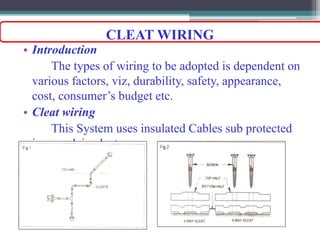

The document discusses different types of wiring systems including domestic, commercial, and industrial wiring. It describes wiring systems like tree system and looping system. It also discusses various types of wiring like cleat wiring, batten wiring, casing capping wiring, and conduit wiring. For each wiring type, it provides details on the materials used, installation process, advantages, and applications.

![SARDAR PATEL INSTITUTE OF TECHNOLOGY, PILUDARA

• Rakholiya bhavdip : [130680106039]

• Gevariya balkrushn : [130680106008]

• Patel parth : [130680106029]

(Branch: Civil Engineering)

Guided by : Vaishali .D Patel](https://image.slidesharecdn.com/wiringcon-220815054615-cf6fc6dd/75/Wiring_Con-ppt-1-2048.jpg)