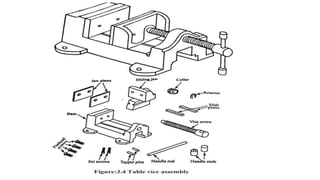

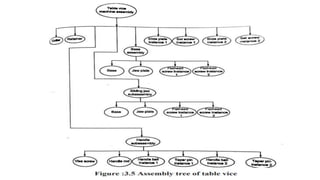

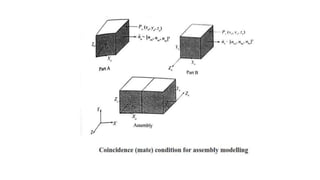

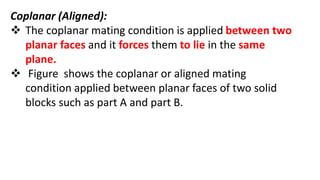

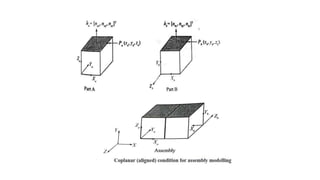

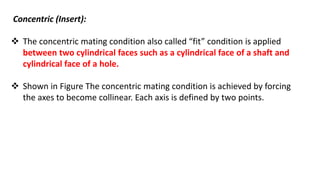

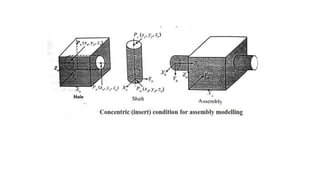

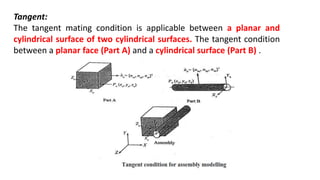

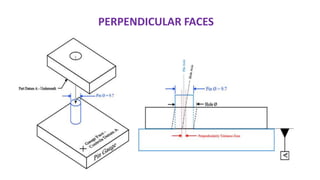

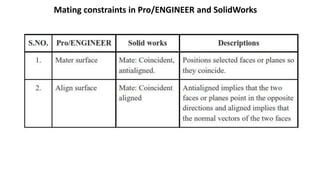

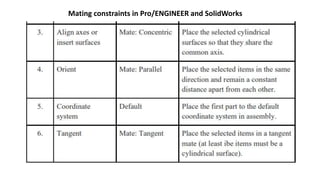

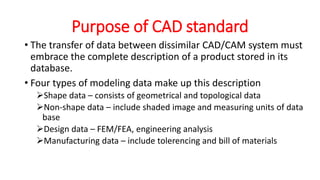

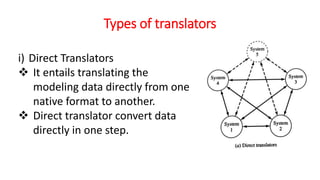

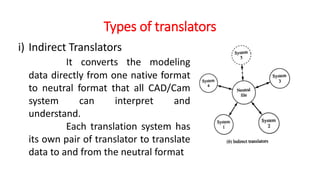

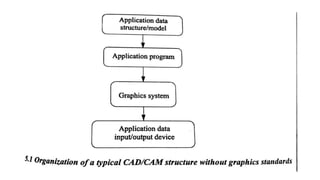

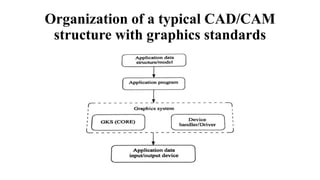

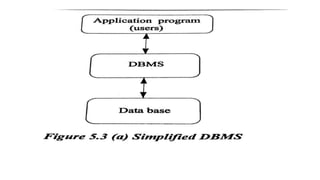

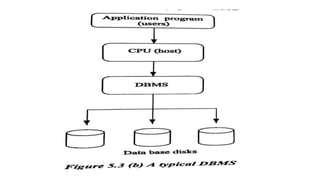

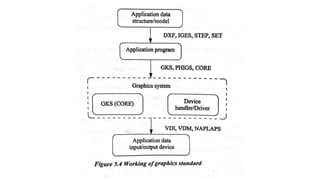

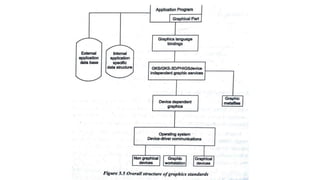

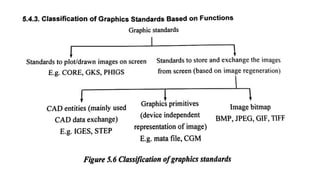

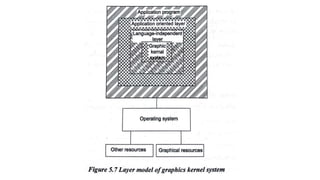

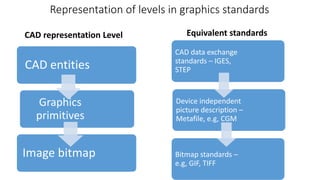

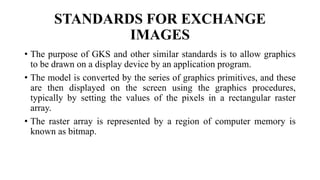

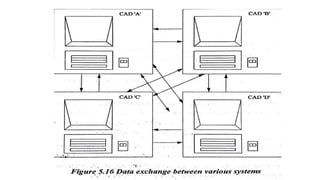

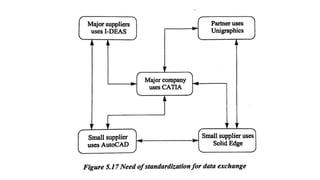

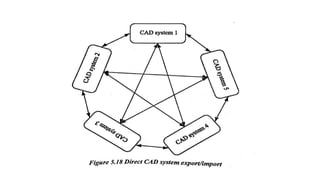

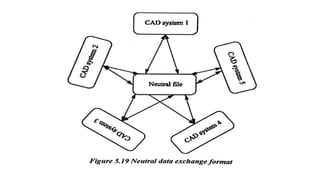

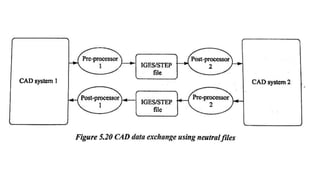

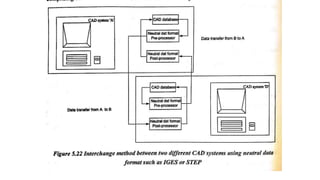

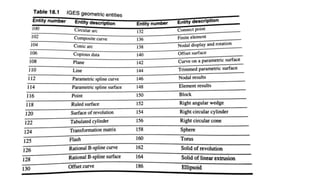

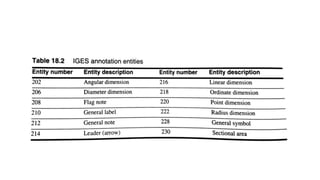

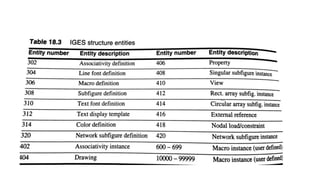

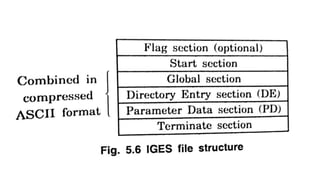

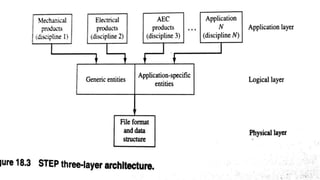

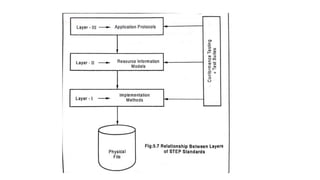

This document discusses CAD standards and assembly modeling. It covers three main approaches to assembly modeling: top-down, bottom-up, and combination. It also describes common mating conditions for assembly such as coincident, coplanar, concentric, and tangent. The purpose of CAD standards for data exchange between systems is explained. Common data exchange formats like IGES and STEP are introduced along with organizational structures to support graphics standards.