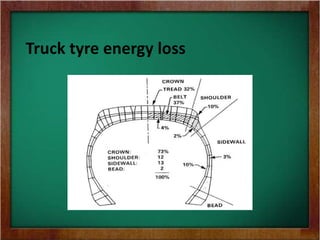

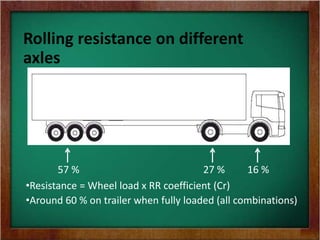

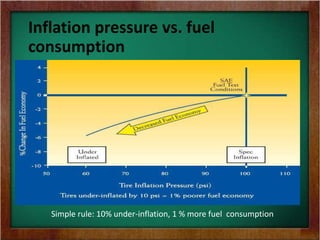

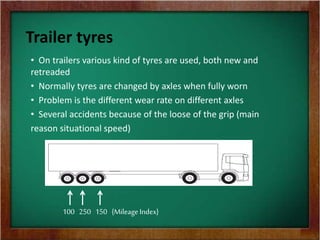

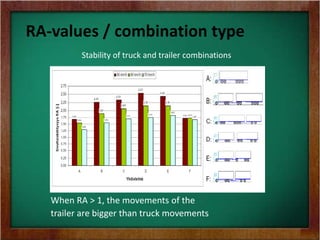

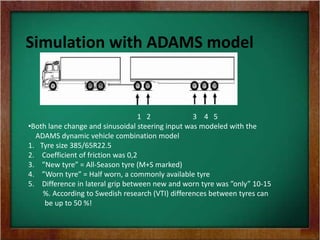

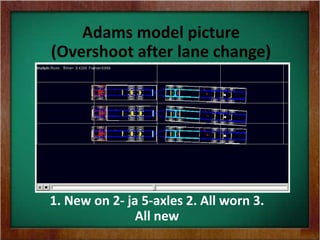

This document discusses truck tire rolling resistance, fuel economy, and safety. It finds that 57% of tire energy loss occurs on the trailer when fully loaded. Under-inflated tires can increase fuel consumption by 1% per 10% under-inflation. For winter driving, tires need adequate tread and a rubber compound suitable for winter conditions. The document recommends new tires with good grip on the 2nd and 5th trailer axles to improve stability, with other axles using lower rolling resistance tires. Retreaded tires can be used on some trailer axles depending on use. Simulations found new tires on the 2nd and 5th axles most reduced trailer movements during lane changes.