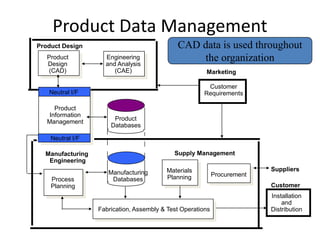

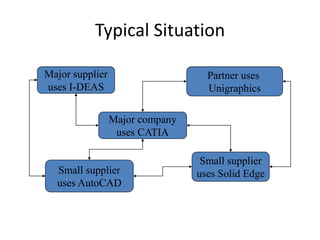

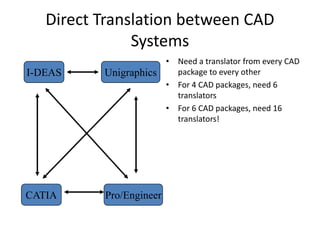

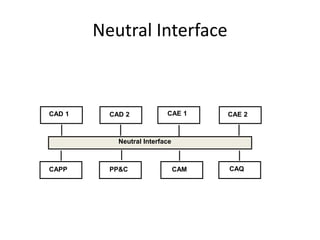

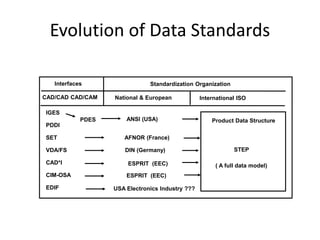

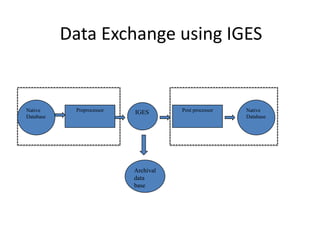

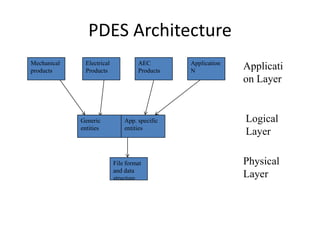

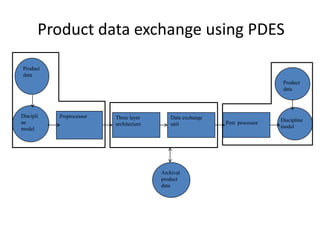

The document discusses standards for exchanging CAD data between different CAD systems. It notes that there are four main types of CAD data and that each CAD system uses its own proprietary format. Directly translating between each system's format would require many translators. Instead, neutral data exchange standards like IGES and PDES have been developed to allow CAD data to be imported and exported between different systems without information loss. The standards aim to support all types of manufacturing data and requirements in an open and adaptable manner.