The document discusses different types of timber, including their structures, classifications, sources, and properties. Some key points:

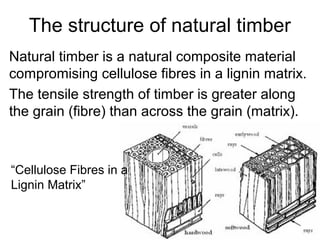

- Natural timber is composed of cellulose fibers in a lignin matrix, making it stronger along the grain.

- Timber is classified as hardwood or softwood based on whether it comes from deciduous or coniferous trees.

- Softwoods originate from coniferous evergreen trees and hardwoods from deciduous trees.

- Properties differ between softwoods and hardwoods such as cellulose/lignin content and fiber length.