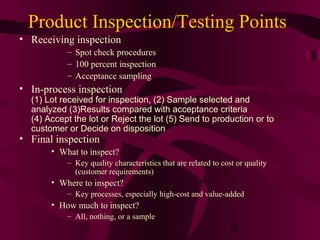

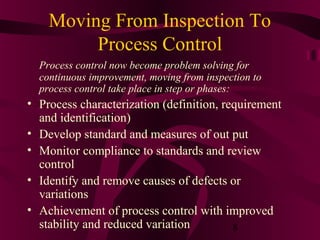

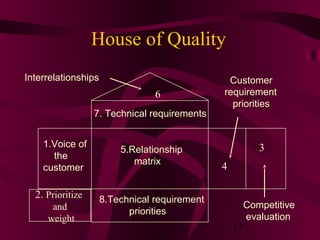

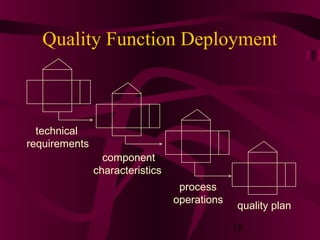

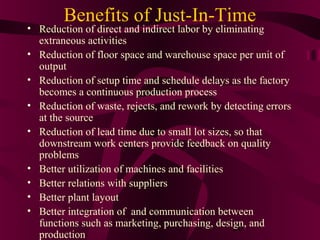

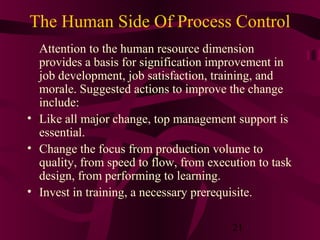

This document discusses process quality management. It examines key elements of process management including research and development, design, management of process quality for all work units and suppliers, systematic quality improvement and quality assessment. It also discusses the history of quality control and various quality control tools and techniques like statistical process control, Pareto analysis, quality function deployment, market research, and the benefits of just-in-time. It emphasizes the importance of controlling processes on a daily basis and moving from inspection to process control through problem solving for continuous improvement.