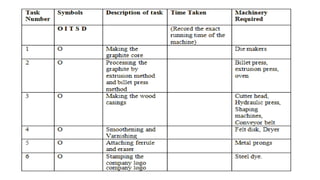

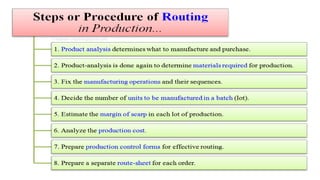

Routing involves determining the optimal path and sequence of operations to transform raw materials into finished products. Key aspects of routing include identifying the operations needed, their sequence, required departments and machines. Routing provides the basis for scheduling production and ensures efficient use of resources. Factors like the manufacturing process, available equipment and manpower can impact the routing procedure. Effective routing leads to benefits like reduced costs, improved quality and productivity.