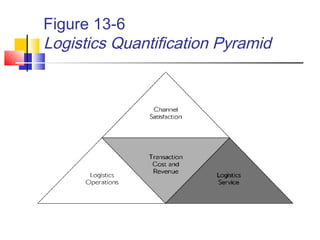

This chapter discusses the importance of performance measurement in supply chains. It explains that establishing metrics allows companies to understand how they are performing and identify areas for improvement. Good metrics should be consistent with company strategies and focus on customer needs. The chapter provides examples of different types of metrics companies can use to measure costs, inventory levels, customer service, and overall supply chain performance. These metrics can be classified in various categories and should be integrated both within and across companies to effectively drive improvement.