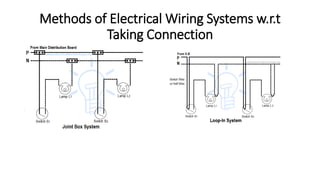

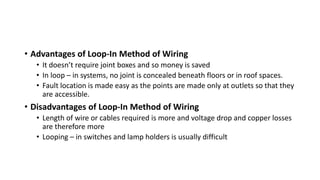

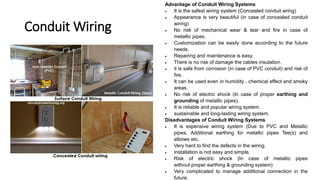

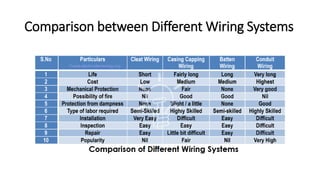

The document discusses various types of electrical wiring systems, including their advantages and disadvantages. It describes loop-in wiring, cleat wiring, casing and capping wiring, batten wiring, lead sheathed wiring, and conduit wiring. For each type, it provides 1-2 sentences on the general description and then lists their advantages and disadvantages in point form. The document aims to inform readers on the different internal wiring methods used in electrical installations.