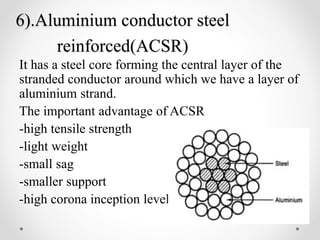

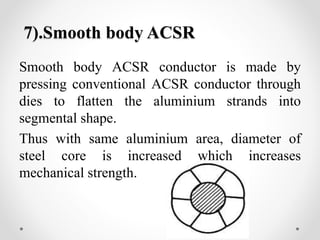

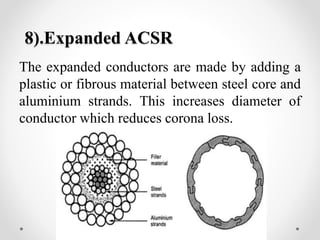

The document discusses different types of conductors used in transmission lines. It describes 8 types: hard drawn copper, cadmium copper, steel core copper, copper welded, all aluminium, aluminium conductor steel reinforced (ACSR), smooth body ACSR, and expanded ACSR. Each type has its own advantages - for example, ACSR conductors have high tensile strength, are lightweight, and have small sag. The document concludes that each conductor has its own application depending on factors like conductivity, strength, cost and local conditions.