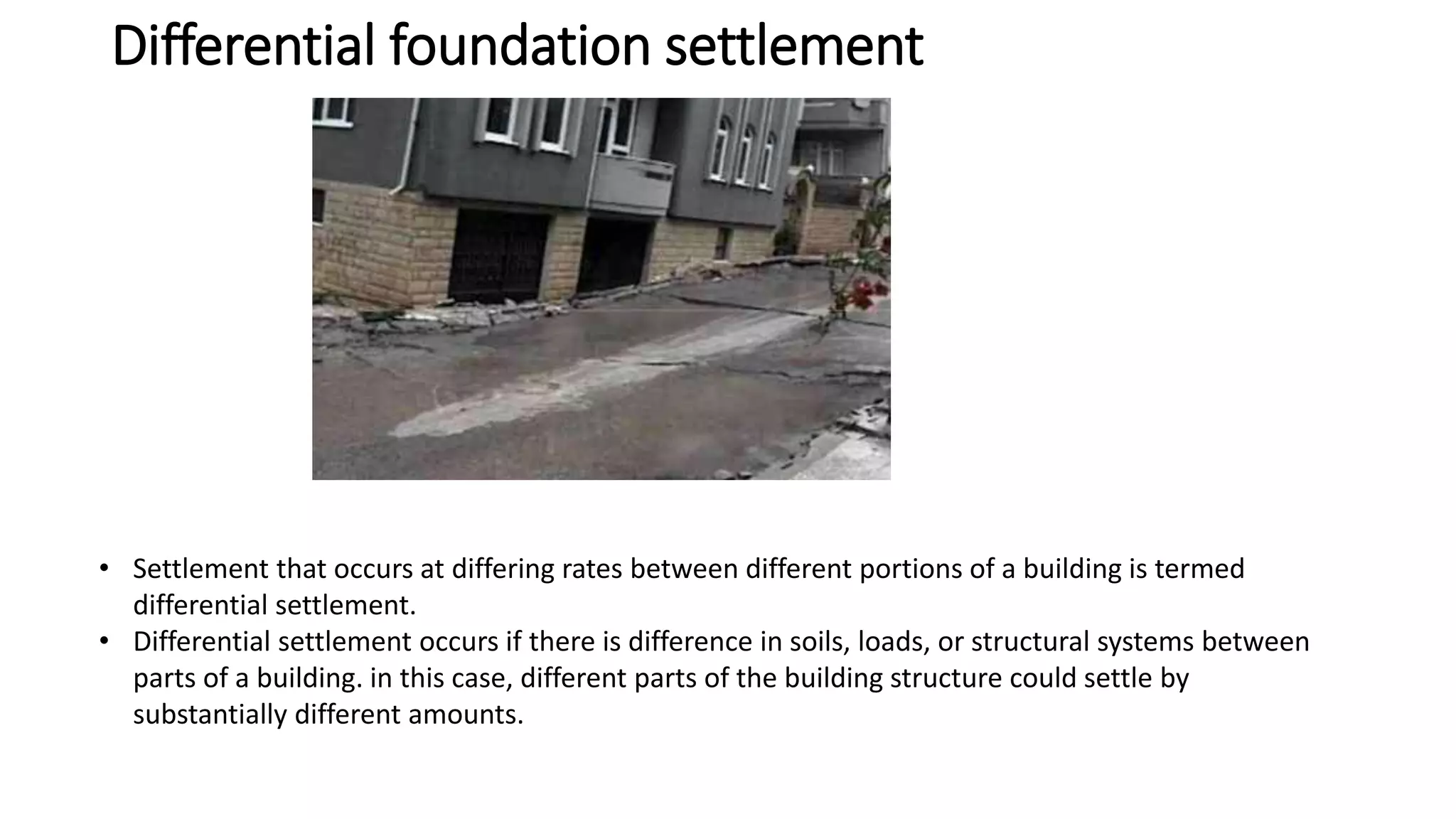

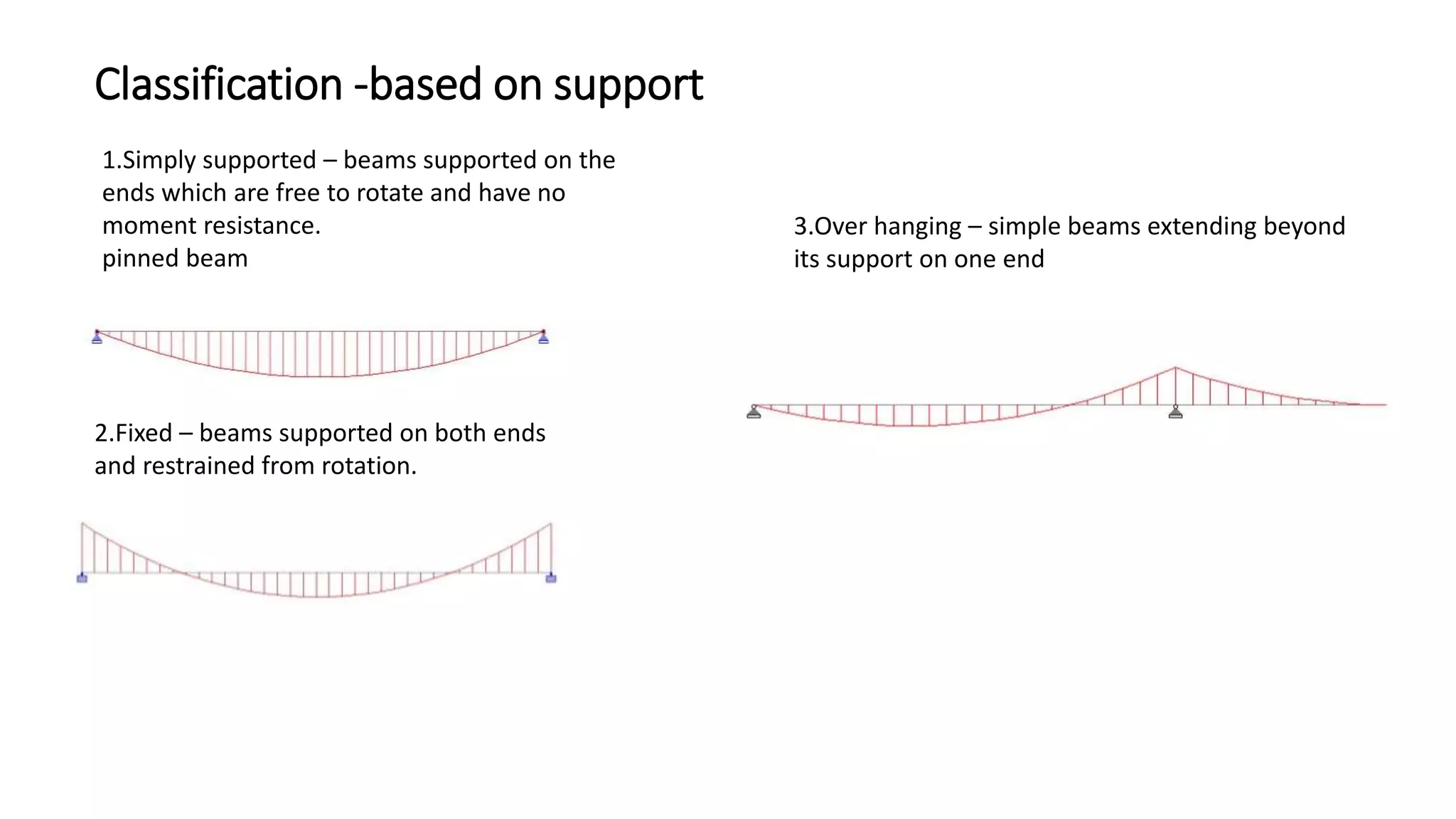

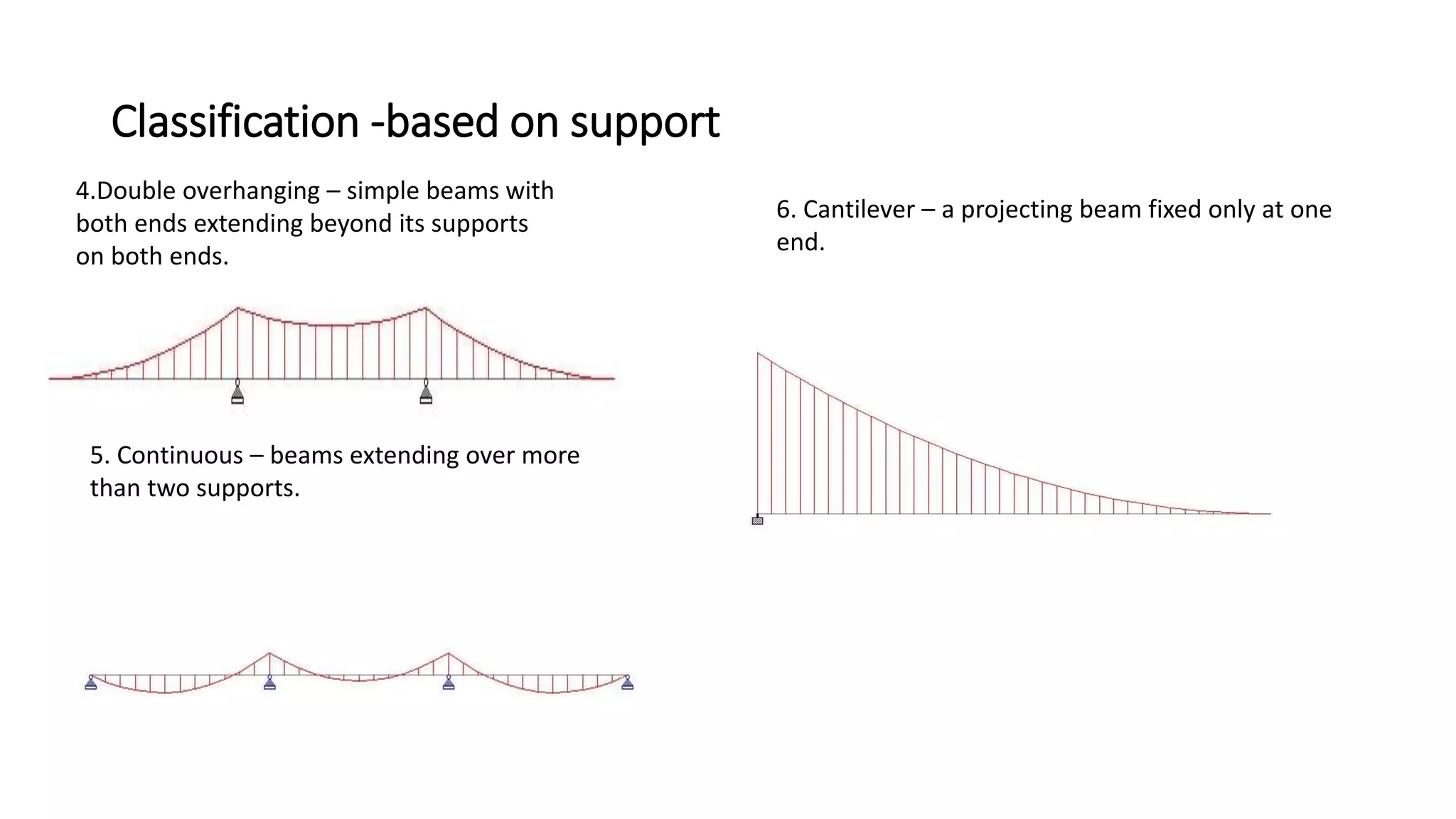

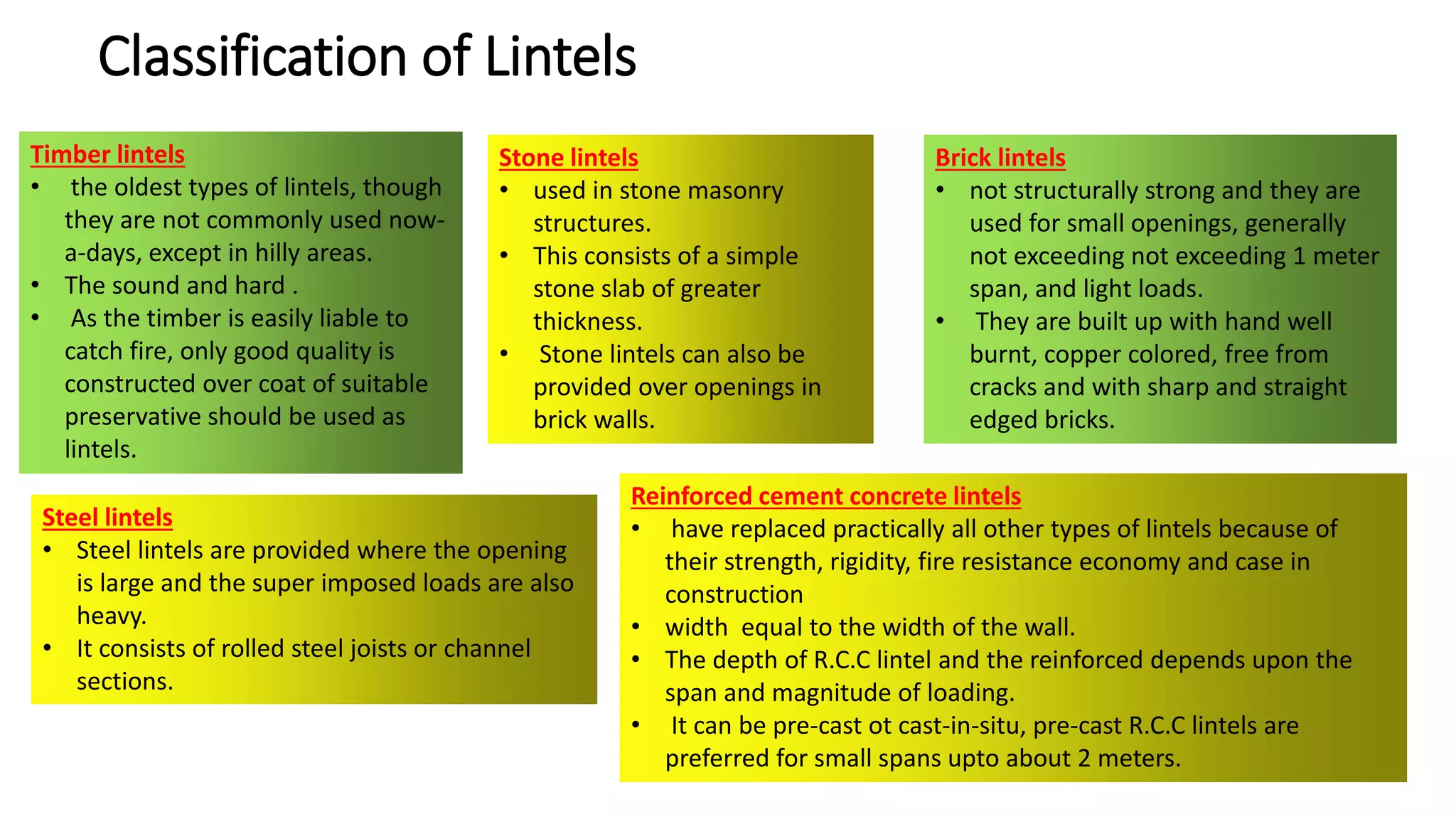

The document summarizes key building components and structures used in civil engineering. It discusses different types of foundations including shallow and deep foundations. It also describes different building materials like brick masonry, stone masonry, beams, columns, and their classifications. Requirements of good foundations and concepts of bearing capacity and settlement of foundations are explained.