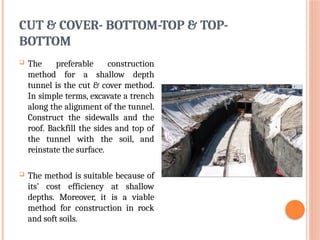

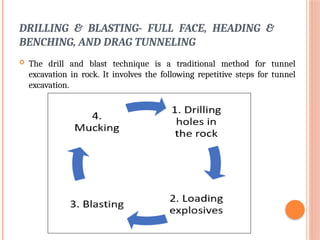

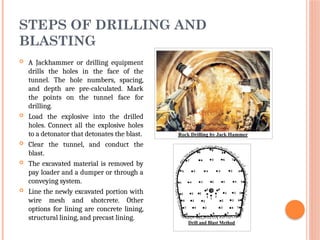

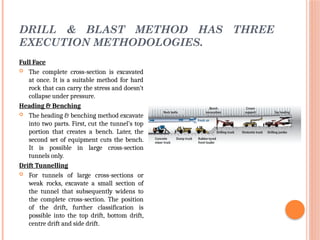

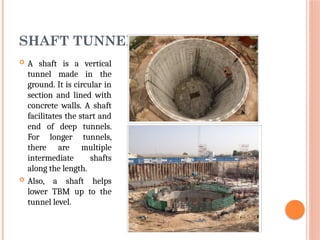

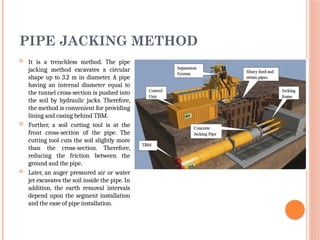

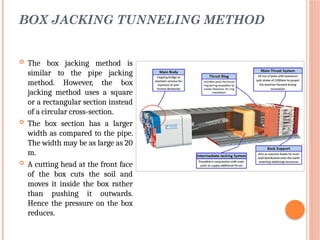

The document outlines various tunnel construction techniques, emphasizing their significance, requirements, and methods such as boring, cut & cover, and drilling & blasting. It highlights the advantages of tunnels over bridges in certain terrains and conditions, including efficiency and safety during wartime. Additionally, it discusses the selection criteria for tunneling methods based on geological conditions, project requirements, and construction speed.