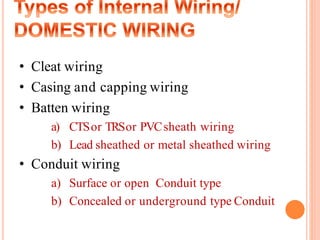

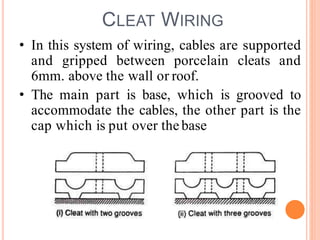

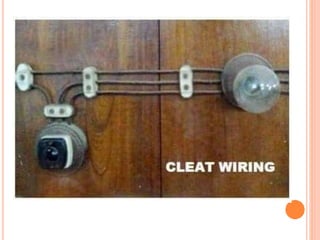

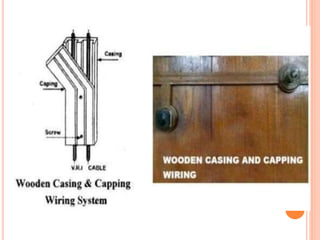

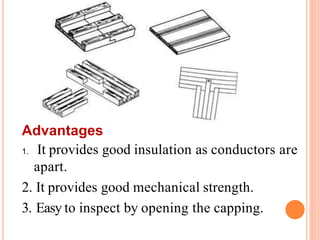

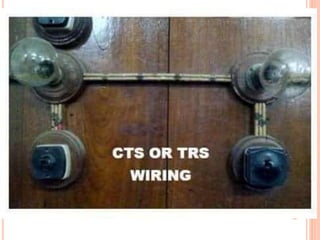

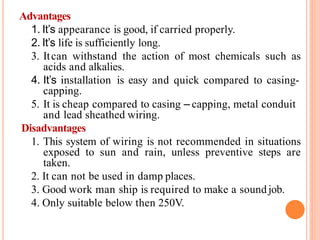

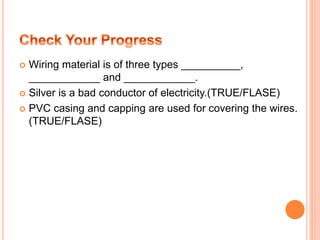

This document discusses different types of wiring systems used in household and industrial settings. It describes the materials used in wiring like copper, aluminum, and insulating materials. The key types of wiring discussed are cleat wiring, casing and capping wiring, batten wiring, and conduit wiring. Factors to consider when selecting a wiring system include durability, safety, appearance, cost, accessibility, and maintenance cost. The document also provides details on different wiring methods and the materials used in each.