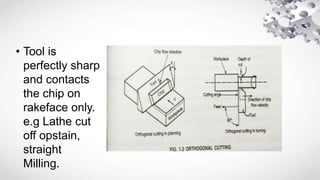

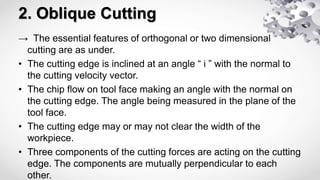

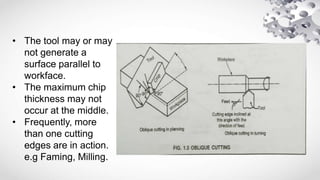

This document discusses two types of metal cutting methods: orthogonal cutting and oblique cutting. Orthogonal cutting involves a perpendicular cutting edge where only two cutting force components act in a plane. Oblique cutting features an inclined cutting edge where three mutually perpendicular cutting force components act and the cutting edge may not clear the entire workpiece width. Examples of orthogonal cutting include lathe cut-off operations while oblique cutting includes farming and milling where multiple cutting edges are often involved.