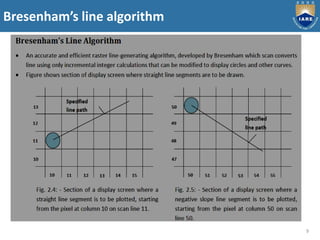

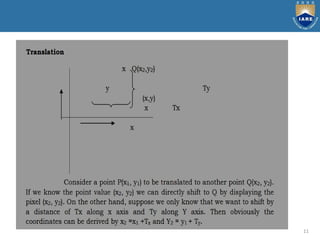

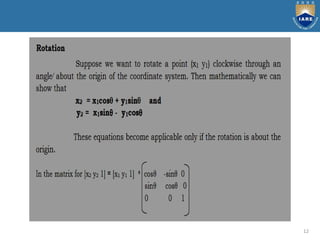

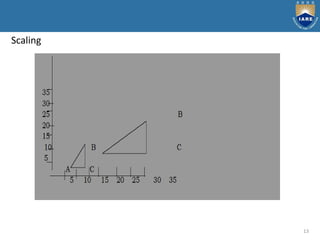

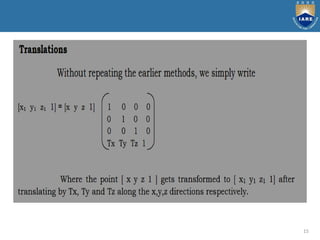

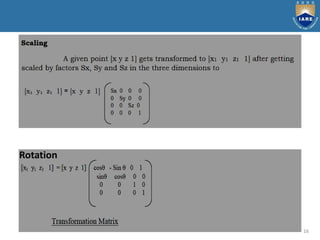

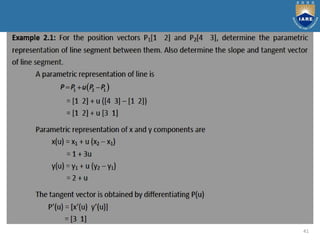

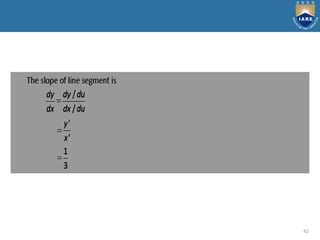

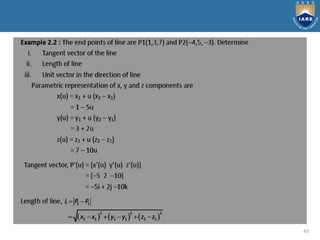

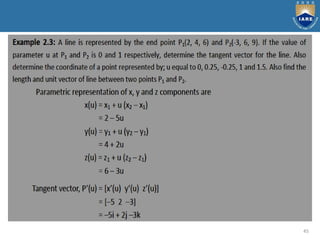

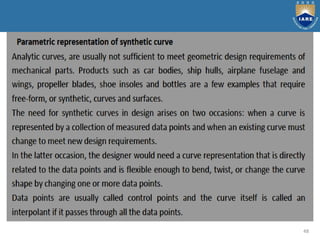

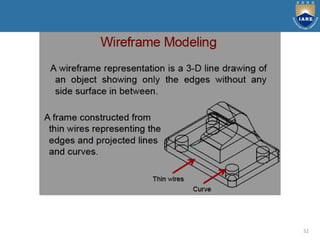

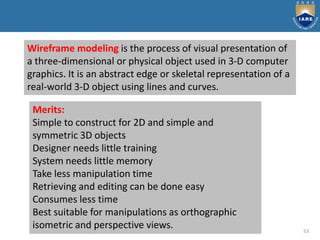

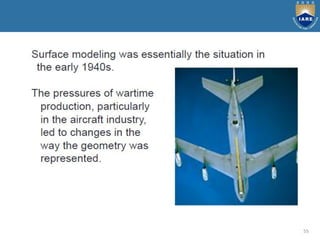

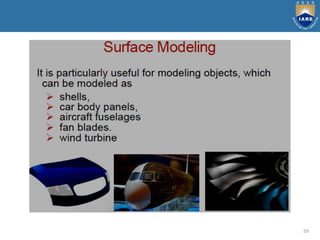

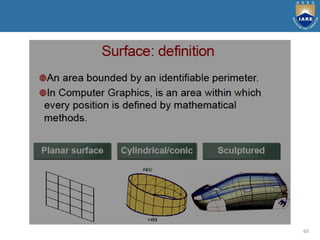

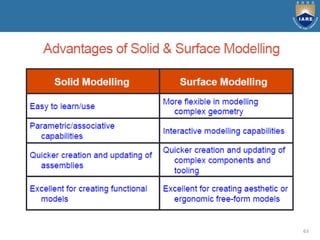

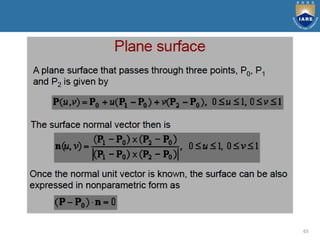

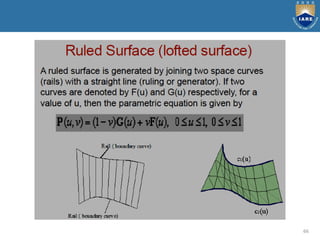

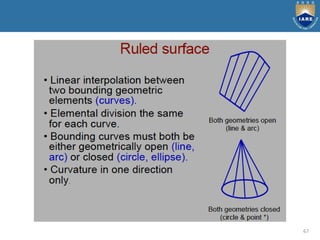

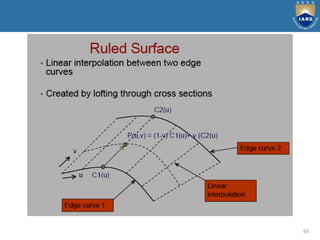

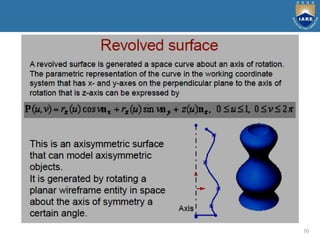

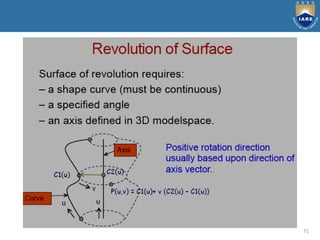

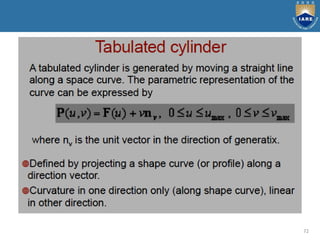

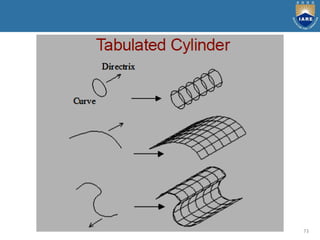

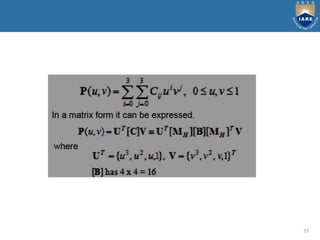

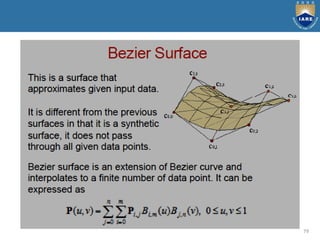

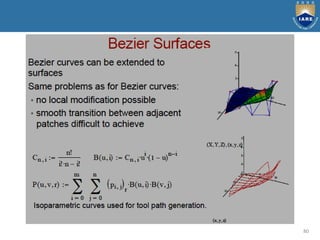

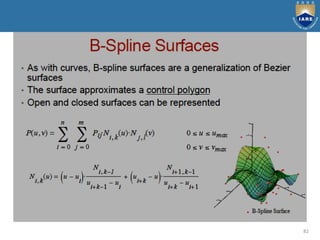

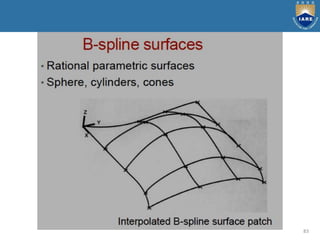

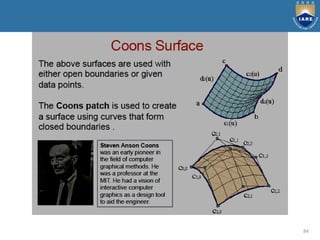

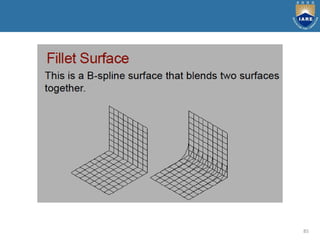

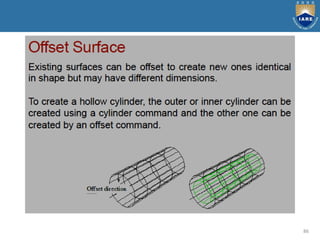

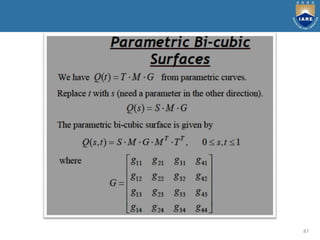

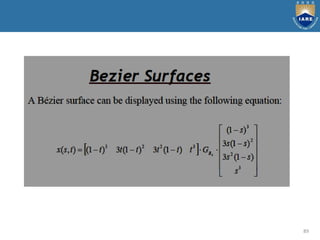

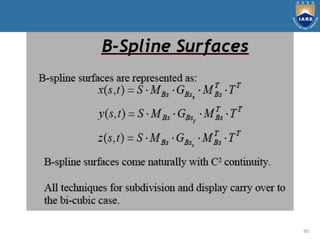

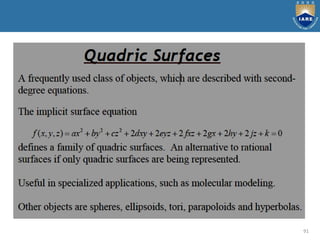

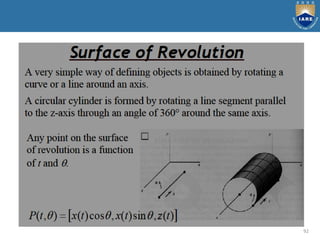

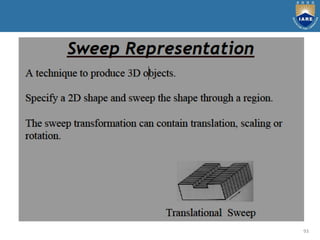

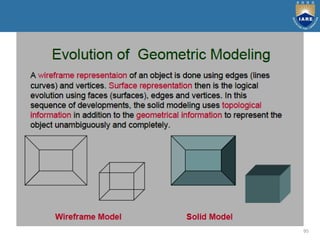

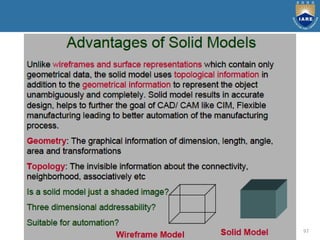

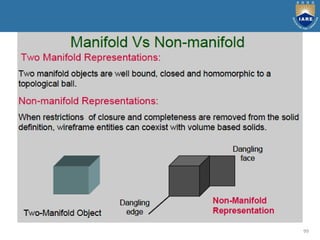

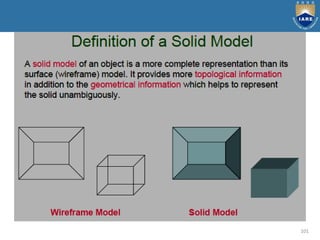

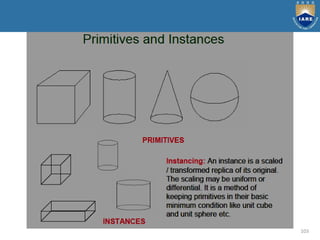

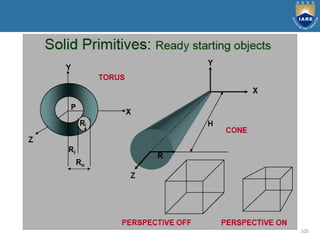

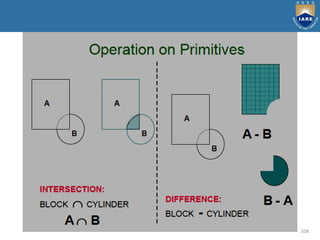

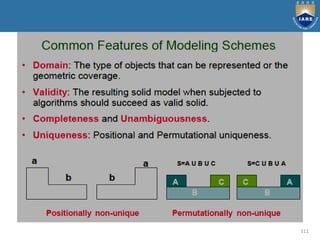

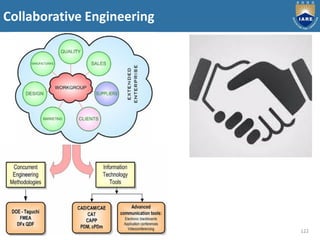

This document provides an overview of the topics covered in an advanced computer aided design course, including principles of computer graphics, CAD tools, surface modeling, parametric representation of surfaces, geometric modeling in 3D, data exchange formats and standards, and collaborative engineering. The syllabus covers points plotting, lines, Bresenham's circle algorithm, transformations, hidden surface removal, CAD system evaluation criteria, modeling techniques like wireframe, surface and solid modeling, parametric surfaces, solid modeling representations, data exchange formats like IGES and DXF, and collaborative design principles and tools.