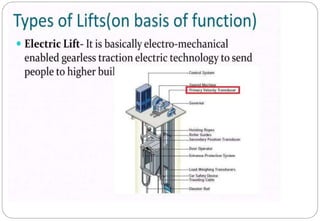

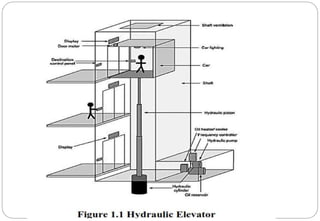

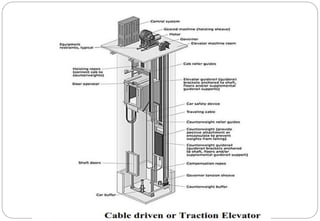

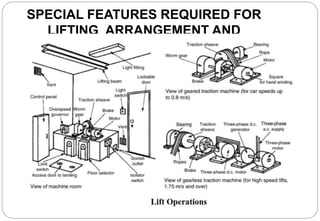

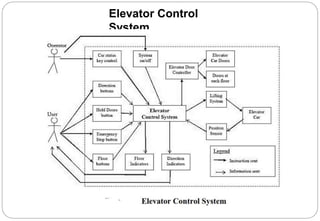

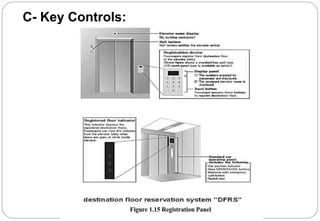

The document discusses different types of machinery used in tool rooms including hydraulic lifts, travelators, and elevator control systems. It describes how hydraulic lifts use pistons and hydraulic oil to lift cabins at speeds up to 200 feet per minute. Travelators are used commercially to increase customer flow and density. Elevator control systems aim to bring lifts to the correct floor safely and comfortably using inputs like sensors, buttons, and key controls and outputs that accelerate, decelerate, and travel at safe speeds. The document provides details on single automatic, selective collective, and group automatic elevator operation types.