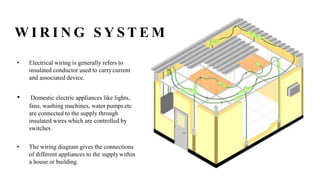

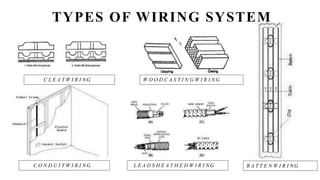

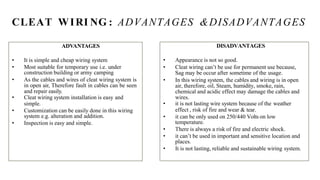

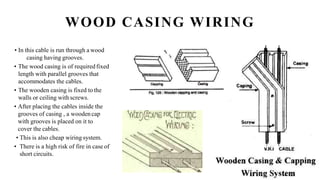

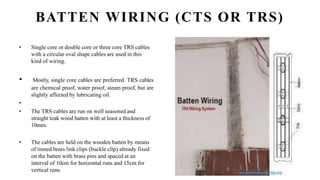

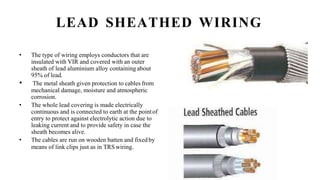

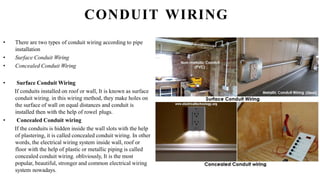

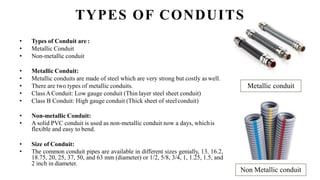

The document discusses different types of wiring systems used in electrical installations. It describes cleat wiring, wood casing wiring, batten wiring, lead sheathed wiring, and conduit wiring. Conduit wiring uses insulated conductors run through metallic or non-metallic pipes or conduits. It is considered the most common and reliable system due to its durability and safety. Each wiring system has advantages like ease of installation, and disadvantages like fire risk or unsuitability in certain environments. Metallic conduit wiring is typically the strongest but most expensive option.