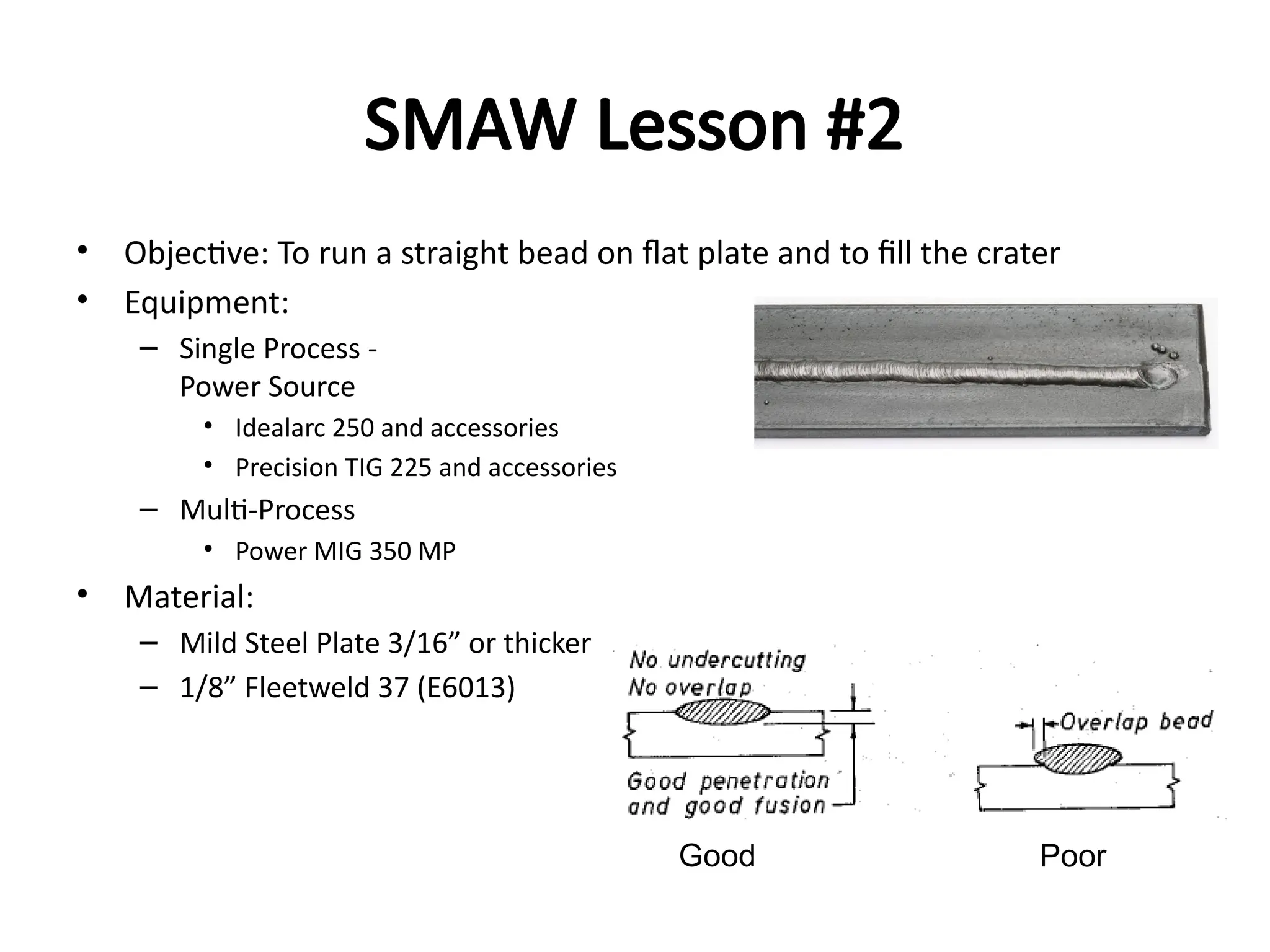

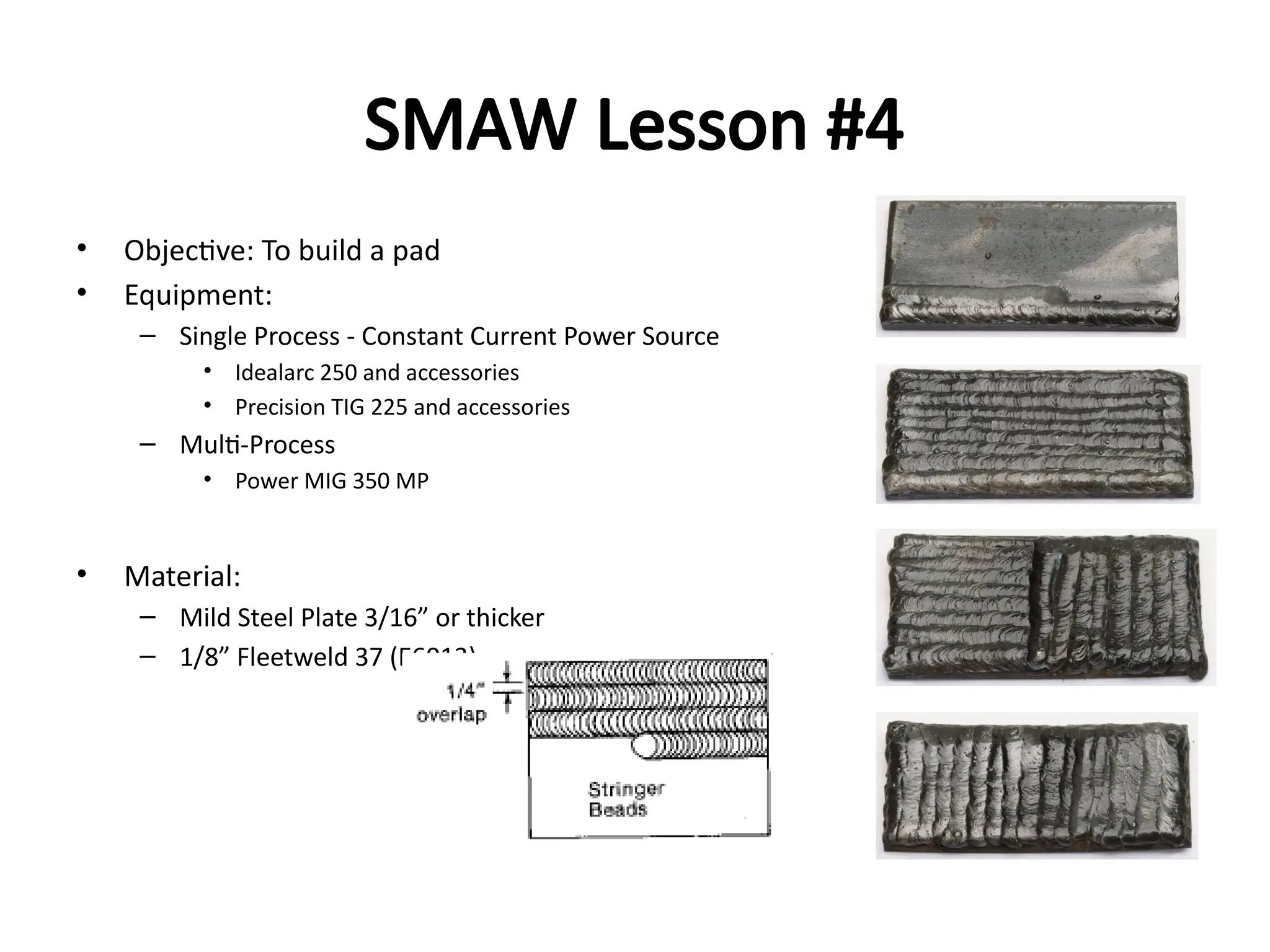

The document provides a comprehensive overview of Shielded Metal Arc Welding (SMAW), covering safety, equipment setup, welding techniques, and essential welding variables. It outlines the objectives for training welders, including proper arc striking, maintaining welds, and understanding welding techniques and classifications. The document also discusses advantages, limitations, and lesson plans for various welding tasks.