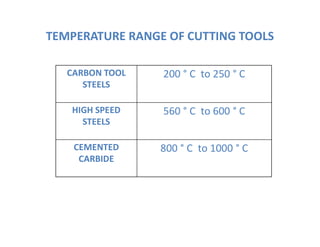

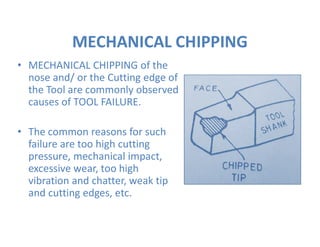

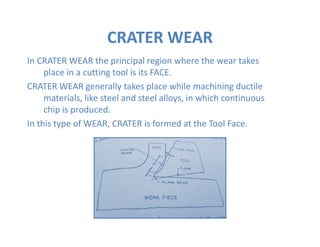

This document discusses tool failure and tool life in manufacturing. It identifies several indications of tool failure such as poor surface finish, higher power consumption, and dimensions not being produced as specified. Tool failure can occur due to thermal cracking, mechanical cracking, or gradual wear. Thermal cracking happens when heat during metal cutting causes the tool material to soften and crack. Mechanical cracking is due to high cutting pressure or impact. Gradual wear includes crater wear on the tool face and flank wear below the cutting edge.