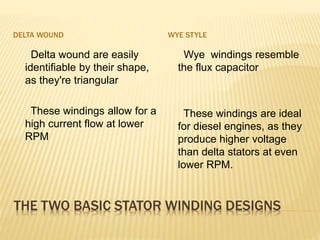

The document is a seminar presentation about alternators, highlighting their function in automotive charging systems alongside batteries and voltage regulators. It explains the mechanics, components, and diagnostics of alternators while contrasting them with older generator systems. Additionally, it covers the importance of correct voltage regulation and common issues like bearing failure that can affect alternator performance.