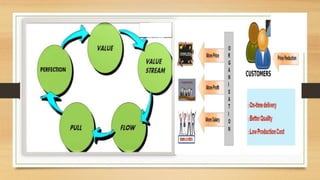

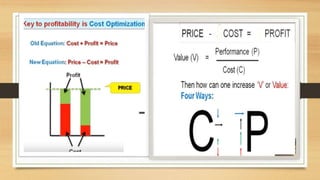

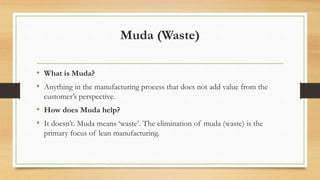

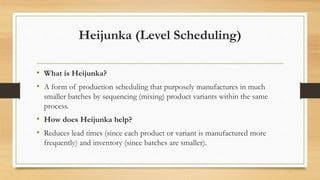

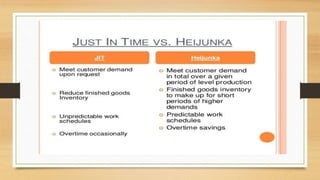

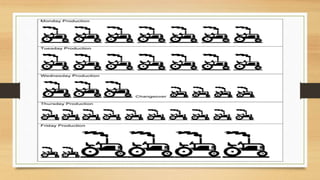

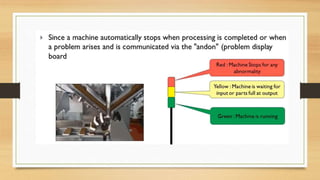

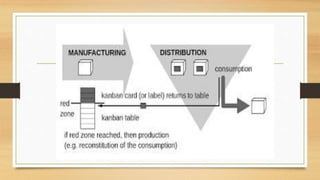

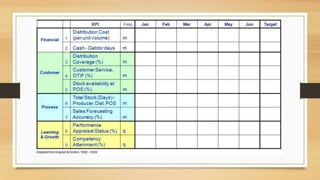

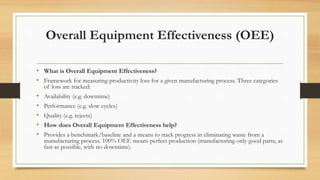

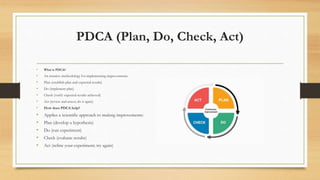

Lean manufacturing aims to reduce waste in production processes. It utilizes tools like 5S to organize workspaces, visual controls for communication, and just-in-time production to minimize inventory levels. Identification and elimination of sources of waste like defects, downtime, and excess inventory are key to improving overall equipment effectiveness through continuous improvement efforts.