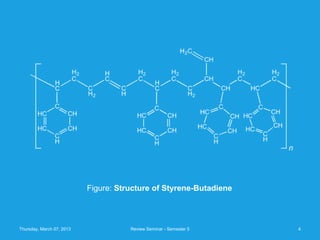

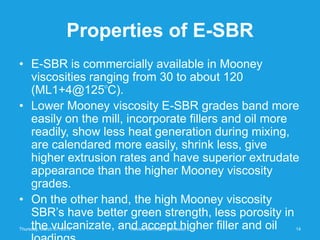

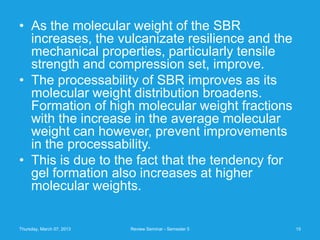

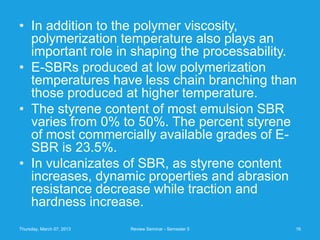

Styrene-butadiene rubber (SBR) is a synthetic rubber derived from styrene and butadiene monomers. There are two main types - emulsion polymerized SBR (E-SBR) and solution polymerized SBR (S-SBR). E-SBR accounts for over 50% of car tire production and is also used in conveyor belts, footwear, adhesives and more. S-SBR offers improved properties for tires and is increasingly used. The document discusses the production, properties and applications of SBR.