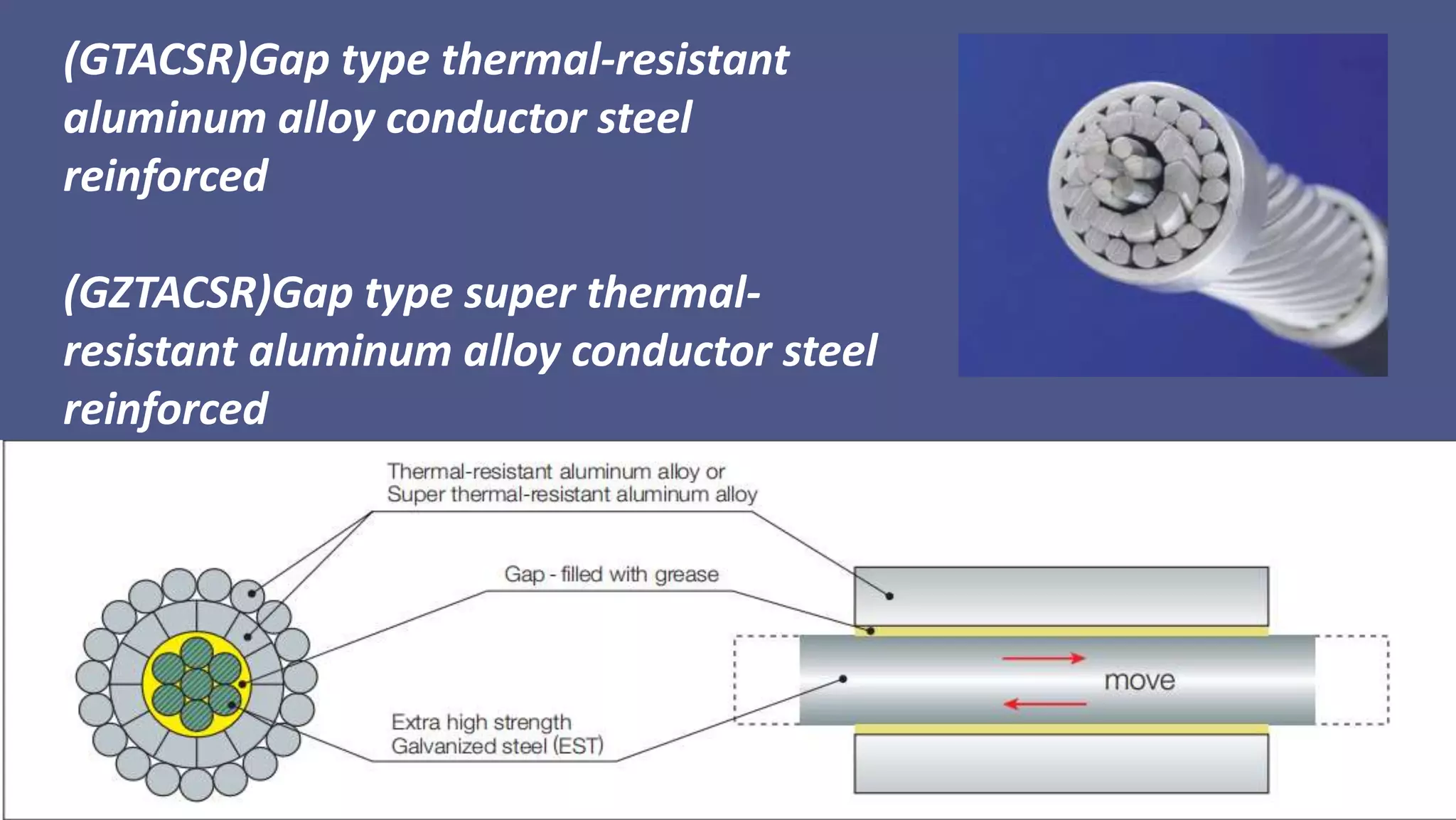

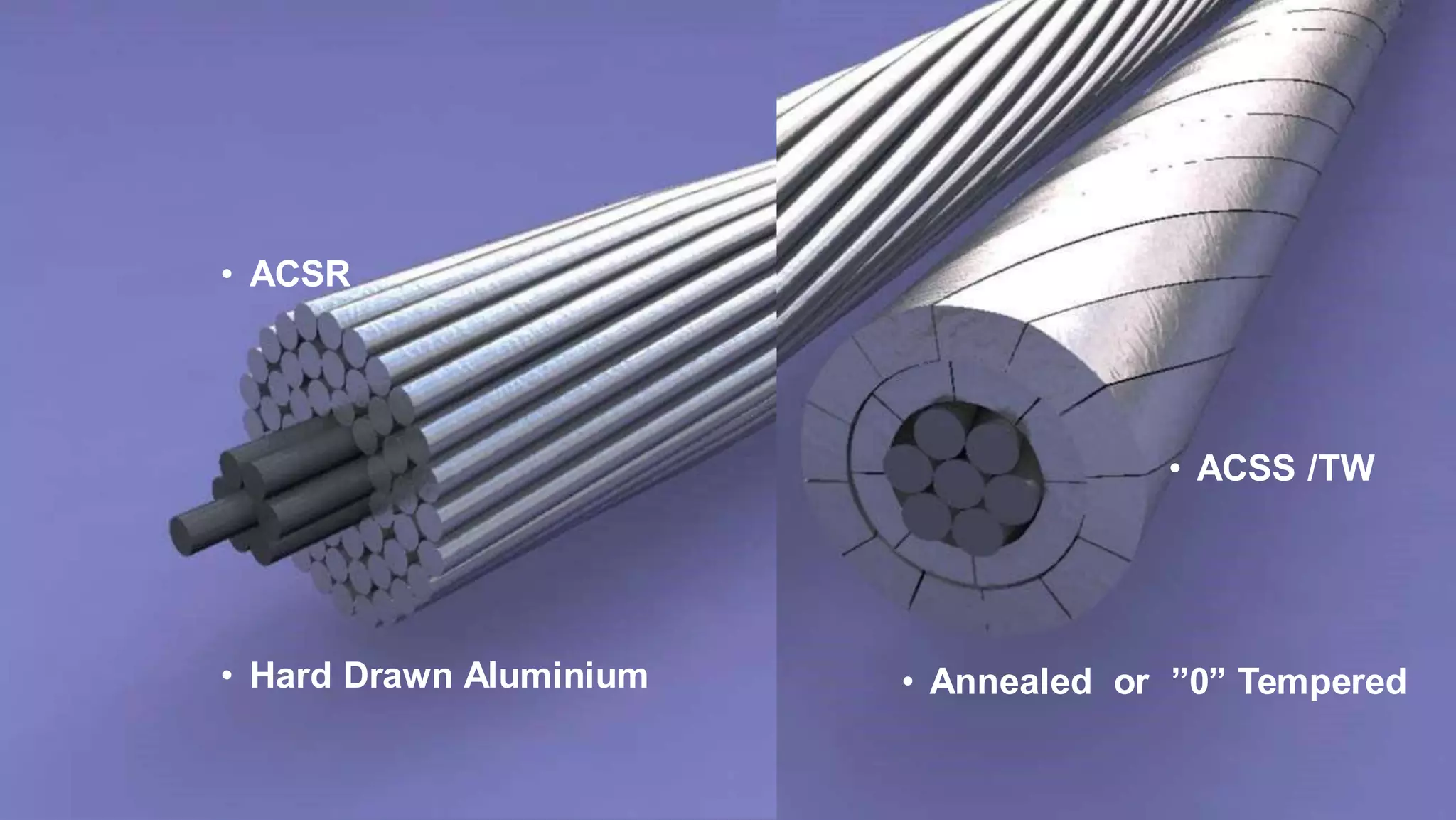

This document discusses different types of conductors used in overhead transmission lines. It describes solid conductors which are used in substations for short lengths. Hollow conductors provide better cooling and are also used in substations. Stranded conductors are the most common as they are flexible, easy to transport and install. Specific stranded conductors discussed include AAC, AAAC, ACSR, ACSS, ACCR, and ACCC which differ in their material composition and properties like strength, corrosion resistance and current carrying capacity. New high temperature alloys like TAI and ZTAI can carry higher currents than conventional conductors. Gap type conductors like GTACSR and GZTACSR provide even greater capacity without requiring tower

![(Super) Thermal resistant aluminum alloy [TAI, ZTAI]

Thermal-resistant aluminum alloy (TAI) and Super thermal

resistant aluminum alloy (ZTAI) improve its

thermal-resistant characteristics by adding

zirconium. ZTAI and TAI can keep its tensile

strength in high temperature condition.

TAI can withstand up to 150ºC and

can carry 1.6 times current of Hard drawn

aluminum .

ZTAI can withstand up to 210ºC and can carry 2.0 times

current of Hard drawn aluminum .

Both TAI and ZTAI maintain nearly the same mechanical and

electrical characteristics as Hard drawn aluminum](https://image.slidesharecdn.com/typesofconductors-210625051334/75/Types-of-conductors-in-high-termission-lines-20-2048.jpg)