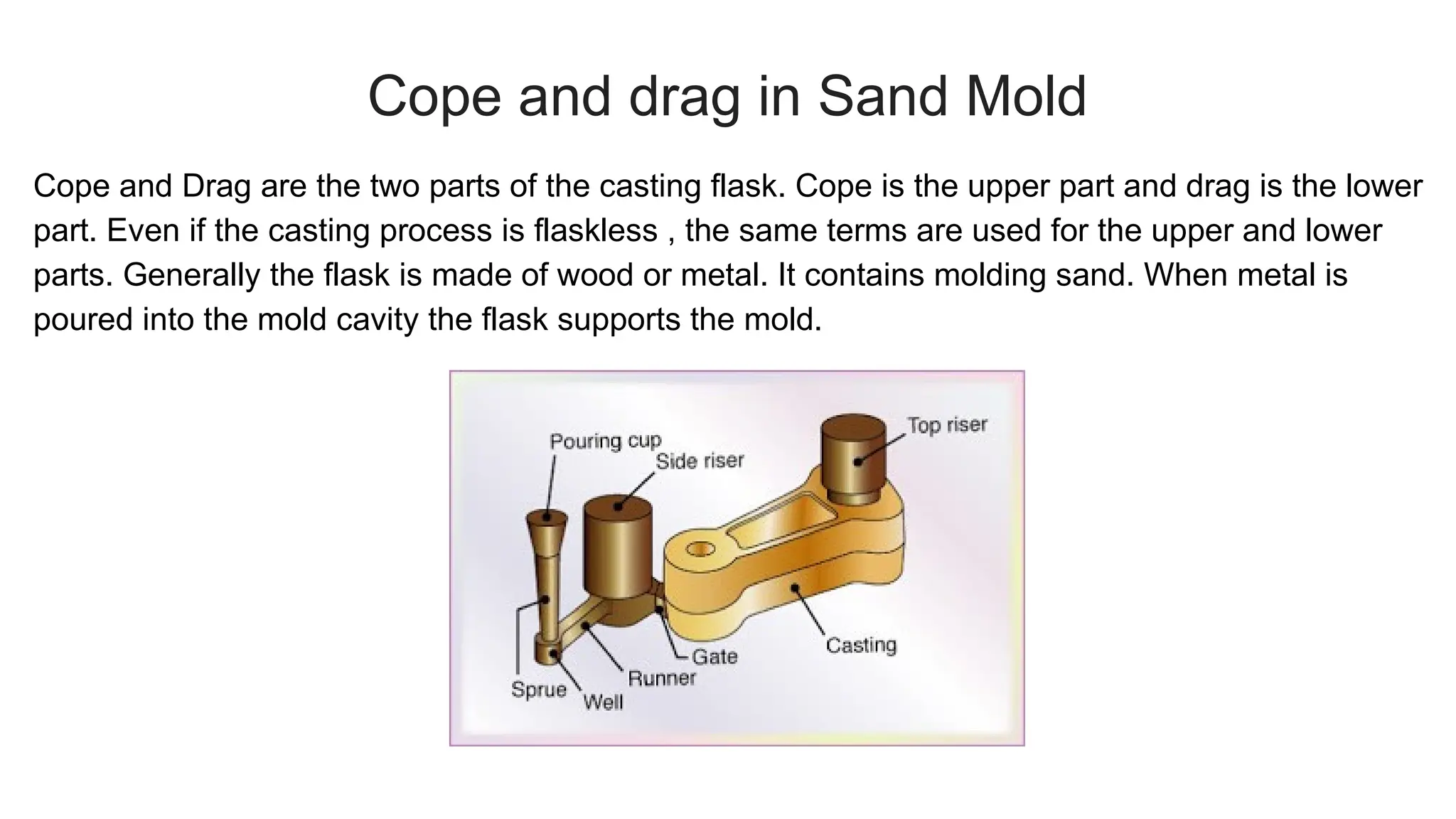

The document details the sand casting manufacturing process, which involves pouring liquid metal into a sand mold that solidifies. It discusses components of sand casting molds, types of sand and additives used, and defines essential parts like cope, drag, gating systems, and cores. Additionally, it presents problem-solving examples to optimize designs for casting while minimizing the need for sand cores.