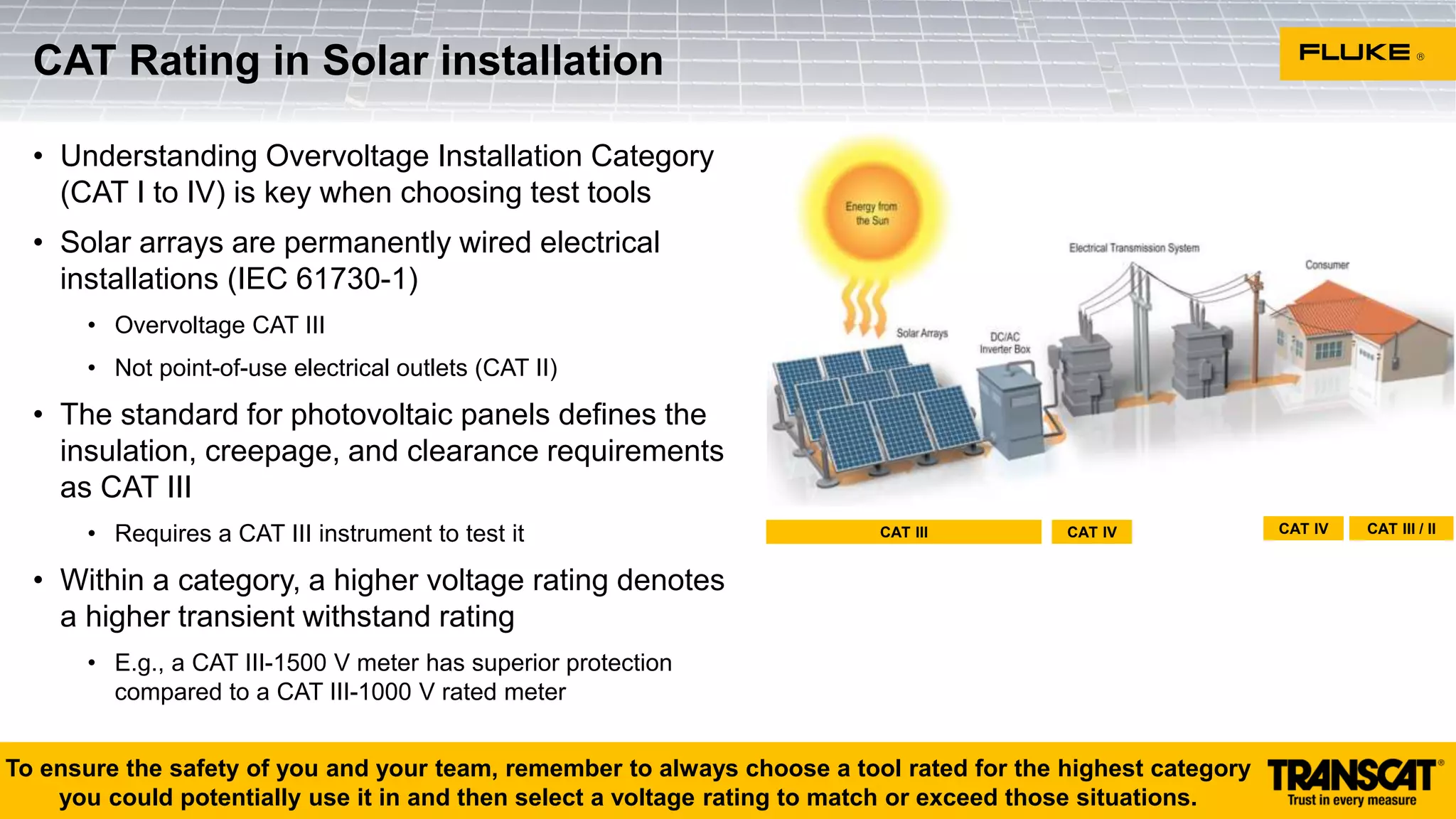

The document provides a comprehensive overview of tools and techniques for commissioning and maintaining photovoltaic (PV) systems, emphasizing safety and performance testing per IEC 62446-1 standards. It details the understanding of overvoltage categories, the importance of using appropriately rated test equipment, and outlines the specific testing workflow during installation and maintenance. It also stresses the significance of proper grounding, voltage, and insulation resistance testing to ensure reliability and longevity in PV installations.

![When installing, commissioning, and executing maintenance on PV systems,

technicians verify safety and performance per IEC 62446-1 standards

Safety

IEC 62446-1 requires that the AC circuits are tested first, then the following six

DC circuit tests need to be performed, preferably in this order:

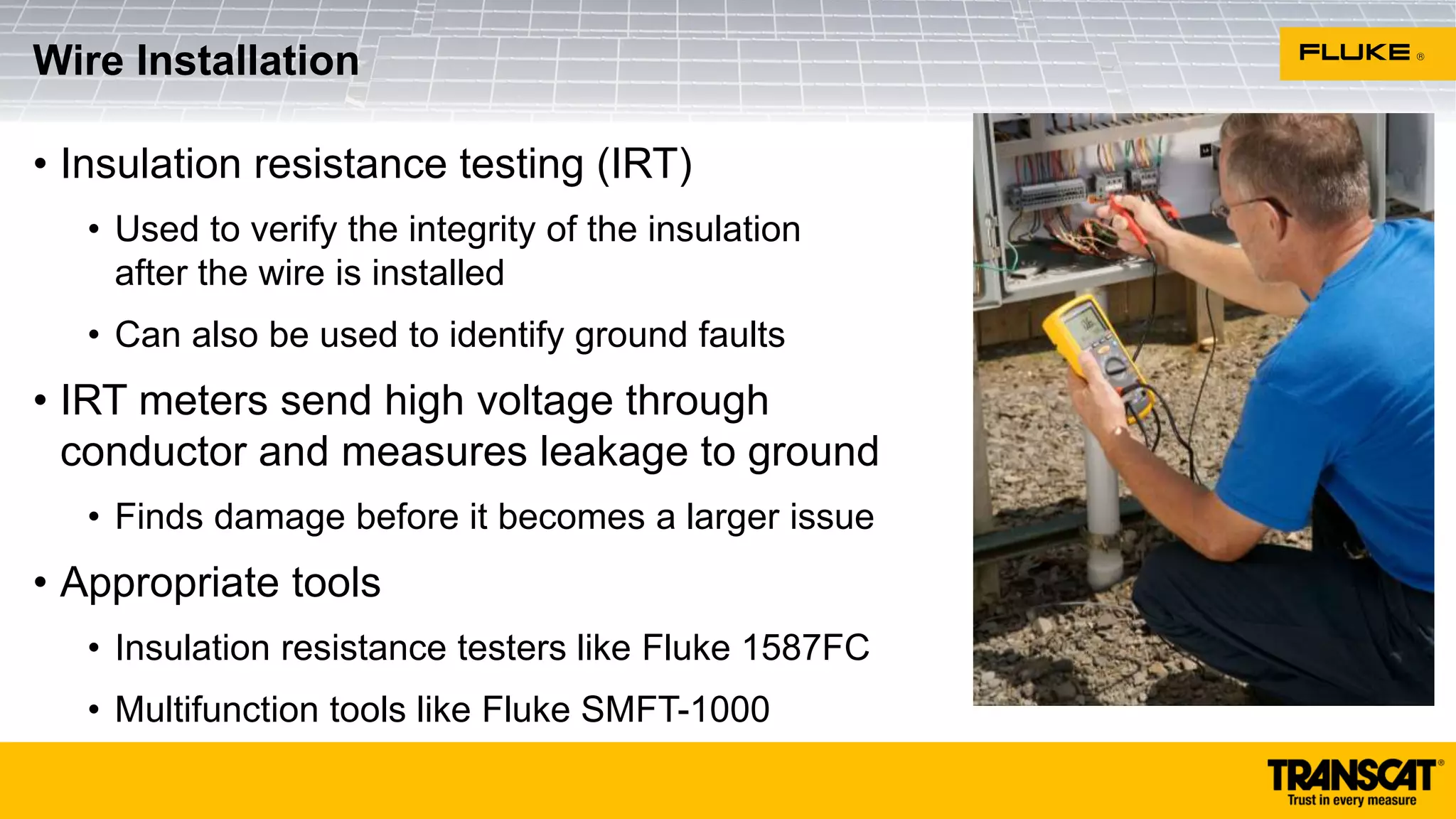

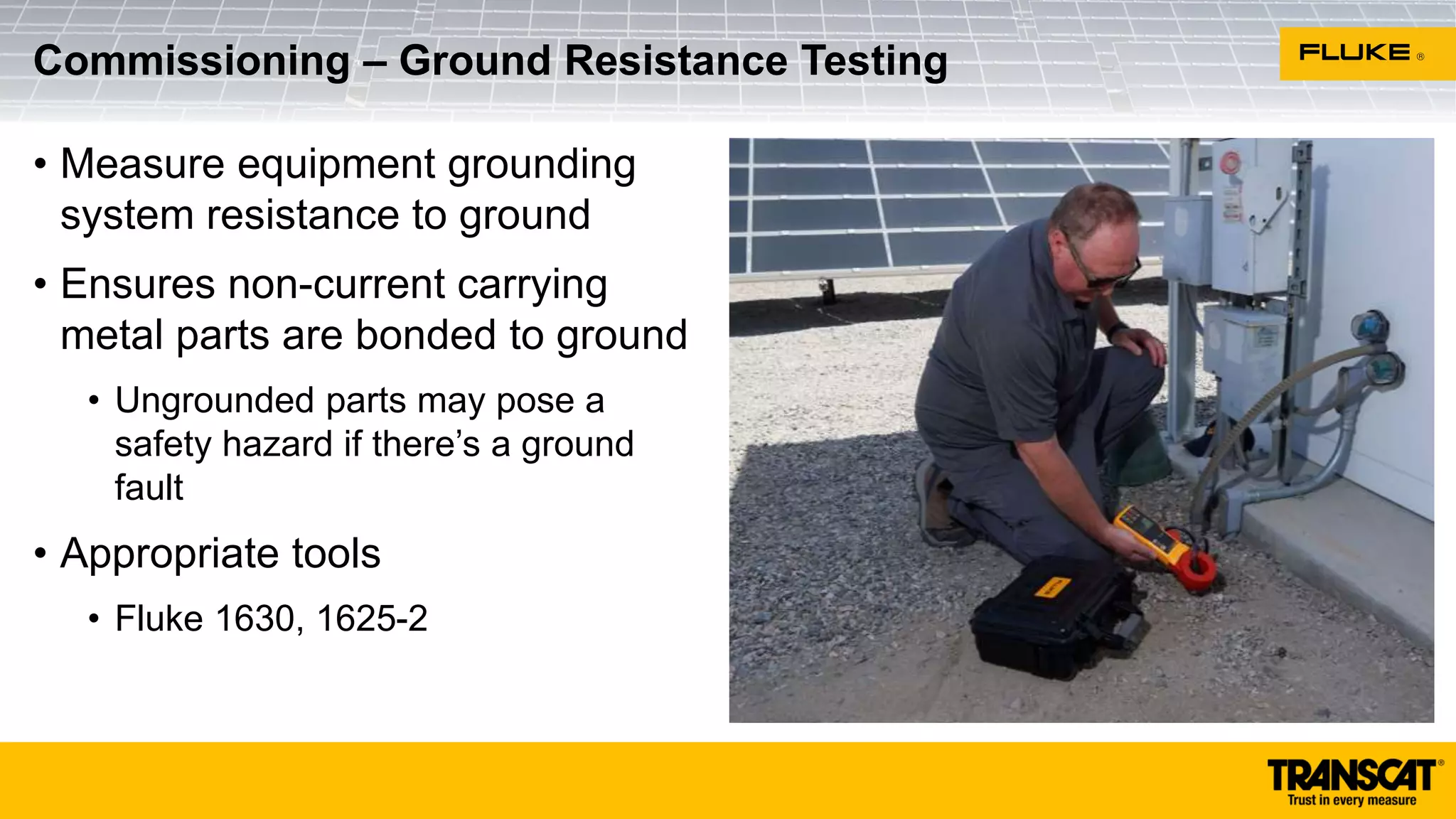

1) Test continuity of equipment and system grounding conductors

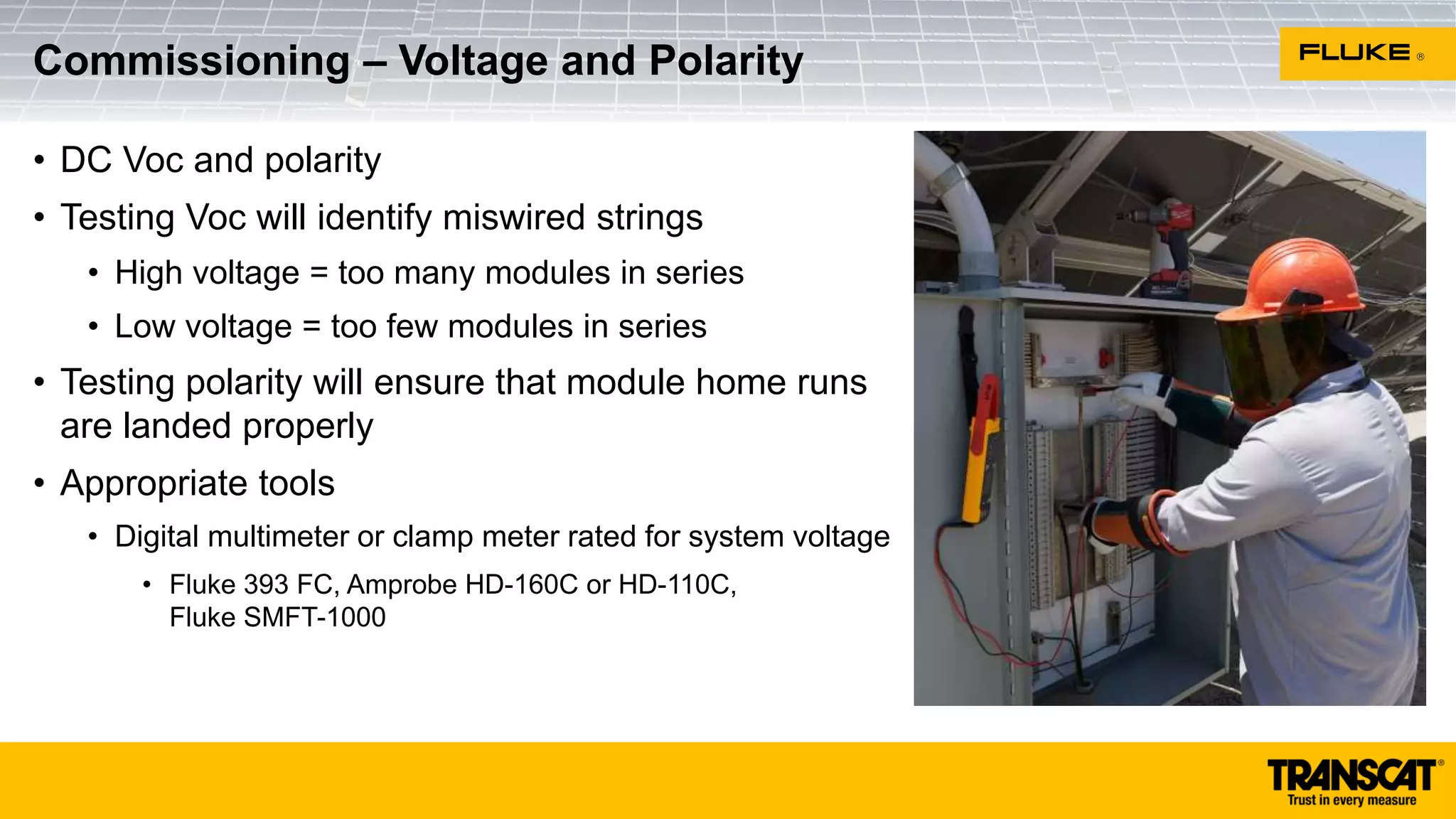

2) Test polarity of all DC cables

3) Test open-circuit voltage [Voc] for each PV source circuit

4) Test short-circuit current [Isc] for each PV source circuit

5) Test functionality of major system components

6) Test the insulation resistance of the DC circuit conductors

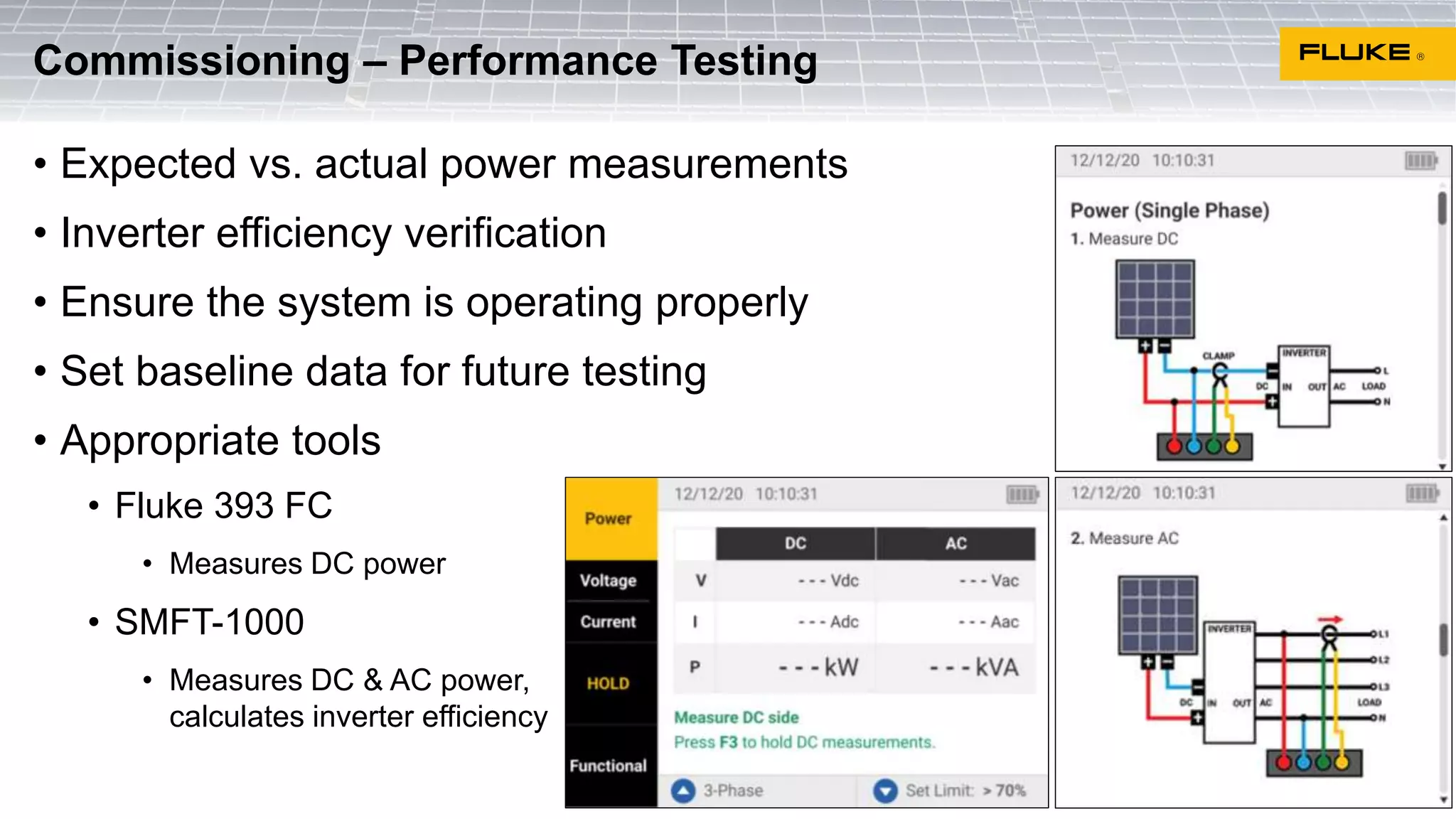

Performance

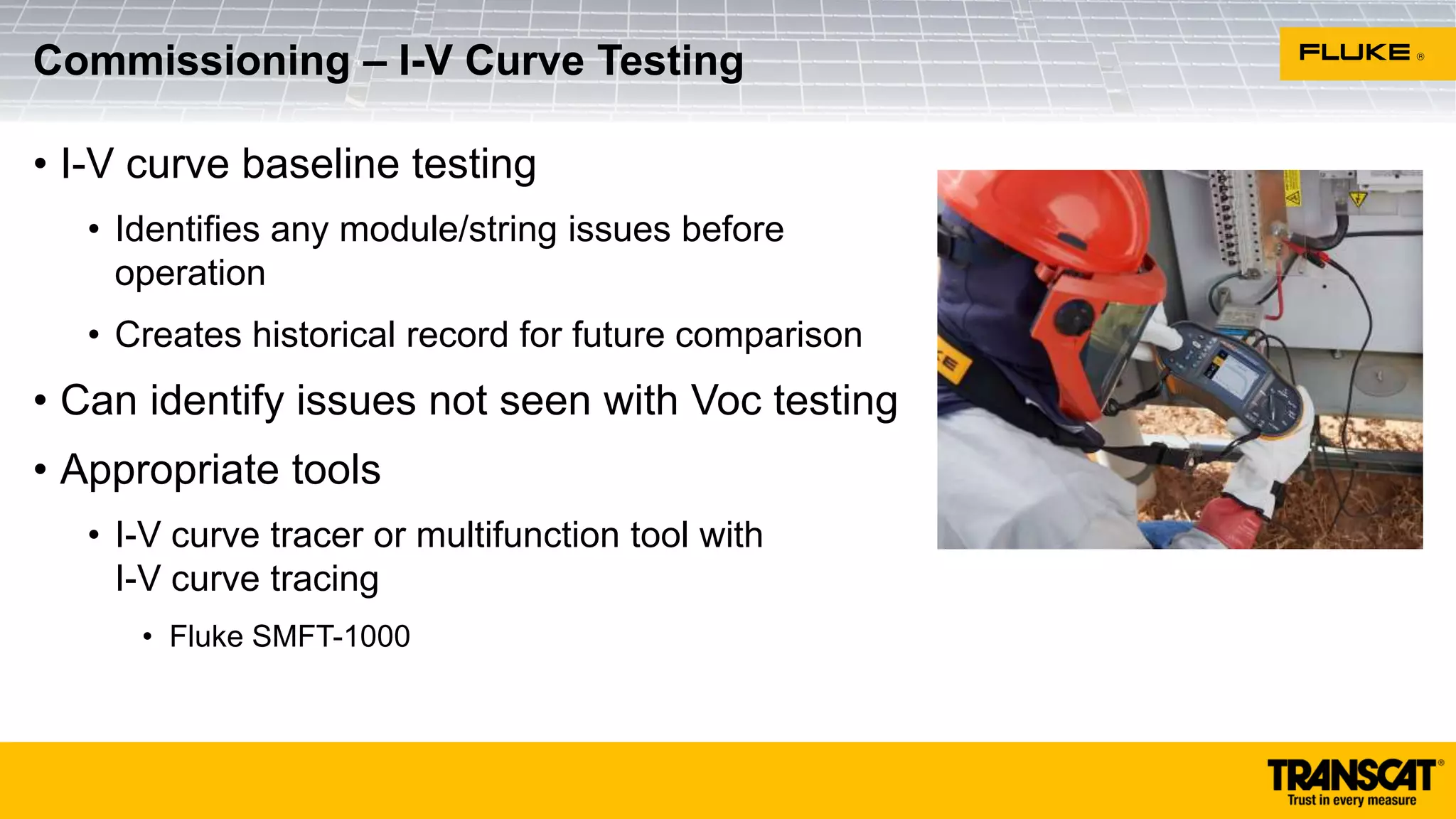

7) I-V Curve tracing and associated software analysis

IEC Testing Requirements for PV Systems

Utilities & 3rd

Party Service

Techs

PV Installers &

Maintenance Techs

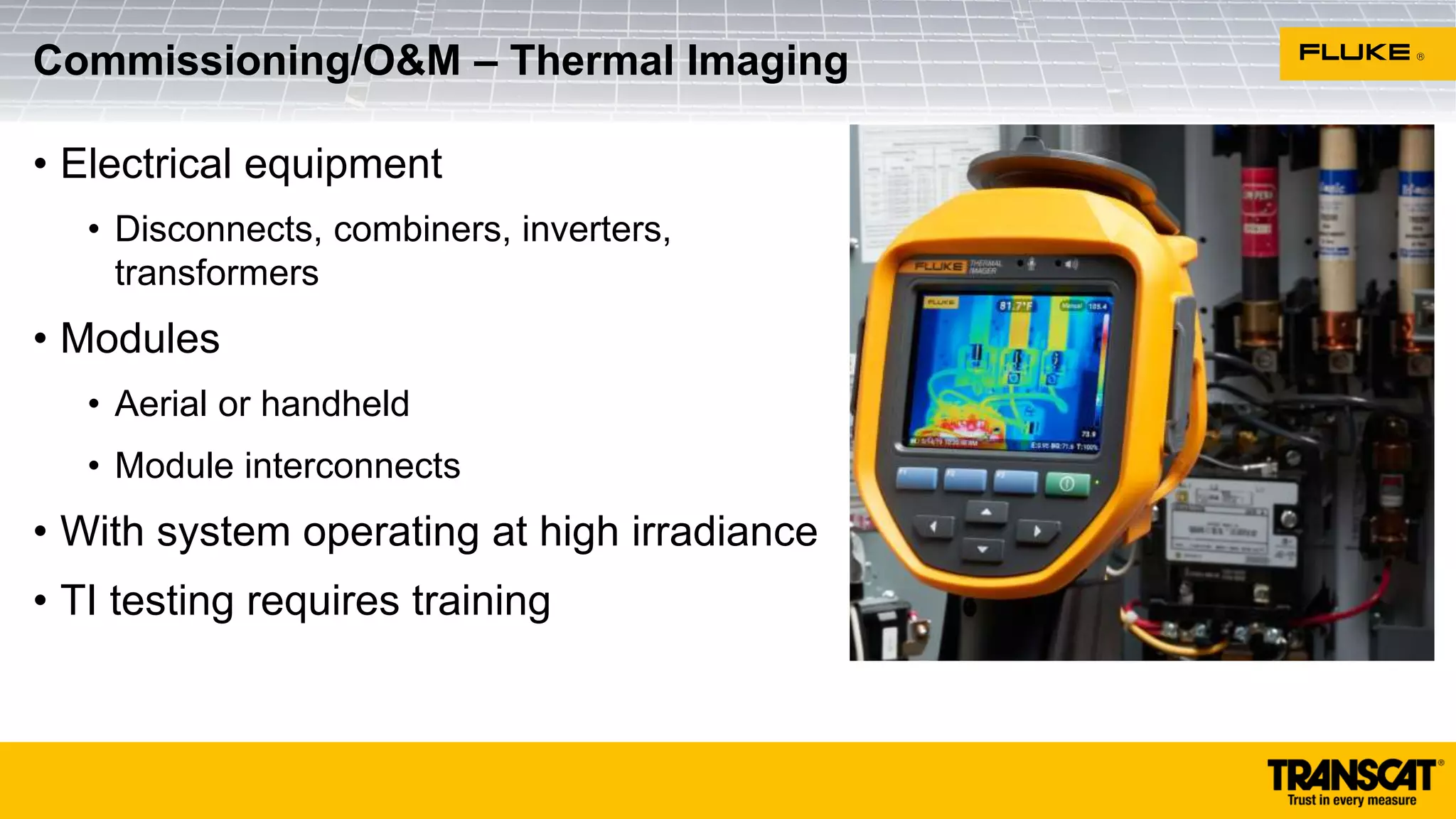

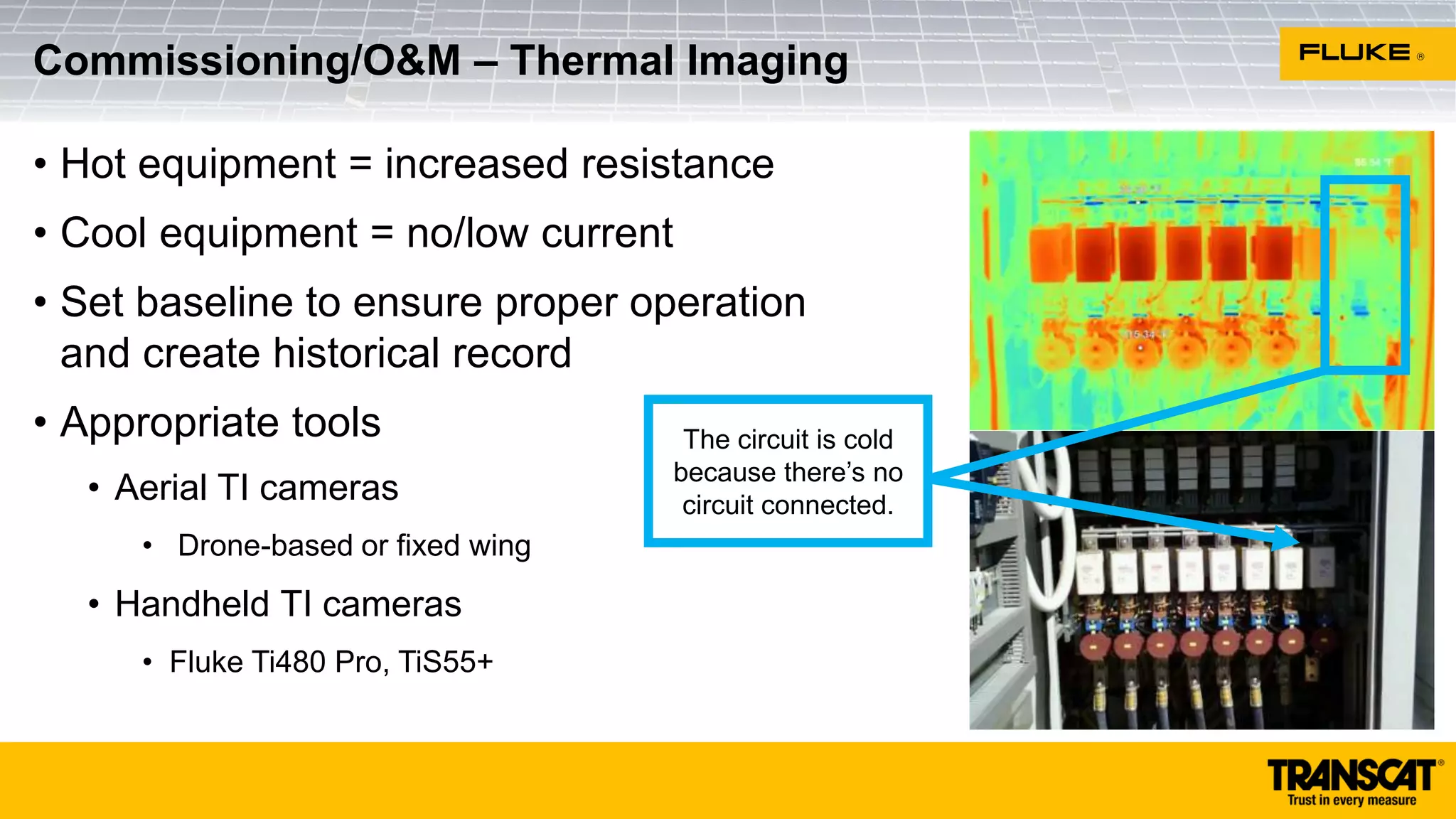

Safety and Performance testing during installation, commissioning and

maintenance ensures safety, reliability and longevity of PV installations](https://image.slidesharecdn.com/transcatnabcep2023presentationw-animations-tcat-230420200849-74b3a535/75/Tools-and-Techniques-for-Commissioning-and-Maintaining-PV-Systems-8-2048.jpg)