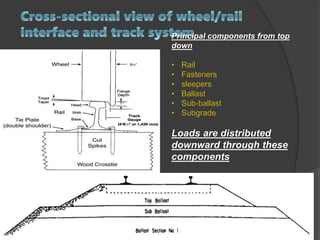

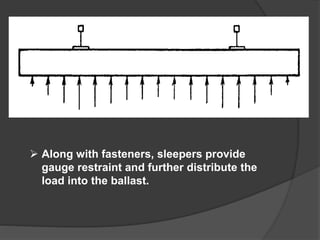

The document discusses axle load in railways, which is the total weight felt by the railway for all wheels connected to a given axle. It is important for track design as both tracks and vehicles are rated for a maximum axle load to prevent damage. The dynamic loads from moving trains exceed static loads. Track strength depends on factors like rail weight, sleeper density, stability, and ballast. Loads transfer downward through the components of the track structure. Formulas like Nadal and Wagner relate vertical and lateral wheel and rail forces, which must be properly balanced to prevent wheel climb derailments during turns.