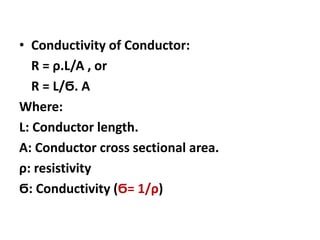

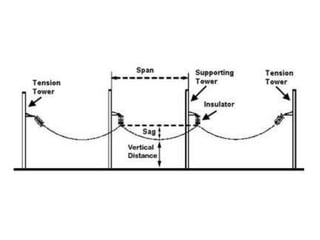

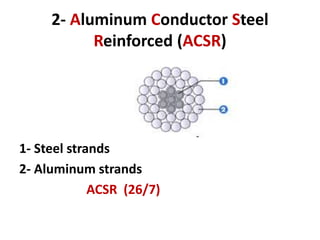

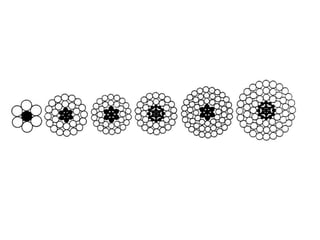

This document discusses the design considerations for overhead transmission lines. It outlines key electrical factors like minimizing voltage drop and power loss. Mechanically, the lines must withstand conductor weight and weather conditions. The main components are conductors, supports, insulators, and cross arms. Common conductor materials include copper for its conductivity, aluminum for its light weight and lower cost, and steel-cored aluminum which increases aluminum's strength. Aluminum, steel-cored aluminum, and galvanized steel are widely used depending on the transmission distance and power level. Cadmium copper also provides increased strength over pure copper.